Technology and device of refining brine through organic tubular membrane

A technology of refined brine and tubular membranes, applied in membrane technology, semi-permeable membrane separation, permeation/dialysis water/sewage treatment, etc., can solve the problems of short ceramic membrane cleaning cycle, narrow ceramic membrane channel, and easy breakage, and achieve The effect of long chemical cleaning cycle, slow flux decay speed and strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

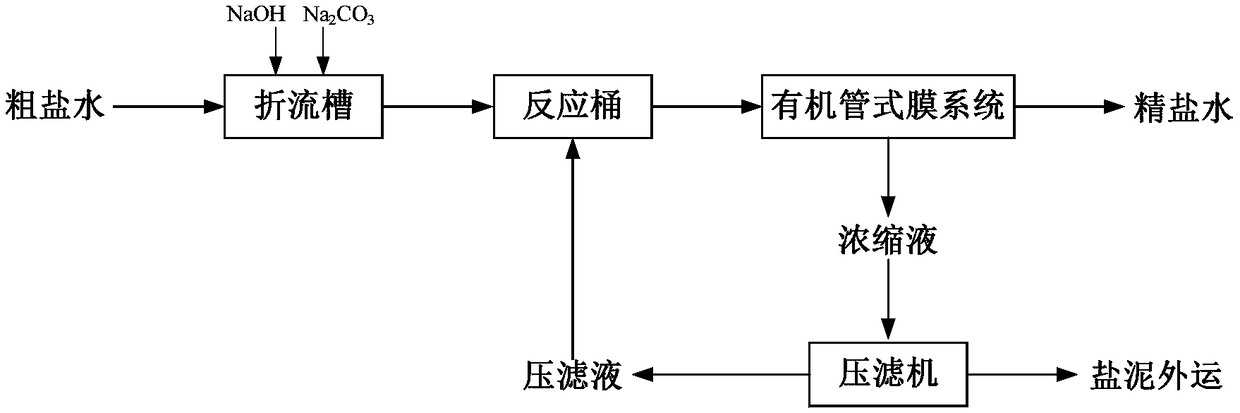

[0044] Such as figure 1 , 2 , Shown in 5, a kind of technique of organic tubular membrane refining brine, comprises the following steps: crude brine to be treated adds NaOH and NaOH in baffle tank 2 CO 3 Then it flows into the reaction tank, and the coarse brine in the reaction tank is sent to the organic tubular membrane system. The organic tubular membrane intercepts impurities such as suspended solids, colloids, and precipitates in the coarse brine, and the brine that passes through the organic tubular membrane is refined brine. The intercepted concentrated liquid is sent to the filter press, the pressed salt mud is transported outside for treatment, and the filtered liquid is returned to the reaction tank for recycling;

