Prefabricated inorganic man-made luminous stone slab and preparation method thereof

A luminous stone, artificial technology, applied in the field of plates, can solve the problems of rough maintenance and difficulty, and achieve the effect of reducing friction, improving wear resistance and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

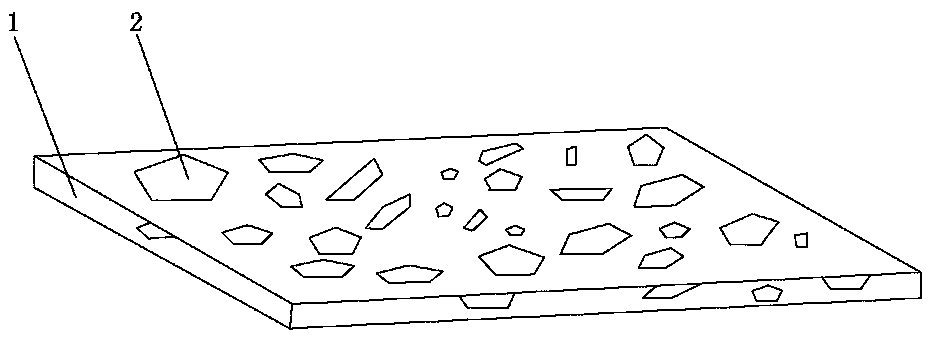

Image

Examples

Embodiment 1

[0020] A prefabricated inorganic artificial luminous stone plate, which is composed of the following components in parts by weight: 14 parts of Portland cement, 7 parts of calcined kaolin, 70 parts of calcium carbonate sand and luminous stone particle mixture, 5 parts of stone powder, and 15 parts of water , 6 parts of water reducing agent, 6 parts of magnesium oxide pigment. Among them, in the mixture of calcium carbonate sand and luminous stone particles, the ratio between calcium carbonate sand and luminous stone particles can be adjusted flexibly. For example, if the mixture of calcium carbonate sand and luminous stone particles is 70 parts in total, calcium carbonate sand can account for 20 parts. Parts, luminous stone particles account for 50 parts, or calcium carbonate sand accounts for 40 parts, then luminous stone particles account for 30 parts, or others, only need to ensure the total weight parts of the mixture of sand material and luminous stone particles.

[0021]...

Embodiment 2

[0027] A prefabricated inorganic artificial luminous stone slab, the stone slab is composed of the following components in parts by weight: 20 parts of Portland cement, 4 parts of calcined kaolin, 60 parts of quartz sand, 60 parts of luminous stone, and 3 parts of stone powder , 10 parts of water, 4 parts of water reducing agent, 3 parts of magnesium oxide pigment.

[0028] During the specific preparation, calcined kaolin, Portland cement, stone powder, quartz sand, luminous stone and magnesium oxide pigment are placed in the mixing tank for the first stirring, and the first stirring is stirred at a speed of 500 rpm for 4 minutes, stirring well.

[0029] Then add water and water reducer to the mixing tank and then carry out the second stirring. The second stirring is stirred at a speed of 1500 rpm for 5 minutes to obtain a uniformly stirred mixture.

[0030] Put the mixed material in the mold, use a press, press and shape, and shape the corresponding stone plate, and shape it...

Embodiment 3

[0034] A prefabricated inorganic artificial luminous stone slab, the stone slab is composed of the following components in parts by weight: 25 parts of composite portland cement, 1 part of calcined kaolin, 50 parts of quartz sand, 50 parts of luminous stone, 1 part of stone powder 6 parts of water, 2 parts of water reducer, 1 part of magnesium oxide pigment.

[0035] During the specific preparation, first put calcined kaolin, composite Portland cement, stone powder, quartz sand, luminous stone, and magnesium oxide pigment in the mixing tank for the first stirring, and the first stirring is at a speed of 1000 rpm 2 minutes, stirring well.

[0036] Then add water and water reducer in the mixing tank and then stir for the second time. The second stirring is stirred at a speed of 2000 rpm for 3 minutes to obtain a well-stirred mixture.

[0037] The mixture is placed in a mold and pressed into shape using a press.

[0038] Curing the molded product for 6 days;

[0039] Finally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com