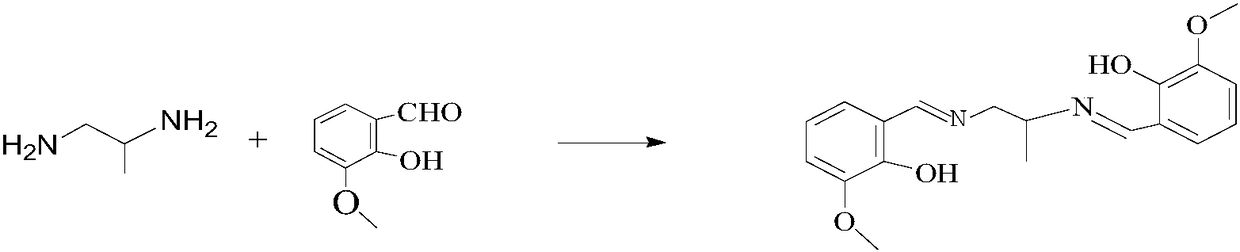

Preparation method of 1,2-diaminopropane o-vanillin double-Schiff base corrosion inhibitor

A technology of ortho-vanillin and bis-Schiff bases, applied in 1 field, can solve the problems of imperfect and mature Schiff base corrosion inhibitors, etc., and achieve good effect, high yield and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

