Superjunction device and method of making the same

A super-junction device and charge technology, which is applied in the field of semiconductor integrated circuit manufacturing, can solve the problems affecting the device's ability to resist avalanche breakdown, affect the reliability of the device, and weaken the ability, so as to improve the ability to resist avalanche breakdown and improve the collection ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The super junction device of the first embodiment of the present invention:

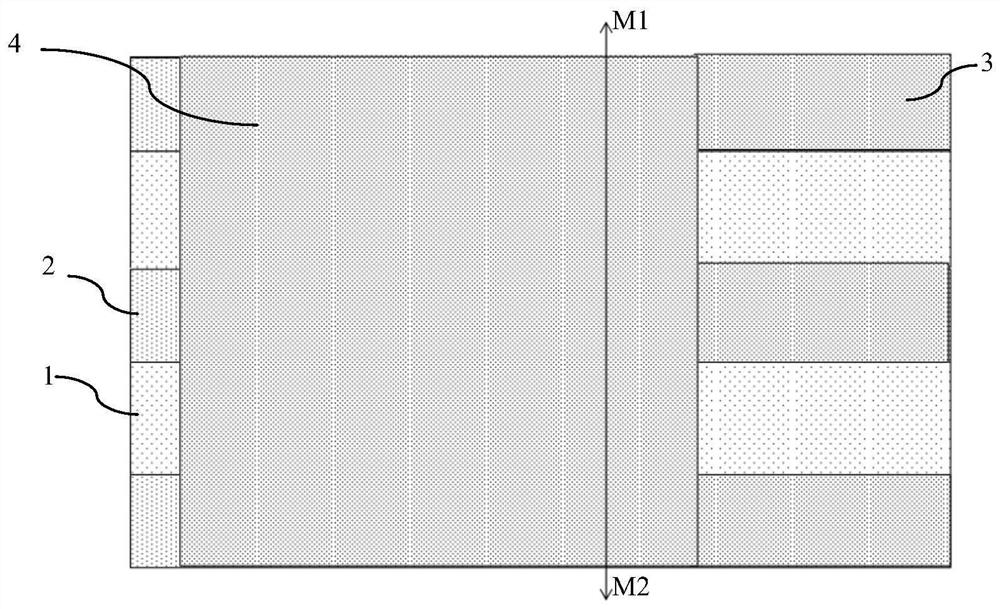

[0070] Such as Image 6 Shown is a top view of the formation area of the source 7a and gate 7b formed by the front metal layer of the superjunction device in the first embodiment of the present invention; in order to more clearly understand the structure of the device in the first embodiment of the present invention, here also combined with Figure 1 to Figure 5 as well as Figure 7 to Figure 10 For explanation, the details are as follows:

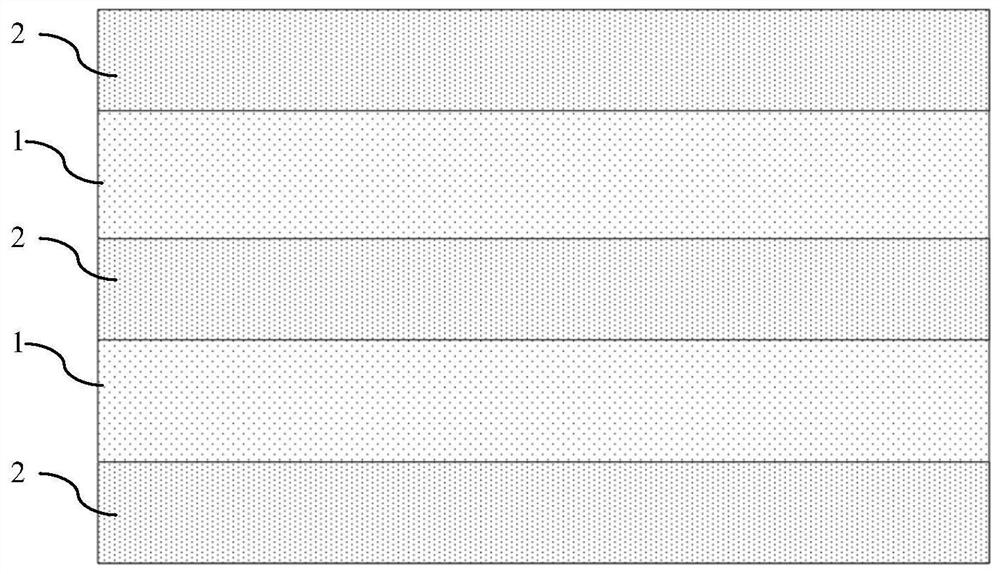

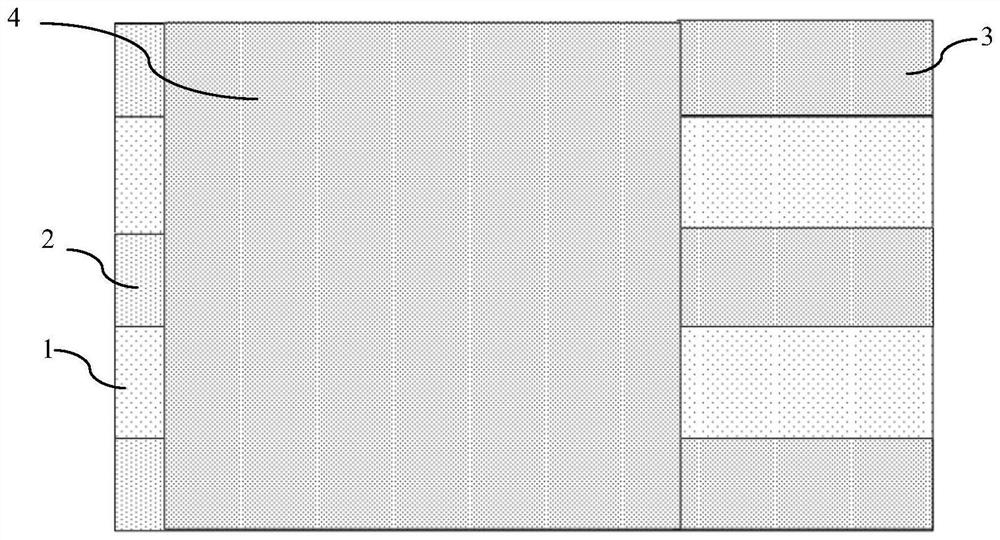

[0071] The super-junction device of the first embodiment of the present invention is described by taking a super-junction MOSFET as an example. The middle region of the super-junction device of the first embodiment of the present invention is the charge flow region, the terminal region surrounds the outer periphery of the charge flow region, and the transition region is located at Between the charge flow region and the termination region; the superjun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com