Bipolar membrane taking porous anode membrane as base material and preparation method of bipolar membrane

A technology of bipolar membranes and porous base membranes, applied in diaphragms, organic diaphragms, electrolysis processes, etc., can solve problems such as interpenetration, lower production efficiency of bipolar membranes, and increased water dissociation voltage of composite bipolar membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention provides a method for preparing a bipolar membrane based on a porous positive membrane as described in the technical solution, comprising the following steps:

[0043] a) dissolving the cyano polymer in an organic solvent, scraping the obtained film solution, and obtaining a porous base film layer containing a cyano functional group in water by phase separation; oxidizing the cyano group in the porous base film layer to a carboxyl group to obtain Porous cation exchange membrane layer;

[0044] b) Soak the cation exchange membrane layer in the intermediate layer solution containing the metal ion-amine complex, take it out and place it on the substrate, and dry it to obtain the cation exchange membrane layer with the intermediate interface layer;

[0045] c) casting the anion-exchange membrane liquid onto the middle interface layer of the cation-exchange membrane layer with the middle interface layer, and drying to obtain a bipolar membrane with a po...

Embodiment 1

[0060] 1. Preparation method of bipolar membrane

[0061] 1.1 Prepare a polyacrylonitrile film solution with a mass concentration of 17%, pour an appropriate amount of film solution on a smooth and clean glass plate, and use an automatic film scraper to scrape the film. The glass plate is quickly placed in a container of water, causing as little fluctuation as possible in the water surface. As the organic solvent N,N-dimethylformamide gradually dissolves into water, polyacrylonitrile forms a uniform film layer on the glass plate, and the prepared finger-shaped pore-based film layer is placed in pure water, and then the for hydrolysis reactions.

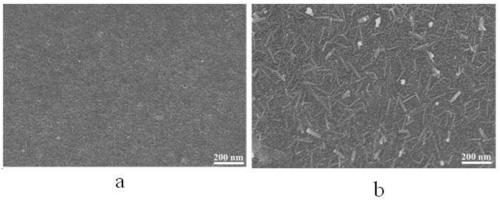

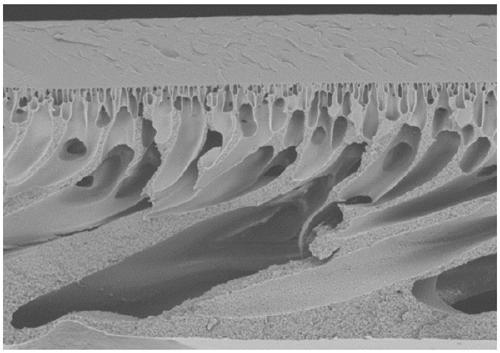

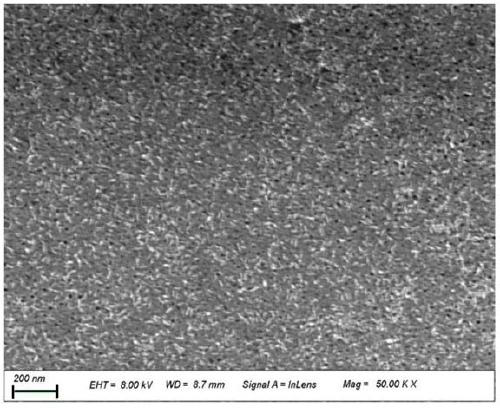

[0062] 1.2 Put the above-mentioned base film layer into 1.5mol / L sodium hydroxide, and react in an oven at 60°C for 2 hours. The porous membrane layer was taken out, washed three times with pure water, then soaked in 1mol / L hydrochloric acid for 12 hours, then taken out, washed three times with pure water. Scanning electron microsc...

Embodiment 2

[0092] 2.1 Prepare a polyacrylonitrile film solution with a mass concentration of 20%, pour an appropriate amount of film solution on a smooth and clean glass plate, and use an automatic film scraper to scrape the film. Put the glass plate into a container filled with water, put the prepared porous base membrane layer into pure water, and then use it for hydrolysis reaction.

[0093] 2.2 Put the above-mentioned base film layer into 2mol / L sodium hydroxide, and react in an oven at 40°C for 2 hours. The porous film layer was taken out, washed three times with pure water, then the film was soaked in 2mol / L hydrochloric acid for 12 hours, then the film layer was taken out, washed three times with pure water.

[0094] 2.3 Prepare a mixed solution of 1,3-propylenediamine and cobalt chloride with a mass ratio of 1:5, dissolve 1g of 1,3-propylenediamine and 5g of cobalt chloride in pure water, and dilute to a 1000mL volumetric flask , the solution was stirred at room temperature for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com