A high-efficiency circulating water cooling device for laser engraving machine

A laser engraving machine and circulating water cooling technology, which is applied in laser welding equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of short contact time between the water tank and cold air, no use of high-temperature gas, and poor water cooling effect, etc., to achieve improvement Engraving effect, improving cooling effect, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

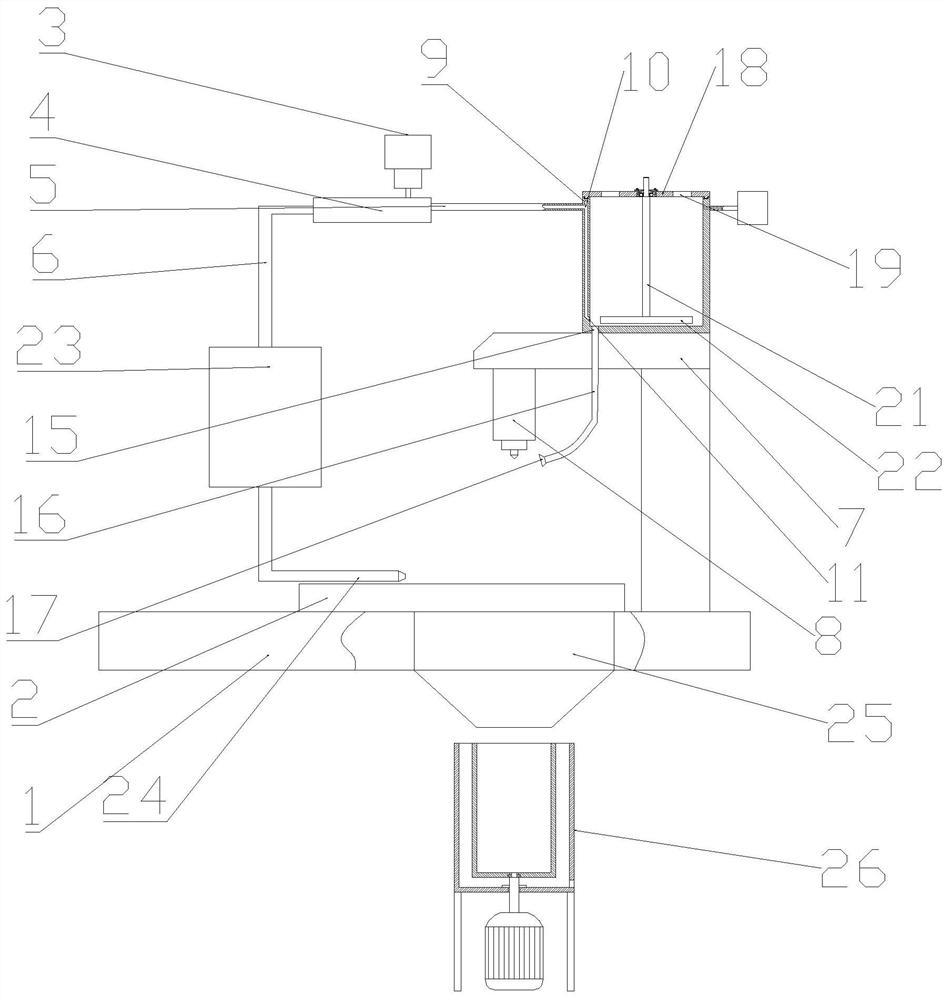

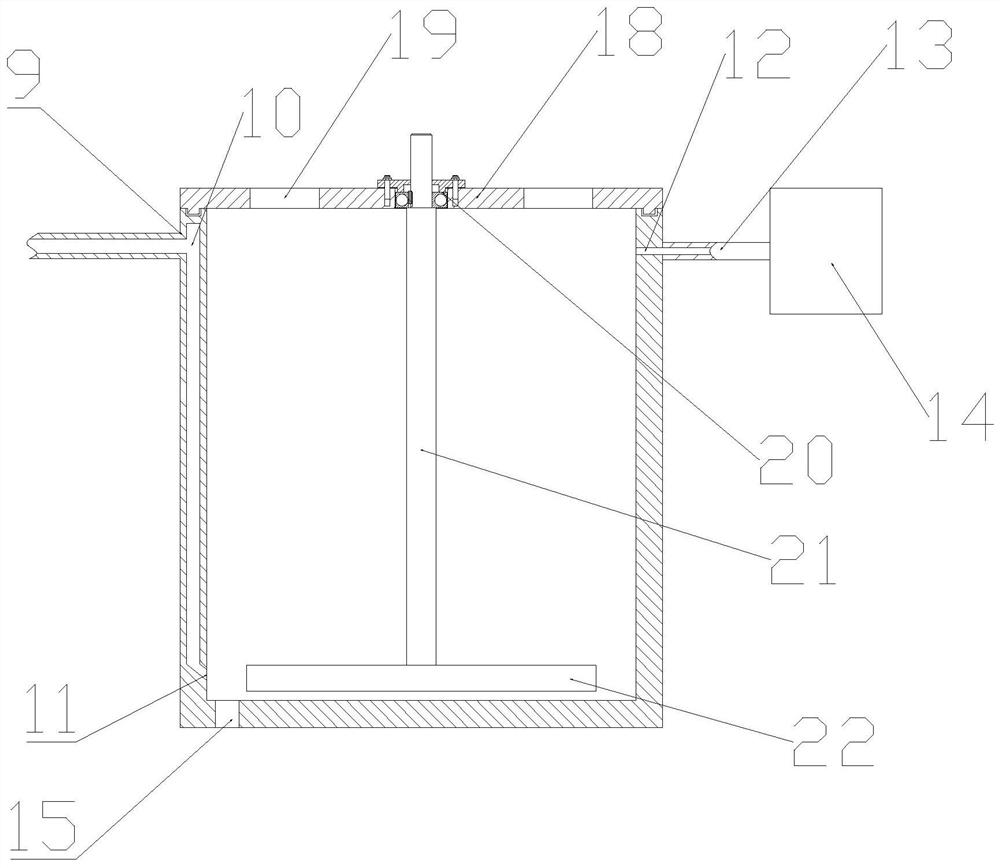

[0017] see figure 1 , figure 2 and image 3 , a high-efficiency circulating water cooling device for a laser engraving machine, comprising a base 1, a workpiece 2, an air compressor 3, a vortex tube 4, a cold air tube 5, a hot air tube 6, a bracket 7 and a laser engraver 8, and the base 1 is placed above There is the workpiece 2, the air compressor 3 is arranged above the workpiece 2, the air compressor 3 communicates with the air inlet of the vortex tube 4, and the cold wind is arranged on the right side of the vortex tube 4 Pipe 5, the hot air pipe 6 is arranged on the left side of the vortex pipe 4, the laser engraver 8 is installed on the bolt below the bracket 7; the right side of the cold air pipe 5 communicates with the cold air inlet 10, and