A method for preparing rhenium pentachloride

A rhenium pentachloride and chlorine gas technology, applied in chemical instruments and methods, rhenium compounds, inorganic chemistry, etc., can solve problems such as low purity, potential safety hazards of chlorine gas, and no devices and methods for rhenium pentachloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

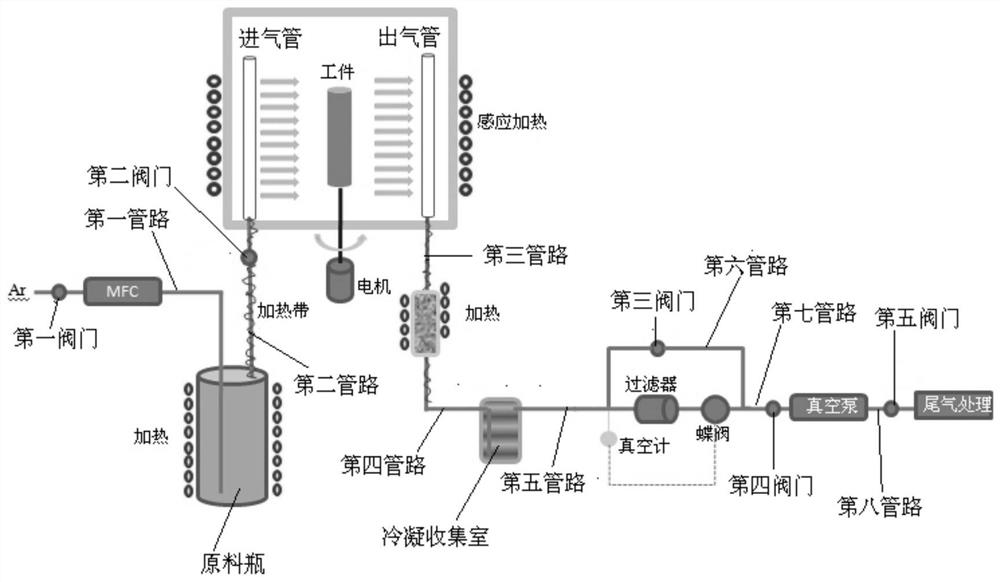

[0072] The invention proposes a high-purity metal chloride preparation device, which adopts the method of high-temperature direct chlorination of metal powder to obtain high-purity metal chloride. The device includes a chlorine gas input system, an inert gas input system, a metal chlorination reaction system, a chloride purification system, a chloride collection bottle, a vacuum system, and a control cabinet. Among them, the metal chlorination reaction system can be independently heated and kept at a certain temperature range during the chlorination process; the chloride purification system can be independently heated and kept at a certain temperature range during the sublimation and purification process; the chloride collection bottle adopts circulating water During the chlorination process, the input amount of chlorine gas is controlled by adjusting the chlorine gas pressure reducing valve to make the air bag expand moderately; the vacuum pump is protected by a liquid nitroge...

Embodiment 1

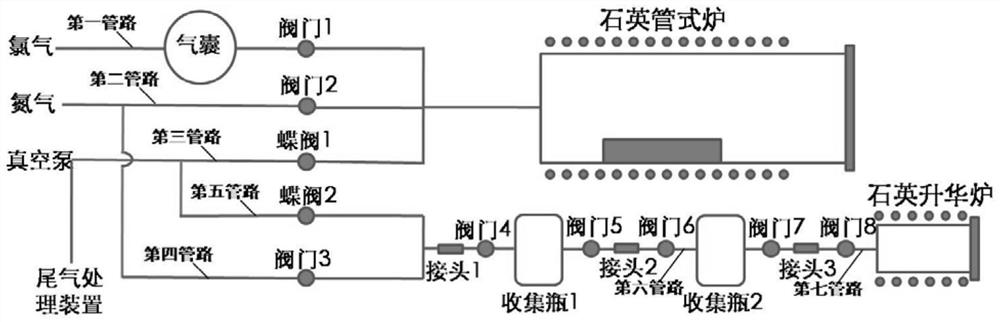

[0097] like figure 1 As shown, a device for preparing rhenium pentachloride, the device includes a nitrogen gas cylinder, a chlorine gas cylinder, a vacuum pump, an exhaust gas treatment device, a quartz tube furnace, a quartz sublimation furnace, a collection bottle 1 and a collection bottle 2;

[0098] Storing nitrogen in the nitrogen cylinder;

[0099] Store chlorine in the described chlorine cylinder;

[0100] The collection bottle 1 and the collection bottle 2 are cooled by circulating water;

[0101] Metal rhenium powder is placed in the quartz tube furnace, 3 / 4 of the length of the quartz tube in the quartz tube furnace is placed in the resistance furnace, 1 / 4 of the length is placed outside the resistance furnace, and the quartz tube is energized through the resistance furnace for heating;

[0102] The quartz sublimation furnace is heated by electric resistance;

[0103] The tail gas treatment device is used to process unreacted chlorine, and the treatment method a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thrust | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com