Surface shape detection method for optical free curved surface with large offset

A detection method and technology of deviation, which are applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problem of inability to realize the detection of optical free-form surfaces with large deviations, and avoid complex three-dimensional topography, simple system structure, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] A method for measuring the shape of an optical free-form surface with a large deviation, comprising the following specific steps in sequence:

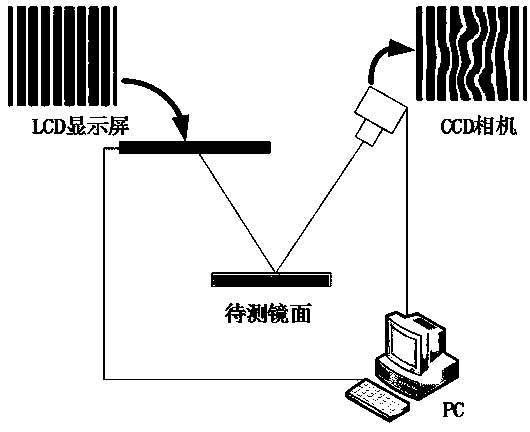

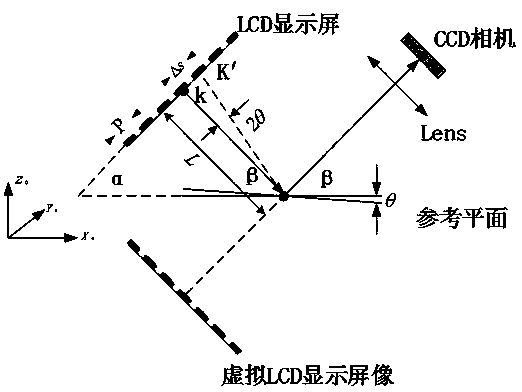

[0037] Step 1, follow figure 1 Schematic diagram of the detection device structure to build an experimental system, based on the time phase expansion method to obtain its continuous phase distribution data. The specific process is as follows:

[0038] First, the computer controls to generate a series of coded stripes with different frequencies, which are displayed on the LCD screen and irradiated onto the reference plane, and recorded by the CCD camera. The tth (t=(0,1,2,...s)) stripe pattern can be expressed as follows:

[0039] g 0 (x,y;t)=a(x,y;t)+b(x,y;t)cos[2π(f 0 +△fx)t] (12)

[0040] Among them, a is the background light intensity; b is the amplitude modulation; △f and f 0 +△f represent the specific frequency and time carrier frequency of the observed fringe pattern, respectively.

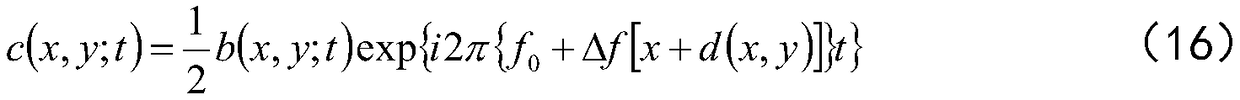

[0041] Step 2. Demodulate the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com