the cold air The inlet 10 is set on the inner wall on the left side of the cooling box 9. The cold air inlet 10 and the bottom of the inner cavity of the cooling box 9 form a cold air outlet 11. Cold air can enter from the cold ...

Embodiment 2

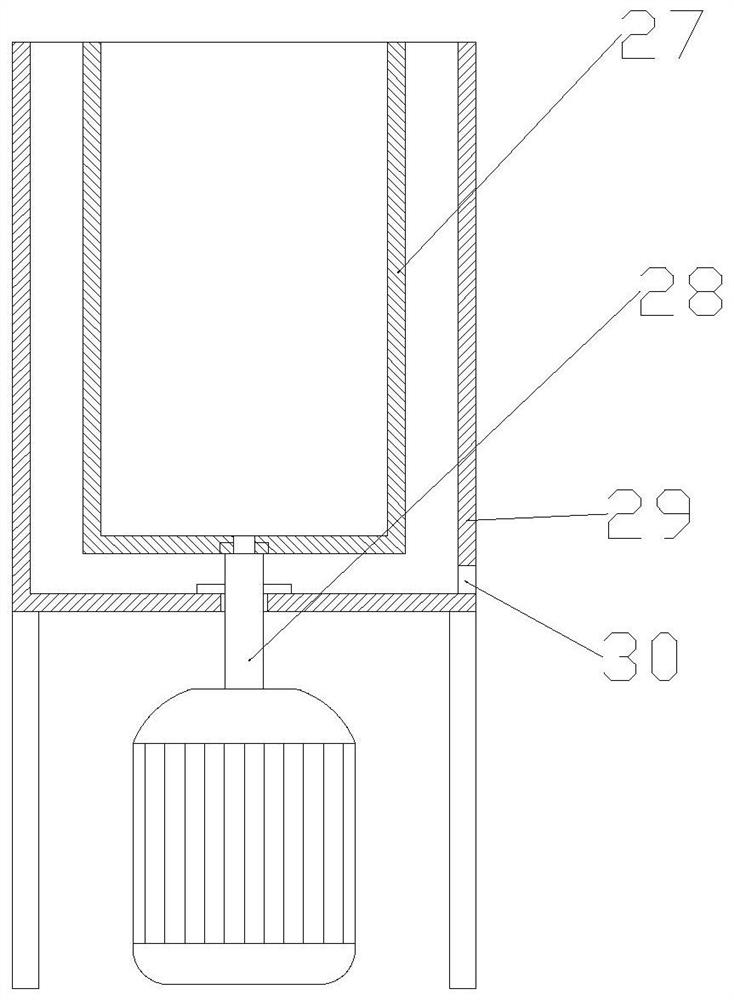

[0019] see Figure 4 Compared with Embodiment 1, this embodiment 2 is only different in that the number of the waste liquid recovery device 26 is greater than one, and another waste liquid recovery device 26 can be replaced to continue filtering after the iron filings in the screen frame 27 are filled. , to facilitate continuous operation.

[0020] The working principle of the present invention is: cold air can enter from described cold air inlet 10, blow out from described cold air outlet 11, be used for cooling the water in described cooling box 9, reach the effect of lowering water temperature; Described cold air outlet 11 places water temperature Lowest, it can directly flow from the water outlet 15 into the cooling pipe 16 for the cooling of the laser engraver 8, making full use of the cooling effect of the cold air, greatly improving the cooling of the laser engraver 8 Effect: the stirring blade 22 is welded and fixed at the bottom of the stirring shaft 21, and the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com