Polymerization method of reactive black dye KN-B

A high-molecularization and reactive black technology, applied in the field of functional polymer material synthesis, can solve the problems of affecting the polymerization reaction, high cost, poor adaptability and diversity, etc., and achieve pure products, large operating freedom and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the embodiments.

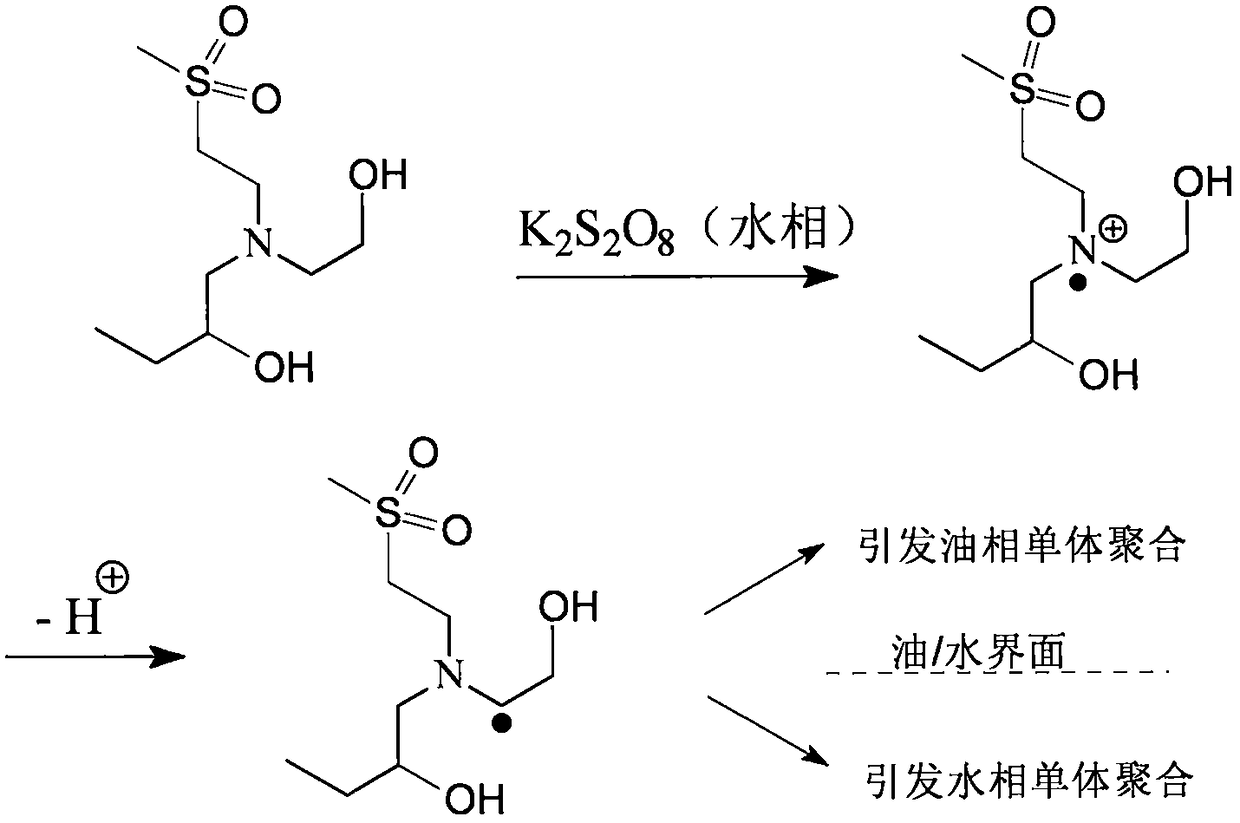

[0020] Preparation of functional initiator:

