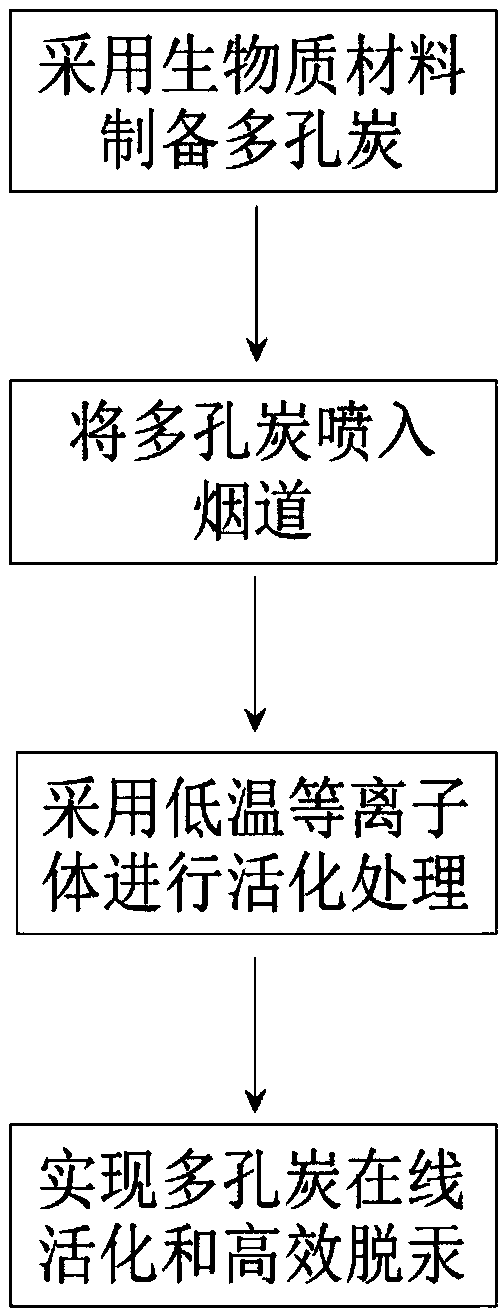

Demercuration method based on on-line activation of porous carbon

A porous carbon and mercury removal technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of high cost of activated carbon injection technology, complex operation process requirements, low mercury adsorption efficiency, etc. The method is simple and reliable, Ease of use and high mercury removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