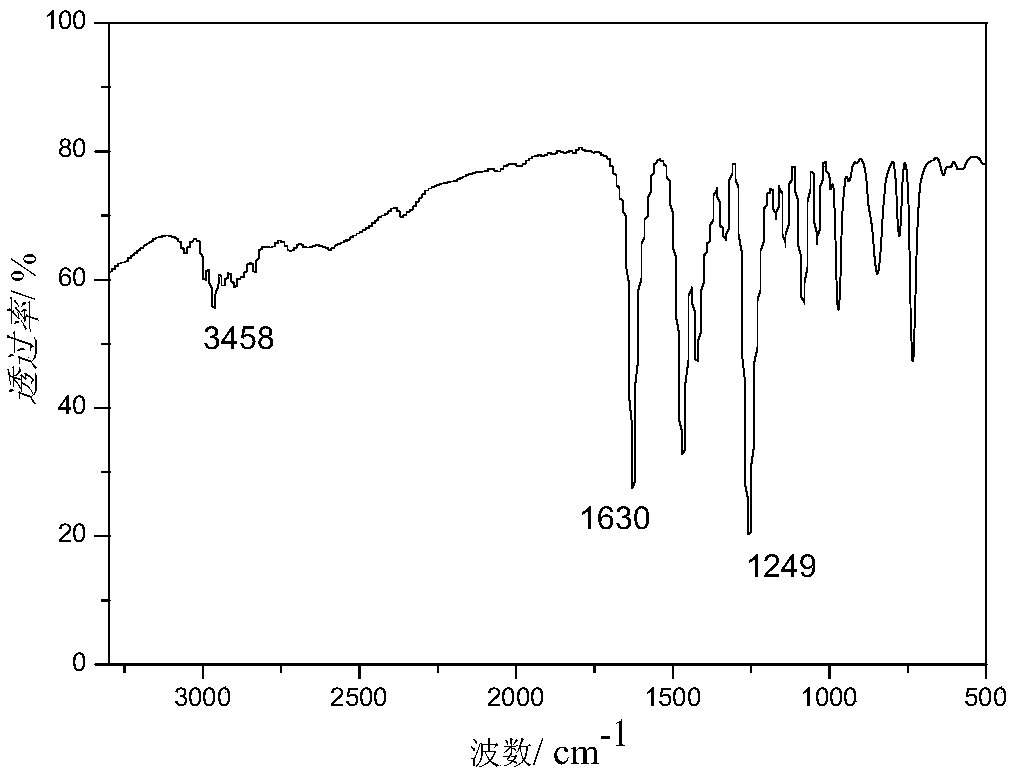

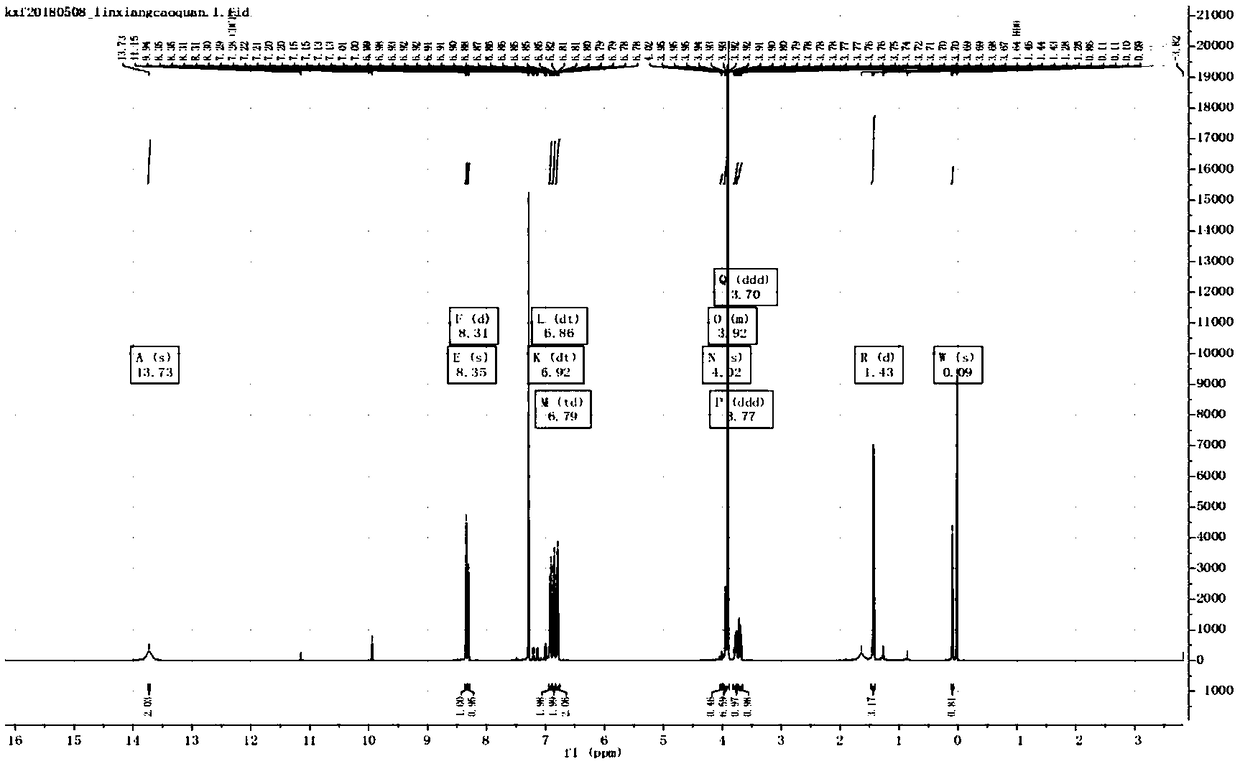

[0021] The specific steps for preparing the above-mentioned 1,2-propylenediamine adeno-vanillin bis-Schiff base corrosion inhibitor are:

[0022] (1) Measure 1.1411g of o-vanillin and place it in a round bottom flask filled with 15mL of absolute ethanol, and stir evenly with magnetic force.

[0023] (2) Add 0.1853g of analytically pure 1,2-propylenediamine and 0.15mL of analytically pure glacial acetic acid catalyst dropwise to the resultant of step (1), under constant temperature conditions of 65°C, magnetic stirring, reflux reaction for 6 hours, the whole process Nitrogen protection.

[0024] (3) Cool the solution obtained in step (2) at room temperature, a large amount of light yellow crystals are precipitated, filter under reduced pressure, continuously rinse with absolute ethanol, take out the filter cake, vacuum-dry the filter cake, and then put it into a In a beaker of 40mL of absolute ethanol, stir magnetically for 2 hours to remove excess o-vanillin, glacial acetic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com