Ballast bed at level intersection of railway and highway and preparation method thereof

A technology of level crossing and manufacturing method, applied in the field of rail transit, can solve the problems of interfering with the normal transportation order of railways and highways, increasing the maintenance workload and investment, etc., and achieving a balanced and reliable working state, a simple structure, and strong durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

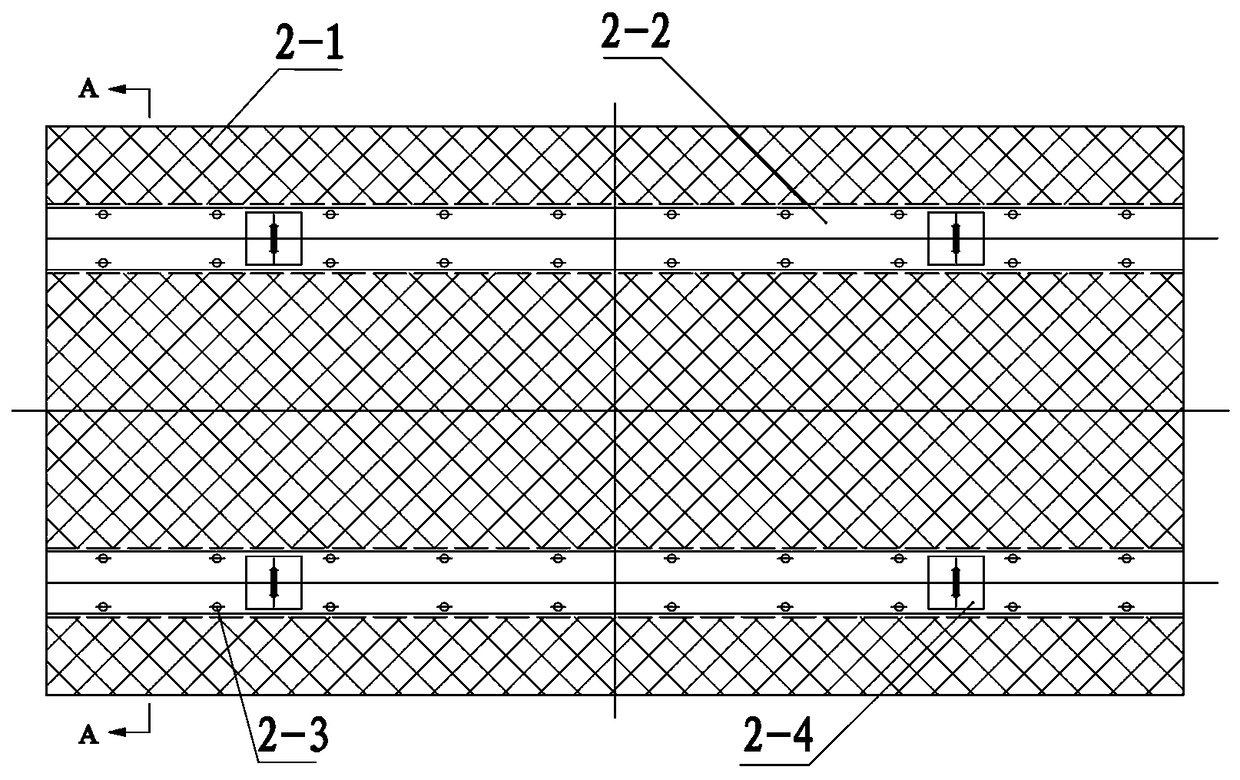

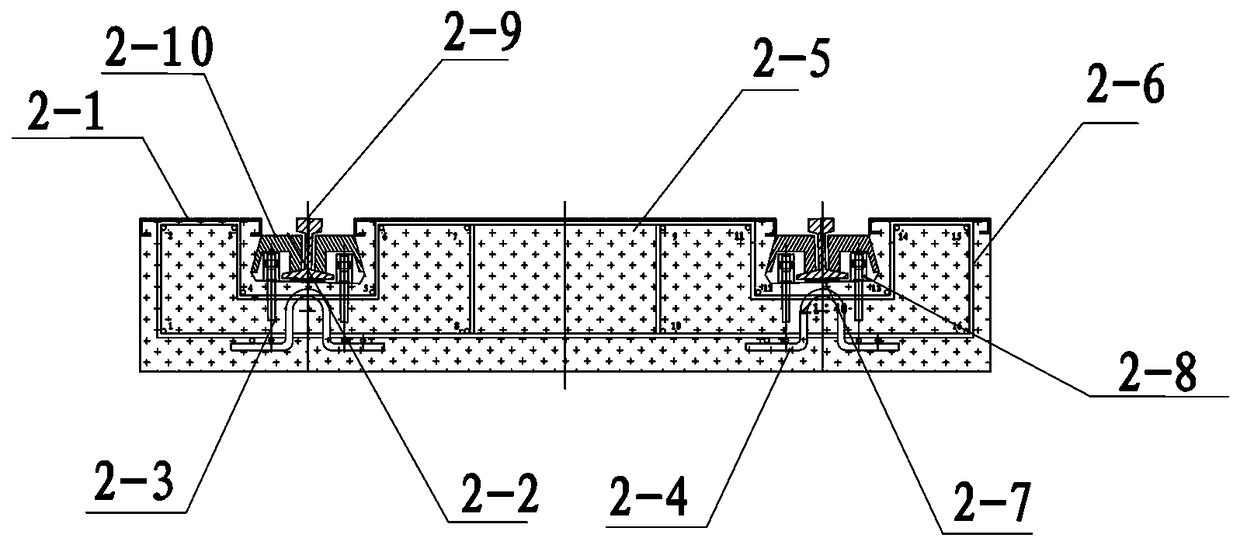

[0033] Such as Figure 1-Figure 7 As shown, a railway and highway level crossing track bed of the present invention comprises a base 1 and a concrete track bed 2, and the concrete track bed 2 is placed above the base 1, and is characterized in that the concrete track bed 2 consists of more than one block-type The track plate units are spliced together, and each segmented track plate unit is a rectangular track plate, including a steel cage 2-6, a patterned mesh plate 2-1 welded on the top of the steel cage 2-6, and set on the steel cage 2-6. The inner rail bearing groove 2-2, the screw spike 2-3, the insulating sleeve 2-8 and the concrete layer 2-5,

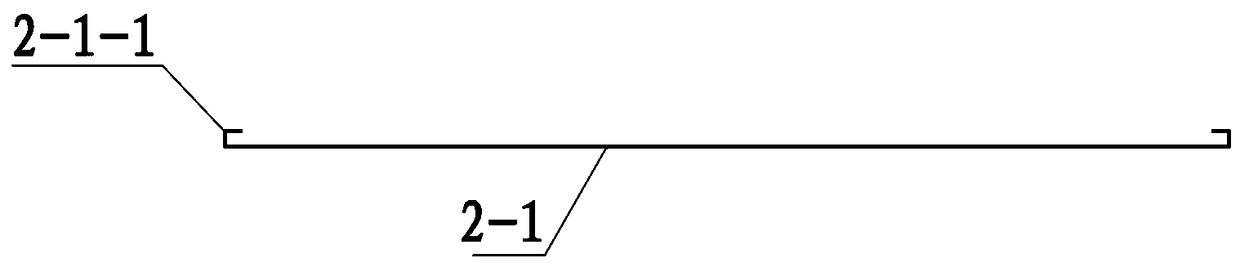

[0034] The two ends of the patterned mesh plate 2-1 are bent edges 2-1-1, which are wrapped on the two ends of the reinforcement cage 2-6, and at least two or more rail bearing grooves are reserved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com