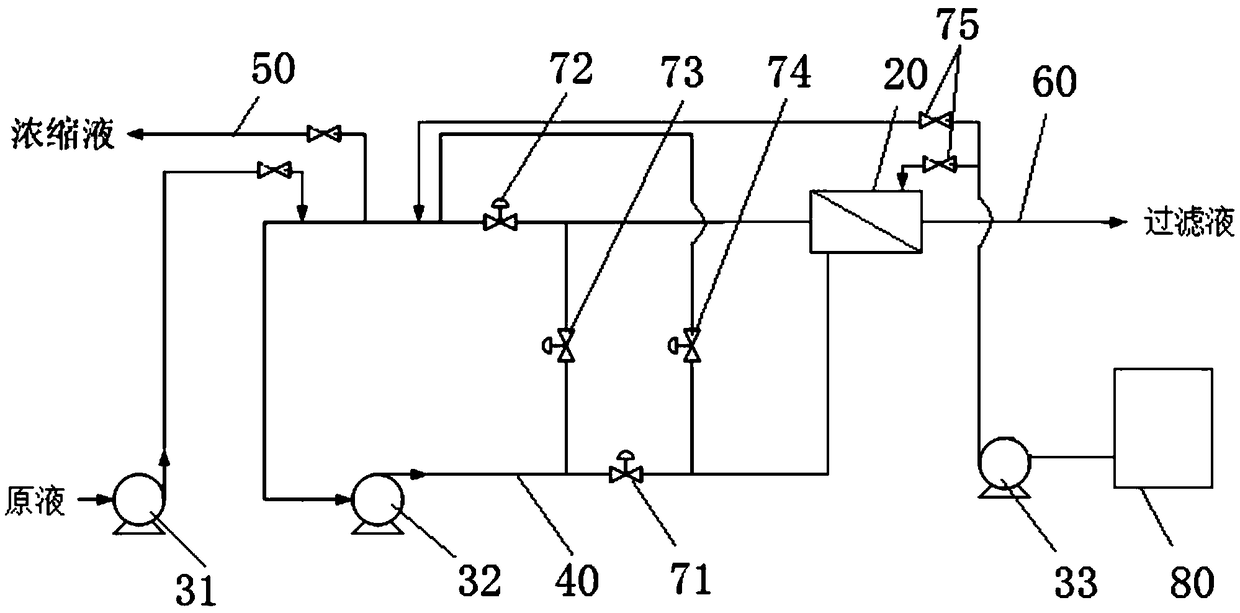

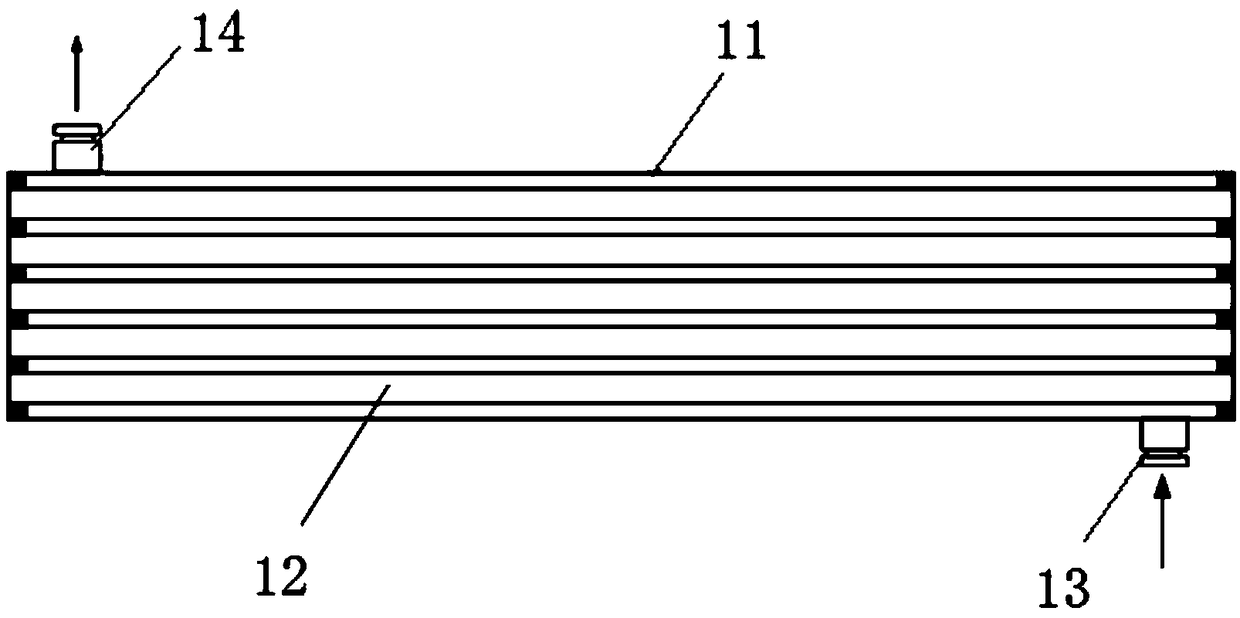

[0045] The organic tubular membrane system includes at least one organic tubular membrane stack 20, and the membrane stack inlet 21 and the membrane stack outlet 22 of the organic tubular membrane stack 20 are connected to a circulating pump 32 through ...

Embodiment 2

[0060] A device for purifying brine with organic tubular membrane, such as Figure 6 As shown, it includes the above-mentioned organic tubular membrane system 90, the raw liquid inlet port of the organic tubular membrane system 90 is connected with the outlet of the reaction barrel 103 of refined brine, and the filtrate outlet of the organic tubular membrane system 90 is connected to The refined brine tank 105 is connected, the concentrated liquid outlet of the organic tubular membrane system 90 is connected with the filter press 104, and the filter press outlet of the filter press 104 is connected with the reaction tank 103; the feed end of the reaction tank 103 passes through The baffle tank 102 is connected with the crude brine tank 101 .

Embodiment 3

[0062] The process of refining brine is as follows (such as figure 1 shown):

[0063] S1: The coarse brine to be treated is first sent into the baffle tank, and the refined NaOH and NaOH are metered into the baffle tank 2 CO 3 , and then flow into the reaction barrel, wherein, the Mg in the crude brine 2+ , Ca 2+ Respectively with NaOH, Na 2 CO 3 The reaction produces Mg(OH) 2 , CaCO 3 Solid matter; the amount of NaOH added is the same as Mg 2+ Excessive 0.1~0.3g / L after reaction, Na 2 CO 3 The amount added is the same as Ca 2+ Excessive 0.3-0.5g / L after reaction.

[0064] S2: The crude brine after the refining reaction is sent to the filtration system, and the organic tubular membrane stack intercepts impurities such as suspended solids, colloids, and sediments in the crude brine, and the brine that passes through the organic tubular membrane stack is the refined brine;

[0065] S3: The concentrated liquid intercepted by the organic tubular membrane stack is sent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com