Bipolar membrane and preparation method thereof

A bipolar membrane, membrane liquid technology, applied in the direction of diaphragm, electrolysis process, electrolysis components, etc., can solve the problems of high voltage drop of bipolar membrane, high voltage on both sides of the membrane, small particle size, etc., to reduce the water dissociation voltage, The effect of improving water dissociation performance and promoting water dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

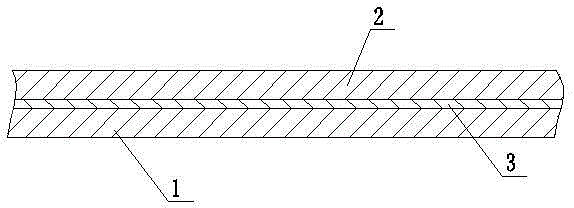

Image

Examples

Embodiment 1

[0024] (1) Preparation of the membrane solution of the intermediate interface layer

[0025] Dissolve 2 millimoles of polyvinyl alcohol in water to make a polyvinyl alcohol aqueous solution with a concentration of 2 mmol / L, then add 20 millimoles of ferric chloride to the polyvinyl alcohol aqueous solution, and stir evenly to obtain an intermediate interface layer film solution .

[0026] (2) Preparation of bipolar membrane

[0027] Take a piece of anion exchange membrane [the membrane is manufactured by Shandong Tianwei Membrane Technology Co., Ltd., the thickness of the membrane is 0.155 mm, the thickness change rate is 4.85%, the water content is 26.56%, the ion exchange capacity (dry) is 1.8 mmol / g, and the surface resistance is 3.91 Ω·cm 2 , migration number 0.976, differential pressure osmotic migration coefficient 21.9ml / (hr-m 2 -bar)] on the surface of the anion-exchange membrane, evenly coat one layer of intermediate interface layer membrane solution, then place it...

Embodiment 2

[0032] (1) Preparation of the membrane solution of the intermediate interface layer

[0033] Dissolve 0.5 mmol polyvinyl alcohol in water to make a polyvinyl alcohol aqueous solution with a concentration of 0.5 mmol / L, then add 20 mmol ferric chloride into the polyvinyl alcohol aqueous solution, and stir evenly to obtain an intermediate interface layer film liquid.

[0034] (2) Preparation of bipolar membrane

[0035] Take a piece of anion exchange membrane [the membrane is manufactured by Shandong Tianwei Membrane Technology Co., Ltd., the thickness of the membrane is 0.155 mm, the thickness change rate is 4.85%, the water content is 26.56%, the ion exchange capacity (dry) is 1.8 mmol / g, and the surface resistance is 3.91 Ω·cm 2 , migration number 0.976, differential pressure osmotic migration coefficient 21.9ml / (hr-m 2 -bar)] on the surface of the anion-exchange membrane, evenly coat one layer of intermediate interface layer membrane solution, then place it in an oven and...

Embodiment 3

[0040] (1) Preparation of the membrane solution of the intermediate interface layer

[0041] Dissolve 5 millimoles of polyvinyl alcohol in water to make a polyvinyl alcohol aqueous solution with a concentration of 5 mmol / L, then add 150 millimoles of ferric chloride into the polyvinyl alcohol aqueous solution, and stir evenly to obtain an intermediate interface layer film solution .

[0042] (2) Preparation of bipolar membrane

[0043] Take a piece of anion exchange membrane [the membrane is manufactured by Shandong Tianwei Membrane Technology Co., Ltd., the thickness of the membrane is 0.155 mm, the thickness change rate is 4.85%, the water content is 26.56%, the ion exchange capacity (dry) is 1.8 mmol / g, and the surface resistance is 3.91 Ω·cm 2 , migration number 0.976, differential pressure osmotic migration coefficient 21.9ml / (hr-m 2 -bar)] on the surface of the anion-exchange membrane, evenly coat one layer of intermediate interface layer membrane solution, then place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com