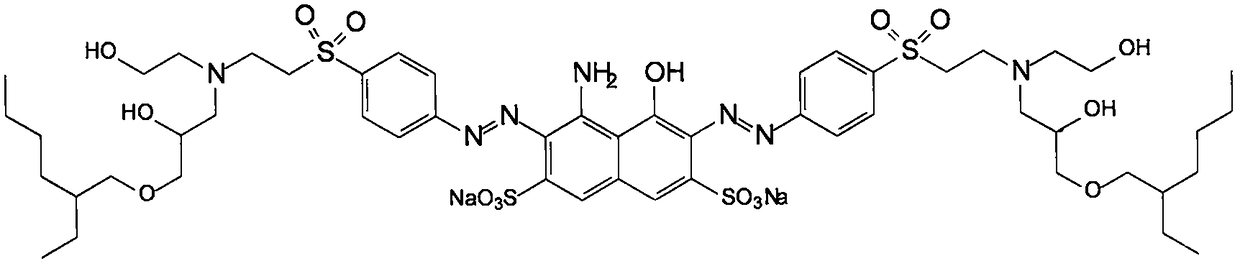

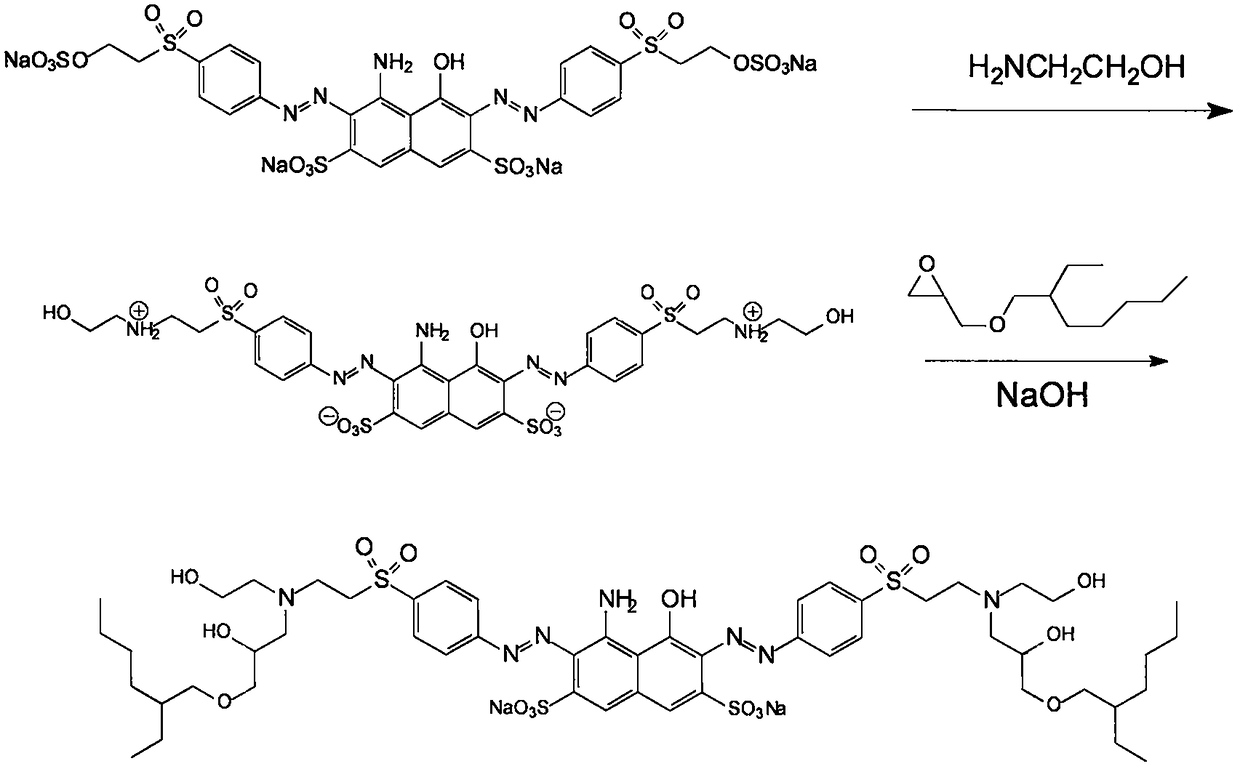

[0021] Reactive black KN-B is used as the starting material. This material has been commercialized, so its preparation has a ready-made method, which will not be repeated here. The following are the specific preparation steps:

[0022] 1) Dissolve 0.1 mol of reactive black KN-B in 300 ml of water, gradually add 0.22 mol of ethanolamine under stirring, control the temperature of the reaction solution in the range of 50-55°C, and the reaction time within 3-4 hours. After the reaction is completed, cool to 4~ At 8°C, the product will precipitate in the form of internal salt, which is washed with a small amount of ethanol after filtration;

[0023] 2) Disperse the product obtained from the previous reaction in 300 ml of absolute ethanol, add 0.2 mol of solid NaOH and 0.2 mol of isooctyl glycidyl ether under stirring, and react at 55 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com