Waterborne double-component wood coating

A wood coating, two-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the hardness and scratch resistance of the paint film, the chemical resistance is not high, the degree of cross-linking is not dense enough, and the film is formed. The quality of the product is not guaranteed, and the effect of high hardness, good water resistance and simple production process is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

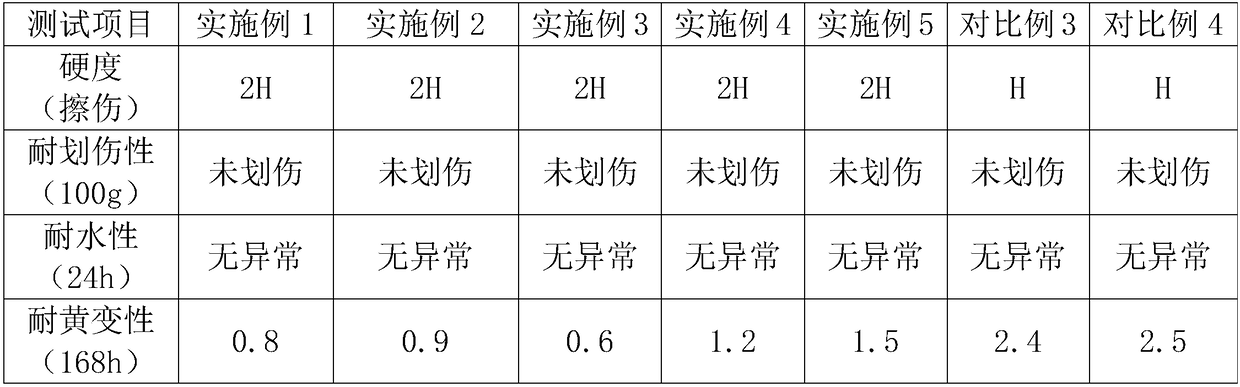

Examples

Embodiment 1

[0020] The water-based two-component wood coating is prepared from two parts, the main agent and the curing agent, and the mass ratio of the main agent to the curing agent is 1:1.5.

[0021] The main agent includes the following components: 50% acrylic emulsion, 23% water-based polyurethane dispersion, 4% film-forming aid, 1.2% wetting agent, 0.8% leveling agent, 1.6% defoamer, 1.5% wax, 0.6% preservative, 2.3% ultraviolet absorber, and 15% water; wherein the ultraviolet absorber is a mixture of benzophenone:aromatic β-diketone, and its mass ratio is 1:1.3.

[0022] By mass percentage, the curing agent includes the following components: 40% propylene glycol diacetate and 60% cyanate mixture; the cyanate mixture is a mixture of water-based isocyanate and hydrogenated xylylene diisocyanate, which The mass ratio is 1.5:1.

[0023] Prepare as follows:

[0024] (1) Preparation of main ingredient: Stir acrylic emulsion and water-based polyurethane dispersion at high speed, then ad...

Embodiment 2

[0028] The water-based two-component wood coating is prepared from two parts, the main agent and the curing agent, and the mass ratio of the main agent to the curing agent is 1:1.8.

[0029] By mass percentage, the main agent includes the following components: 70% acrylic emulsion, 14% water-based polyurethane dispersion, 1.7% film-forming aid, 0.2% wetting agent, 0.1% leveling agent, 0.5% defoamer, 0.5% wax, 0.2% preservative, 1% benzophenone, 1.8% aromatic β-diketone and 10% water; wherein the UV absorber is a mixture of benzophenone: aromatic β-diketone, the mass ratio of which is 1:1.8.

[0030] By mass percentage, the curing agent includes the following components: 20% propylene glycol diacetate and 80% cyanate mixture; the cyanate mixture is a mixture of water-based isocyanate and hydrogenated xylylene diisocyanate, which The mass ratio is 2.5:1.

[0031] Prepare as follows:

[0032] (1) Preparation of main ingredient: Stir acrylic emulsion and water-based polyurethan...

Embodiment 3

[0036] The water-based two-component wood coating is prepared from two parts, the main agent and the curing agent, and the mass ratio of the main agent to the curing agent is 1:1.6.

[0037] According to the following mass percentage composition: the main agent includes the following components: 60% acrylic emulsion, 20% water-based polyurethane dispersion, 2.5% film-forming aid, 0.5% wetting agent, 0.5% leveling agent, 1% Antifoaming agent, 1% wax, 0.4% preservative, 2.1% UV absorber and 12% water; wherein the UV absorber is a mixture of benzophenone:aromatic β-diketone, and its mass ratio is 1:1.8.

[0038] By mass percentage, the curing agent includes the following components: 30% propylene glycol diacetate and 70% cyanate mixture; the cyanate mixture is a mixture of water-based isocyanate and hydrogenated xylylene diisocyanate, which The mass ratio is 2:1.

[0039] Prepare as follows:

[0040] (1) Preparation of main ingredient: Stir acrylic emulsion and water-based poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com