Use of a pyran derivative and its preparation method

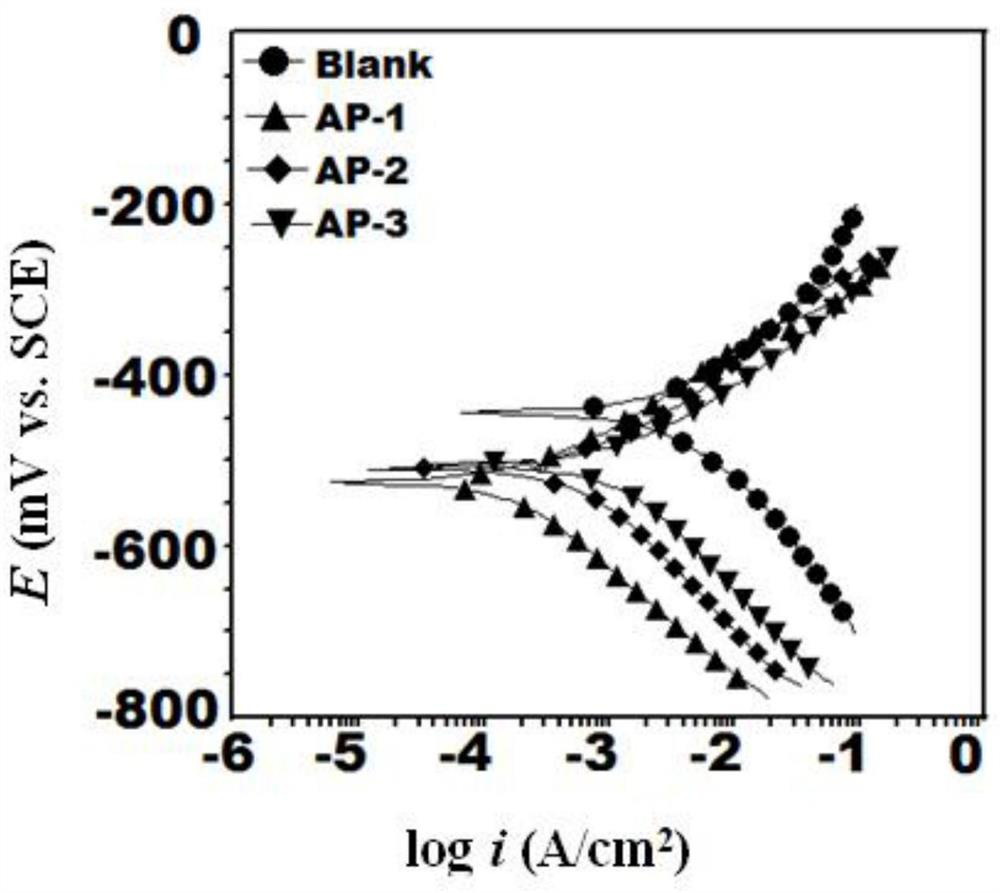

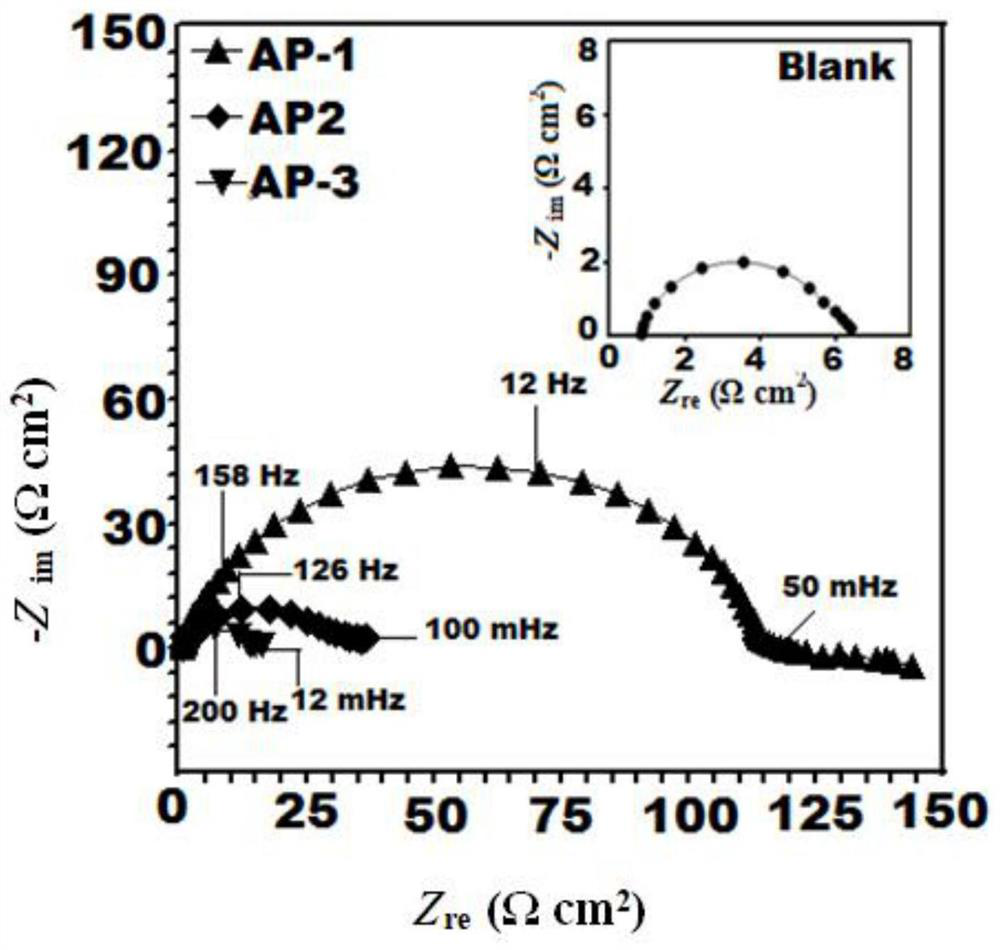

A technology of pyran derivatives and their uses, which is applied in the fields of uses and preparations of pyran derivatives, can solve the problems of propynyl alcohol polluting the environment, achieve good corrosion inhibition efficiency, improve adsorption capacity, and inhibit corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

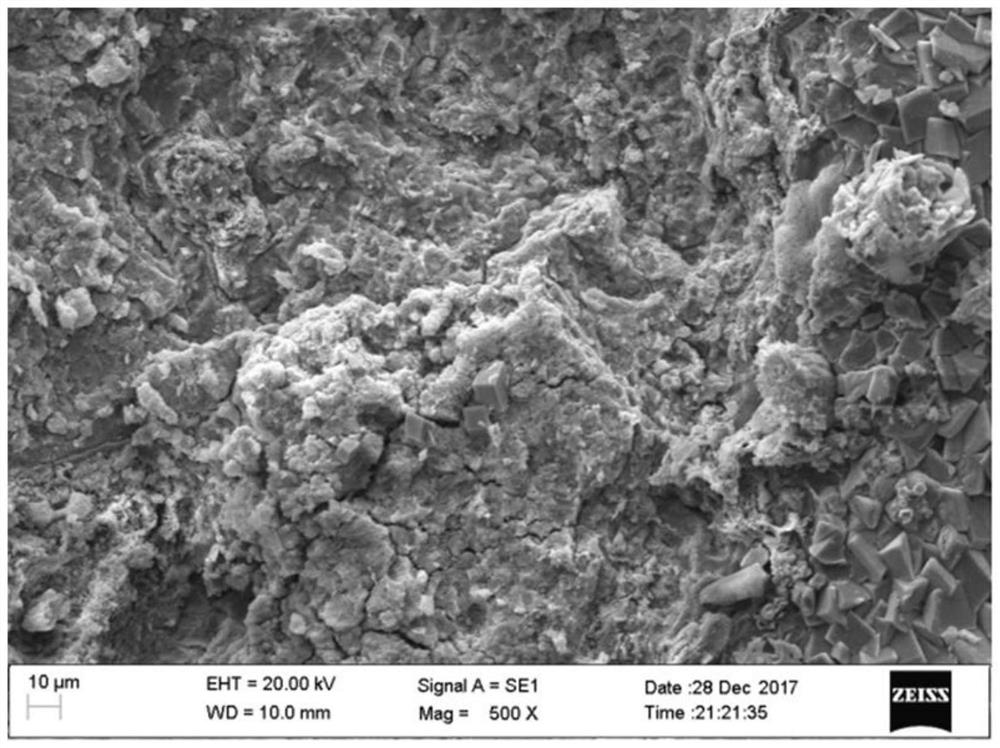

Examples

Embodiment 1

[0045] A method for preparing pyran derivatives, the method comprising:

[0046] In a 50m round bottom flask, add 4-methoxybenzaldehyde / benzaldehyde / 4-nitrobenzaldehyde (1mmol), malononitrile (1mmol) and dimedone (1mmol), and 25mL of water and catalyst piperpene Pyridine (2 drops), mix them evenly, stir at room temperature for 30-45 minutes, collect the formed precipitate by filtration, and recrystallize with ethanol to obtain the pyran derivative AP-1.

Embodiment 2

[0048] A preparation method of pyran derivatives, the method is basically the same as Example 1, the difference is that 4-methoxybenzaldehyde is replaced by 4-methylbenzaldehyde.

Embodiment 3

[0050] A preparation method of pyran derivatives, the method is basically the same as Example 1, the difference is that 4-methoxybenzaldehyde is replaced by 4-ethylbenzaldehyde.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com