Processing method of high-stability antistatic agent for plastics

A high stability, antistatic agent technology, applied in the field of plastic processing, can solve the problems affecting the quality of plastic mechanics, etc., to achieve the effect of improving antistatic ability, reducing resistance value and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

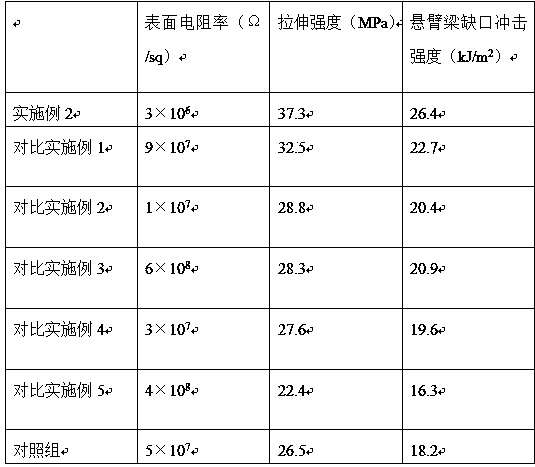

Examples

Embodiment 1

[0032] A processing method of high stability antistatic agent for plastics, comprising the steps of:

[0033] (1) Preparation of anti-electricity reinforcing material:

[0034] a. Put the mica powder into the ball mill for ball milling, take out after completion and pass through a 2500 mesh sieve to obtain fine mica powder for later use;

[0035] b. Put the fine-grained mica powder obtained in operation a into a calciner for calcining treatment, control the calcining temperature to 740°C, and take it out after 1 hour for later use;

[0036] c. Put the polystyrene and the fine-grained mica powder treated in operation b together into the incinerator, keep enough oxygen in the incinerator, heat to 1000°C, and take out the mixture A after fully burning for later use;

[0037] d. Mix pyrrole and ethanol aqueous solution according to the volume ratio of 1:90 and put them into the reactor, then put the mixture A prepared in operation c into the reactor, and put the reactor under ice...

Embodiment 2

[0051] A processing method of high stability antistatic agent for plastics, comprising the steps of:

[0052] (1) Preparation of anti-electricity reinforcing material:

[0053] a. Put the mica powder into the ball mill for ball milling, take out after completion and pass through a 2500 mesh sieve to obtain fine mica powder for later use;

[0054] b. Put the fine-grained mica powder obtained in operation a into a calciner for calcining, control the calcining temperature to 750°C, and take it out after 1.3 hours for later use;

[0055] c. Put the polystyrene and the fine-grained mica powder treated in operation b together into the incinerator, keep enough oxygen in the incinerator, heat to 1050°C, and take out the mixture A after fully burning for later use;

[0056] d. Mix pyrrole and ethanol aqueous solution according to the volume ratio of 1:93 and put them into the reactor, then put the mixture A prepared in operation c into the reactor, and put the reactor under ice bath c...

Embodiment 3

[0070] A processing method of high stability antistatic agent for plastics, comprising the steps of:

[0071] (1) Preparation of anti-electricity reinforcing material:

[0072] a. Put the mica powder into the ball mill for ball milling, take out after completion and pass through a 2500 mesh sieve to obtain fine mica powder for later use;

[0073] b. Put the fine-grained mica powder obtained in operation a into a calciner for calcining, control the calcining temperature to 760°C, and take it out after 1.5 hours for later use;

[0074] c. Put the polystyrene and the fine-grained mica powder treated in operation b together into the incinerator, keep enough oxygen in the incinerator, heat to 1100°C, and take out the mixture A after fully burning for later use;

[0075] d. Mix pyrrole and ethanol aqueous solution according to the volume ratio of 1:95 and put them into the reactor, then put the mixture A prepared in operation c into the reactor, and put the reactor under ice bath c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com