Rolling brush assembly for steel formwork steel wire grinding machine in civil construction

A technology of steel formwork during construction, applied in grinding frames, grinders, manufacturing tools, etc., can solve the problems of high cost of roller brushes, occupation of manpower and material resources, and unstable fixing of wire brush heads, so as to reduce construction costs, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

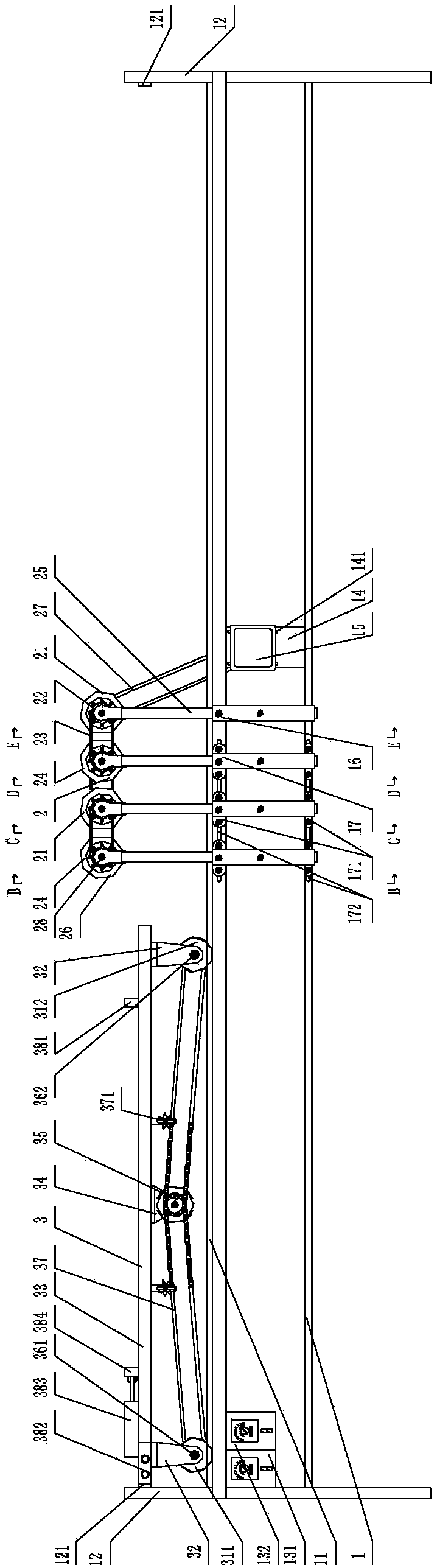

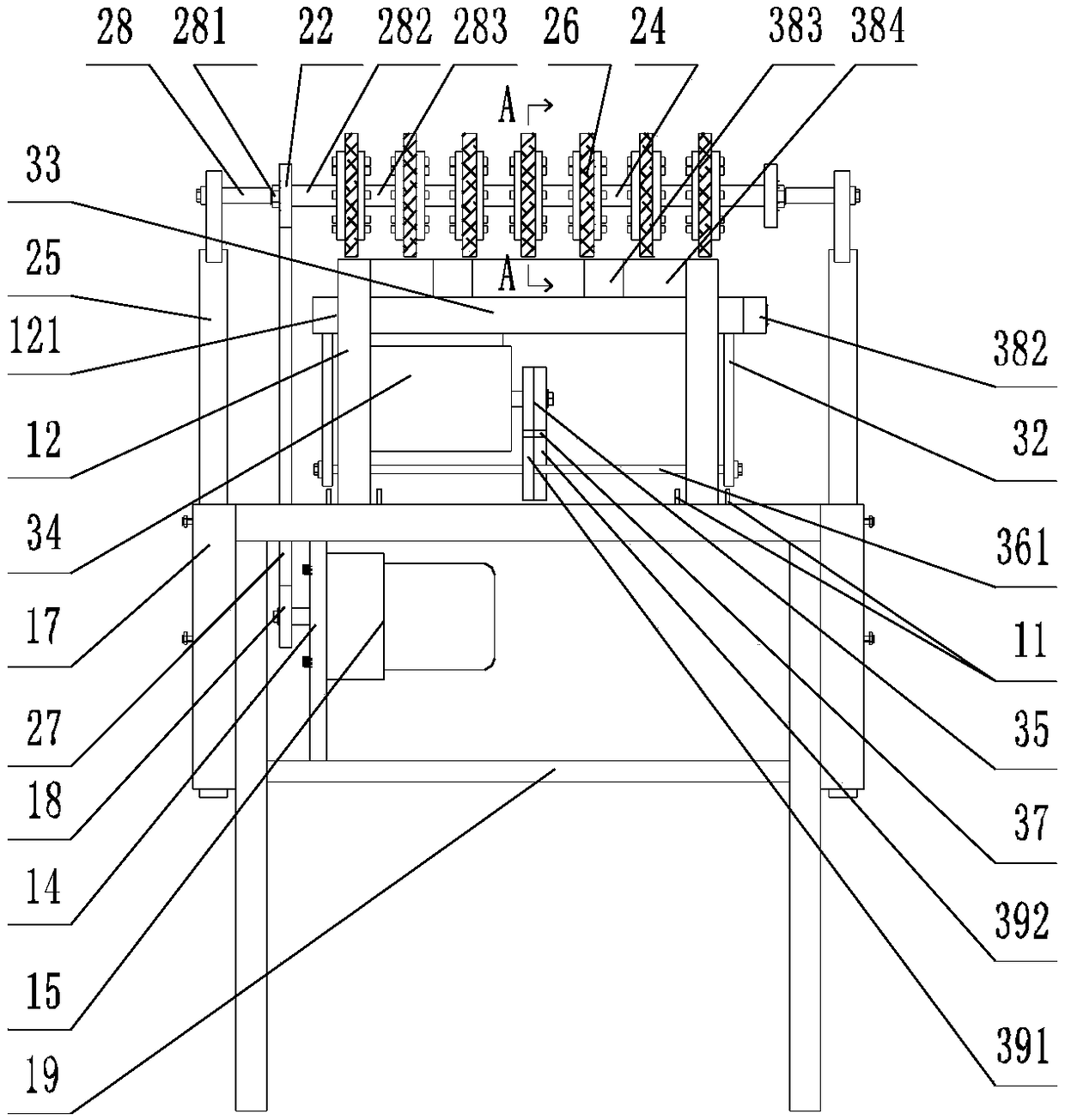

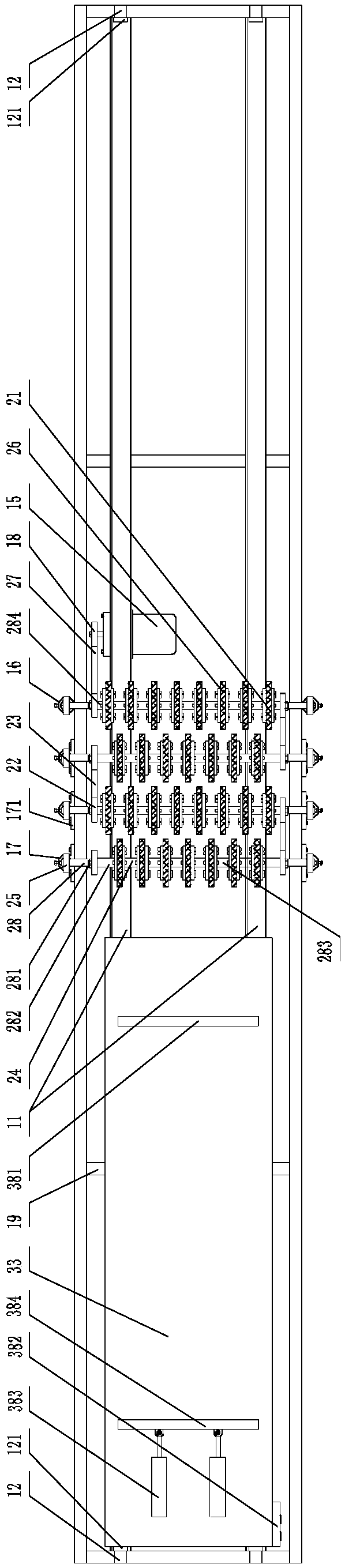

[0021] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

[0022] It should be noted that "up", "down", "left", "right", "front", and "rear" here are only exemplary directions defined for the convenience of describing the present invention, such as figure 1 As shown, the direction of the upper side of the paper is "Up", the direction of the lower side of the paper is "Down", the direction of the left side of the paper is "Left", the direction of the right side of the paper is "Right", and the direction of the back side of the paper is " "back", the direction of the front and side of the paper is "front", the direction of the left and right of the paper is "vertical", and the direction of the front and rear of the paper is "landscape". Of course, those skilled in the art understand on the basis of the present invention that directions such as "left" and "right" can also be defined in other ways, which also fall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com