Solid electrolyte composition, solid electrolyte-containing sheet, all-solid-state secondary battery, and method for producing solid electrolyte-containing sheet and all-solid-state secondary battery

A solid electrolyte and composition technology, applied in the direction of non-aqueous electrolyte battery electrodes, solid electrolytes, secondary batteries, etc., can solve the problems of reducing battery resistance, achieve excellent dispersion stability, high battery voltage, and excellent ion conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

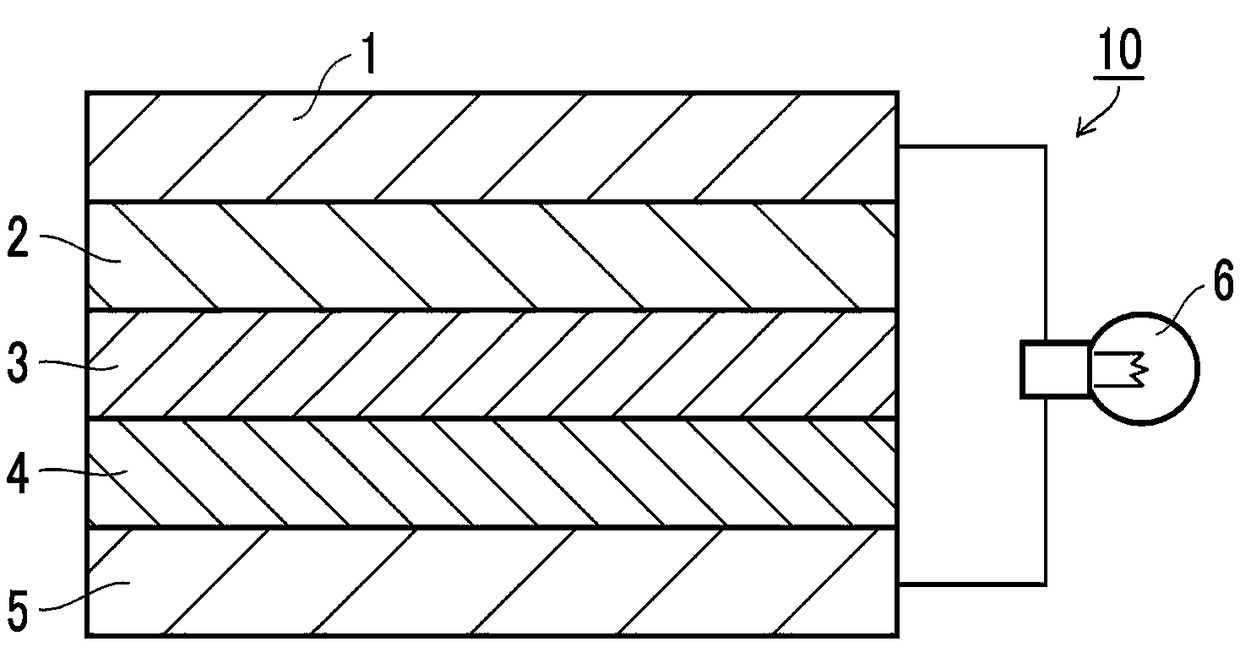

[0208] (Preparation of solid electrolyte composition)

[0209] The solid electrolyte composition of the present invention can be prepared by dispersing the inorganic solid electrolyte (A) and the binder (B) in the presence of the dispersion medium (C) to slurry.

[0210] Slurry can be performed by mixing the inorganic solid electrolyte, binder, and dispersion medium using various mixers. It does not specifically limit as a mixing apparatus, For example, a ball mill, a bead mill, a planetary mixer, a scraper mixer, a roll mill, a kneader, and a disc mill are mentioned. The mixing conditions are not particularly limited. For example, when using a ball mill, mixing is preferably performed at 150 to 700 rpm (rotation per minute) for 1 hour to 24 hours.

[0211] In the case of preparing a solid electrolyte composition containing components such as an active material and a particle dispersant, the addition and mixing may be carried out simultaneously with the dispersion process of ...

Embodiment 1

[0296]

[0297] A dispersion stability test, a viscosity measurement, a volume average particle diameter measurement of an inorganic solid electrolyte in the solid electrolyte composition, and an ion conductivity measurement were performed on the prepared solid electrolyte composition described below. The test and measurement results are summarized in Table 1 below.

[0298] Furthermore, the dispersion stability test and the measurement of the viscosity were performed about the composition for positive electrodes and the composition for negative electrodes prepared below. The test and measurement results are summarized in Tables 2 and 3 below.

[0299] The test method and measurement method are described below.

[0300]

[0301] After preparing each composition described below, it was left to stand at 25° C. in a transparent sample bottle for 24 hours. The state of each composition before and after standing still for 24 hours was observed visually. The solid content of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com