Water-based cleaning agent with iron rust and copper rust removing function as well as preparation method thereof

A water-based rust removal technology, applied in the field of metal cleaning agents, can solve the problems that iron and copper oxides and flux residues cannot be completely cleaned, and achieve the effect of excellent cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh the raw materials according to the proportion, and the mass percentage of each raw material is: 2% nitric acid, 2% citric acid, 1% fatty alcohol polyoxyethylene ether, 1% thiourea, 1% tetrasodium edetate , 0.2% 726 defoamer, and the rest is water.

[0025] First add water to mix and add, stir until completely dissolved.

[0026] The cleaning agent prepared in this example was tested for degreasing rate, foam performance and hydrophilic performance respectively, and the results are shown in Table 1.

Embodiment 2

[0028] Weigh the raw materials according to the ratio, and the mass percentage of each raw material is: 3% phosphoric acid, 3% EDTA, 1% fatty alcohol polyoxyethylene ether, 1% succinic acid, 1% tetrasodium ethylenediaminetetraacetic acid , 0.2% 726 defoamer, and the rest is water.

[0029] First add water to mix and add, stir until completely dissolved.

[0030] The cleaning agent prepared in this example was tested for degreasing rate, foam performance and hydrophilic performance respectively, and the results are shown in Table 1.

Embodiment 3

[0032] The raw materials are weighed according to the ratio, and the mass percentages of each raw material are: 4% sulfuric acid, 4% HEDP, 1% fatty alcohol polyoxyethylene ether, 1% thiourea, 1% tetrasodium edetate, 0.2% 726 defoamer, the rest is water.

[0033] First add water to mix and add, stir until completely dissolved.

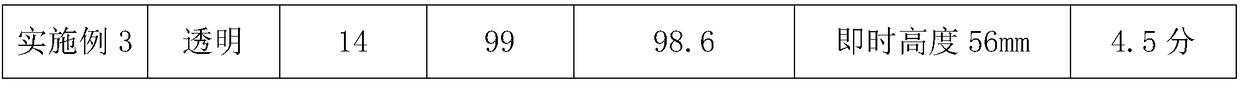

[0034] The cleaning agent prepared in this example was tested for degreasing rate, foam performance and hydrophilic performance respectively, and the results are shown in Table 1.

[0035] Evaluation method:

[0036] a. Derusting appearance: visually evaluate the flux residue on the surface of the copper tube and the surface of the welding part.

[0037] Judgment criteria:

[0038] Level 0: Complete removal of more than 98%

[0039] Level 1: Complete removal (90-98%)

[0040] Level 2: Complete removal (70-90%)

[0041] Level 3: Complete removal (50-70%)

[0042] Level 4: Complete removal (30-50%)

[0043] Level 5: Complete removal (0-30%)

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com