High-strength water-permeable concrete and its preparation method

A water-permeable and concrete technology, applied in the field of concrete, can solve the problems of the contradiction between strength and water-permeability, poor work performance, restrict the use of permeable concrete, etc., and achieve the effect of improving drainage effect, improving strength and prolonging durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

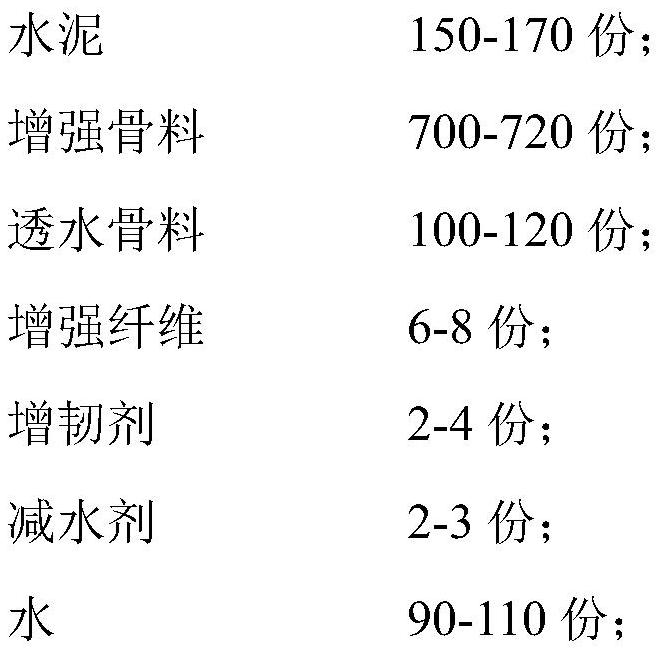

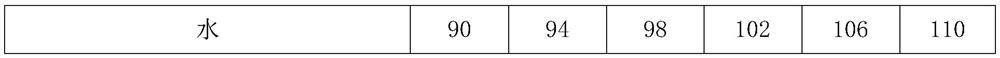

Method used

Image

Examples

preparation example 1

[0059] Preparation Example 1: Stir 0.5kg of benzoic acid, 1kg of ethylene glycol monobutyl ether, 2kg of sodium lignosulfonate and 2kg of sodium silicate at a speed of 400r / min, then add 2kg of redispersible latex powder, 6kg of high Molecular porous microspheres were stirred at a speed of 1000 r / min for 30 minutes at a temperature of 110° C. to obtain a toughening agent.

preparation example 2

[0060] Preparation example 2: Stir 0.8kg benzoic acid, 1.5kg ethylene glycol monobutyl ether, 2.5kg sodium lignosulfonate and 2.5kg sodium silicate at a speed of 500r / min, then add 2.5kg redispersible latex powder, 8 kg of polymer porous microspheres, and stirred at a speed of 1100 r / min for 25 min at a temperature of 115° C. to obtain a toughening agent.

preparation example 3

[0061] Preparation Example 3: Stir 1kg of benzoic acid, 2kg of ethylene glycol monobutyl ether, 3kg of sodium lignosulfonate and 3kg of sodium silicate evenly at a speed of 600r / min, then add 3kg of redispersible latex powder, 10kg of polymer Porous microspheres were stirred at a speed of 1200 r / min for 20 min at a temperature of 120° C. to obtain a toughening agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com