A preparation method of a lithium sulfide battery cathode material with high vibration density and high volume energy density

A technology of tap density and energy density is applied in the field of preparation of positive electrode materials for lithium-sulfur batteries, which can solve the problems of low volume specific energy of lithium-sulfur batteries, and achieve the effects of convenient transportation, improved tap density and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode 1: This implementation mode records a preparation method of a lithium-sulfur battery positive electrode material with high tap density and high volumetric energy density, and the method is implemented according to the following steps:

[0019] Step 1: First, mix the carbon material and the sublimated sulfur according to the mass ratio of 1:0.5~9, and specifically mix them evenly by means of a ball mill, a grinder, a mixer, a mixer, a mill, etc., to obtain a powdery mixture before heat treatment The ball mill is purchased from Rurui Technology, model is KE-1L; the grinding machine is purchased from TRILOS company, model is TR120A; the mixer is purchased from Shenyang Beiteng Chemical Machinery Company, model is LHY-0.25; the mixer is purchased from Changzhou Zhongshi Sanshui Machinery Technology, the model is AL; the mill is purchased from Changzhou Zhongshi Sanshui Machinery Technology, the model is TCM160;

[0020] Step 2: Fill the powdery ...

specific Embodiment approach 2

[0023] Embodiment 2: A method for preparing a lithium-sulfur battery cathode material with high tap density and high volumetric energy density described in Embodiment 1. In step 1, the carbon material is activated carbon, porous carbon, carbon nanotubes , graphene, doped carbon, Ketjen black, and acetylene black, or one or more of them.

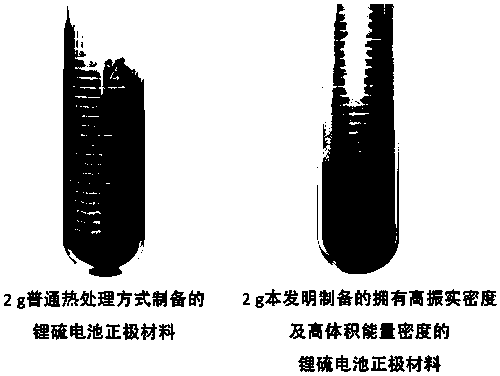

[0024] Table 1 is a statistical data table of electrode density and volume specific capacity of lithium-sulfur battery positive electrode materials prepared by common heat treatment methods and lithium-sulfur battery positive electrode materials prepared by the present invention;

[0025] Table 1

[0026]

Embodiment 1

[0028] (1) First, mix activated carbon and sublimated sulfur at a mass ratio of 1:0.5. The mixture is uniformly mixed by a ball mill to obtain a powdery mixture before heat treatment.

[0029] (2) Fill the powdery mixture before heat treatment obtained in step (1) into a mold, compact it according to a pressure of 1 MPa, and then demould to obtain a block mixture before heat treatment.

[0030] (3) Put the block mixture obtained in step (2) before heat treatment in the reaction vessel at 120 o C, heated for 2 hours until the sulfur melted, and then cooled to room temperature to obtain a heat-treated bulk composite.

[0031] (4) The heat-treated bulk compound obtained in step (3) is crushed under a crusher and passed through a 50-mesh screen to obtain a lithium-sulfur battery cathode material with high tap density and high volumetric energy density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com