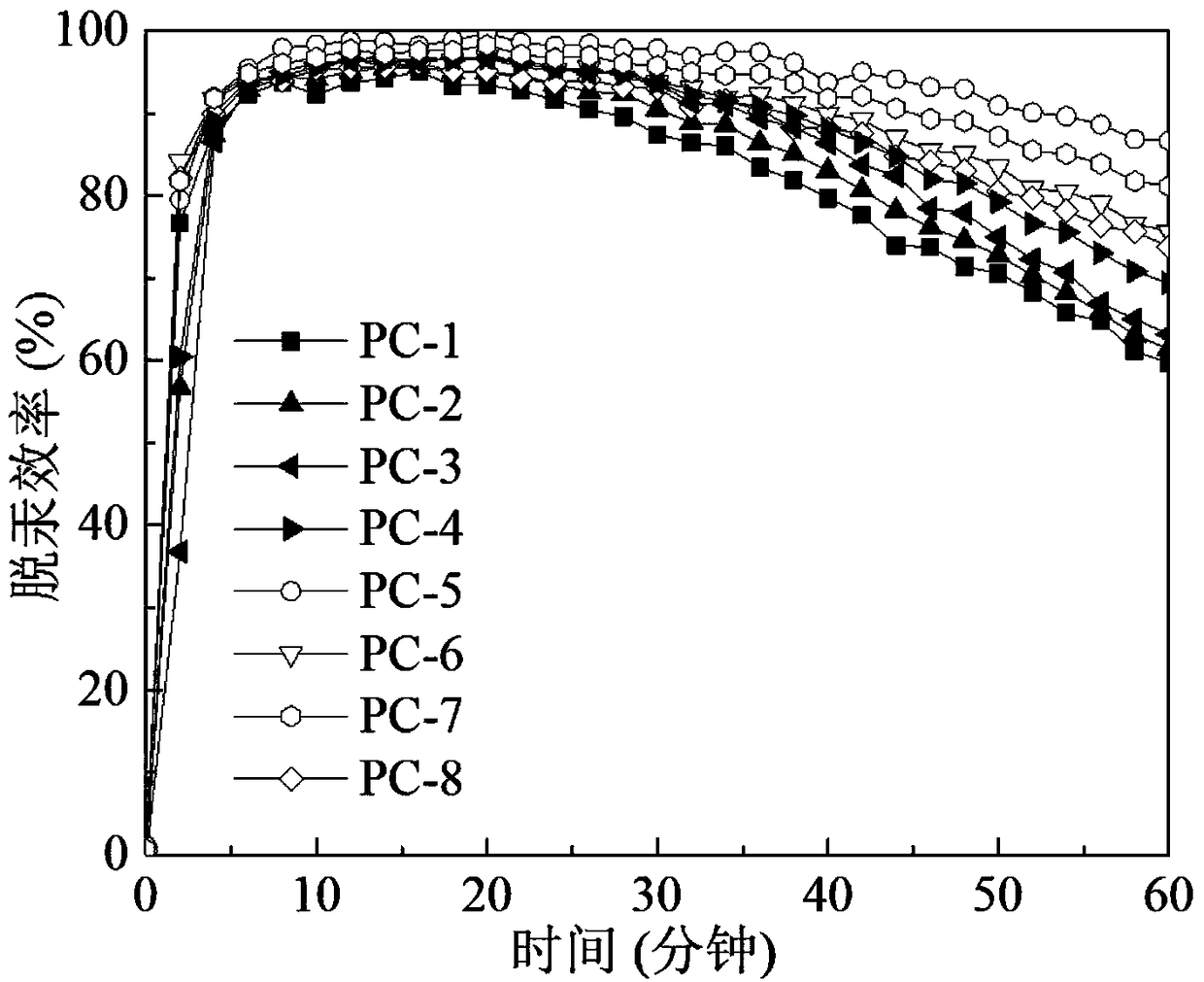

[0037] (1) Perform a hydrothermal reaction of lignin at 180°C for 10 hours to obtain a carbonized precursor; then, carbonize the precursor at 600°C under an inert atmosphere for 0.5 hours to obtain original carbon; then, use it at 900°C CO 2 Carrying out a 2-hour pore expansion activation treatment on the raw carbon to obtain a porous carbon product;

[0038] (2) The obtained porous carbon product is sprayed into the flue, so that the porous carbon and 1% O 2 and 500ppm SO 2 smoke mixture;

[0039] (3) The porous carbon product was treated with low-temperature plasma at 20kV working voltage for 1 second, thereby online activating the porous carbon and simultaneously removing mercury, and the mercury removal efficiency PC-1 was obtained.

Embodiment 2

[0041] (1) Perform a hydrothermal reaction of sucrose at 200°C for 12 hours to obtain a carbonized precursor; then, carbonize the precursor at 600°C for 2 hours under an inert atmosphere to obtain original carbon; then, use CO at 900°C 2 Carrying out a 4-hour pore-expanding activation treatment on the raw carbon to obtain a porous carbon product;

[0042] (2) The obtained porous carbon product is sprayed into the flue, so that the porous carbon and 20% O 2 and 5000ppm SO 2 smoke mixture;

[0043] (3) The porous carbon product was treated with low temperature plasma at 20kV working voltage for 180 seconds, thereby online activating the porous carbon and simultaneously removing mercury to obtain the mercury removal efficiency PC-2.

Embodiment 3

[0045] (1) The starch was subjected to a hydrothermal reaction at 180°C for 10 hours to obtain a carbonized precursor; then, the precursor was carbonized at 550°C for 2 hours under an inert atmosphere to obtain the original carbon; then, at 950°C using CO 2 Carrying out a 2-hour pore expansion activation treatment on the raw carbon to obtain a porous carbon product;

[0046] (2) The obtained porous carbon product is sprayed into the flue, so that the porous carbon and 8% O 2 and 100ppm SO 2 smoke mixture;

[0047] (3) The porous carbon product was treated for 300 seconds with a low-temperature plasma at a working voltage of 60kV, thereby activating the porous carbon online and removing mercury simultaneously, and the mercury removal efficiency PC-3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com