Device for automatically checking and controlling acid-base concentration online in etching pipeline

An automatic inspection and assembly line technology, which is applied in measuring devices, non-electric variable control, various fluid ratio control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The accompanying drawings disclose the basic structure and working process of the embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

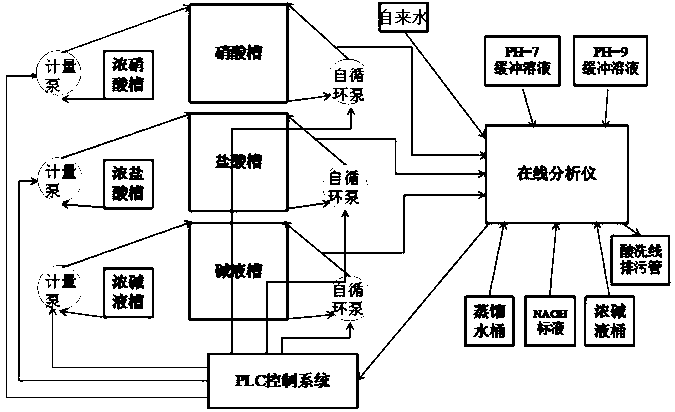

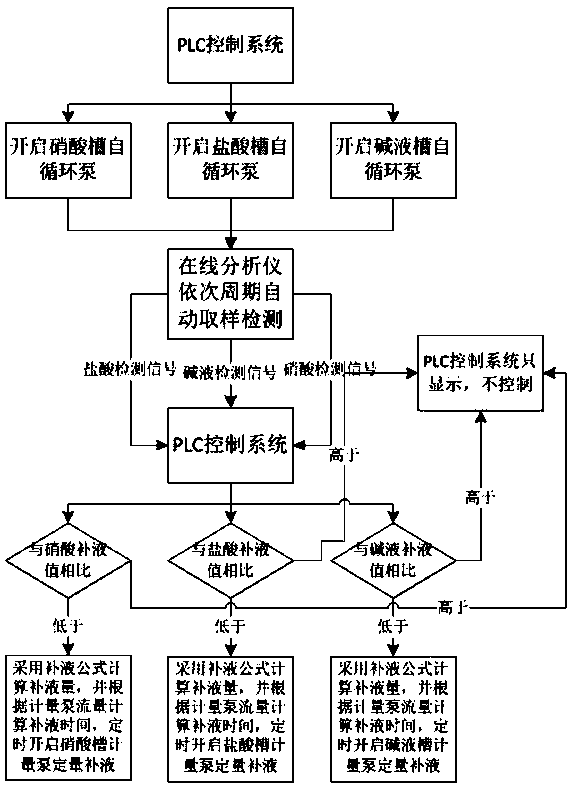

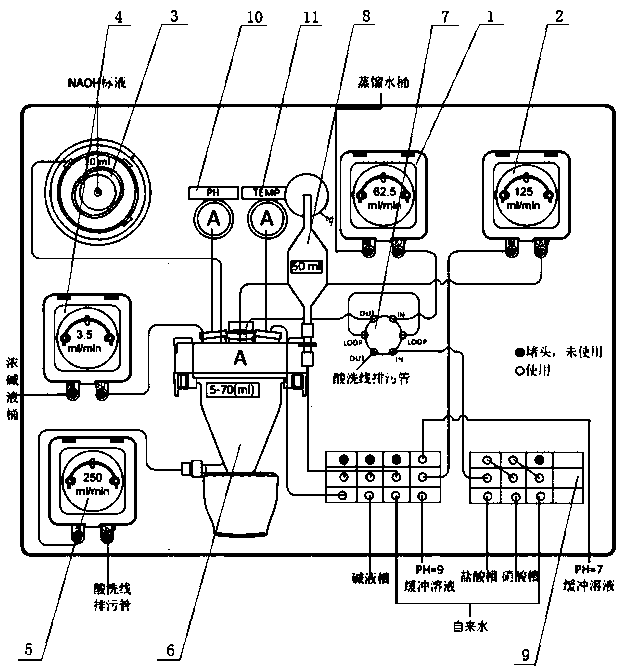

[0027] Depend on figure 1 It can be seen that the present invention includes independent nitric acid tanks, hydrochloric acid tanks and lye tanks in the assembly line, and independent self-circulating pumps for each tank, and also includes correspondingly matched concentrated nitric acid tanks, concentrated hydrochloric acid tanks, concentrated lye tanks and metering pumps . The device also includes a PLC control system, and relies on Metrohm 2035 to build a three-way online automatic cycle inspection and control acid-base concentration analysis device (referred to as online analyzer in the figure).

[0028] The PLC control system has at least six output control terminals and a set of data lines, wherein the output control term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com