Method of extracting polysaccharide from pitaya pericarp

A technology of pitaya peel and polysaccharide, which is applied in the field of extracting polysaccharide from pitaya peel, can solve the problems of low polysaccharide yield and the like, and achieves the effects of simple operation, reduced pollution and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

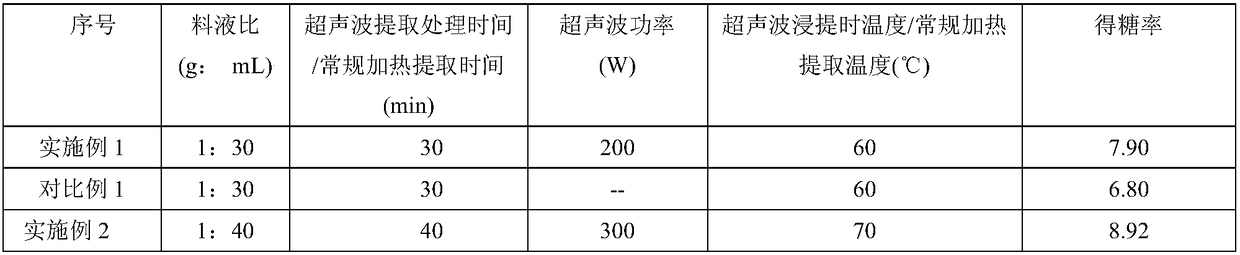

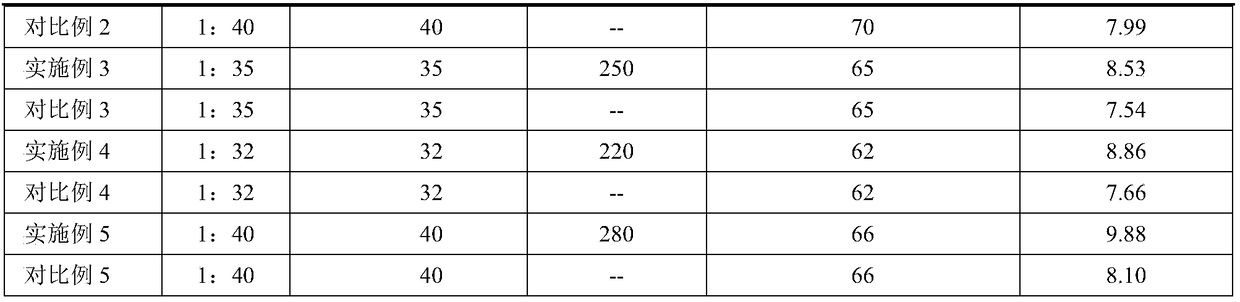

Embodiment 1

[0037] (1) Raw material processing: Take 1 kg of pitaya peel, wash it, slice it, place it in a drying box, and dry it at a temperature of 50 ° C. Take out the dried pitaya peel, then mechanically crush it, and use an 80-mesh standard Sieve and sieve, collect the powder after sieving to get dragon fruit peel powder;

[0038] (2) Ultrasonic extraction: mix dragon fruit peel powder with water according to the ratio of 1g to 30mL and pour it into a container, shake well and place it in an ultrasonic instrument for extraction treatment for 30min. The ultrasonic power is 200W and the temperature is 60°C. Repeat the operation of ultrasonic leaching for 3 times, and then use it at a centrifugal speed of 6000 rpm for 15 minutes to collect the centrifuged liquid to obtain an extract;

[0039] (3) Ultrafiltration membrane cut-off concentration: the extract prepared above was separated with an ultrafiltration membrane (10000), and the extract in the membrane was collected, and the extract...

Embodiment 2

[0042] (1) Raw material processing: take 1 kg of pitaya peel, wash it, slice it, place it in a drying box, and dry it at a temperature of 60°C, take out the dried pitaya peel, and then mechanically crush it, using a 100-mesh standard Sieve and sieve, collect the powder after sieving to get dragon fruit peel powder;

[0043] (2) Ultrasonic extraction: mix dragon fruit peel powder with water according to the ratio of 1g to 40mL and pour it into a container, shake well and place it in an ultrasonic instrument for extraction treatment for 40min. The ultrasonic power is 300W and the temperature is 70°C. Repeat the operation of ultrasonic leaching for 5 times, and then use it at a centrifugal speed of 7000 rpm for 30 minutes to collect the centrifuged liquid to obtain an extract;

[0044] (3) Ultrafiltration membrane cut-off concentration: the extract prepared above was separated with an ultrafiltration membrane (15000D), and the extract in the membrane was collected, and the extrac...

Embodiment 3

[0047] (1) Raw material processing: Take 2kg of pitaya peel, wash it, slice it, place it in a drying box, and dry it at a temperature of 55°C. Take out the dried pitaya peel, then mechanically crush it, and use a 90-mesh standard Sieve and sieve, collect the powder after sieving to get dragon fruit peel powder;

[0048] (2) Ultrasonic extraction: mix dragon fruit peel powder with water according to the ratio of 1g to 35mL and pour it into a container, shake well and place it in an ultrasonic instrument for extraction treatment for 35min. The ultrasonic power is 250W and the temperature is 65°C. Repeat the operation of ultrasonic leaching 4 times, and then use it at a centrifugal speed of 6500 rpm for 20 minutes to collect the centrifuged liquid to obtain an extract;

[0049] (3) Ultrafiltration membrane cut-off concentration: the extract prepared above was separated with an ultrafiltration membrane (12000D), the leachate in the membrane was collected, and the leachate was conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com