Nano conductive paper, preparation method of nano conductive paper and capacitor

A nano-conductive and conductive material technology, applied in fixed capacitor electrodes, nanotechnology, nanotechnology, etc., can solve the problems of limited application of paper-based flexible conductive materials, poor mechanical properties, opacity, etc., to achieve good conductivity and low Young's. Modulus, high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a preparation method of nano conductive paper, comprising:

[0039] Mix the nano cellulose and the conductive material evenly and then vacuum filter to obtain the nano conductive film;

[0040] The nano conductive film is soaked in the mixed aqueous solution of choline chloride and urea, and then taken out and dried.

[0041] Preferably, the nanocellulose is obtained by oxidizing and homogenizing hardwood pulp, eucalyptus pulp or softwood pulp through a TEMPO / NaBr / NaClO system.

[0042]It should be noted that TEMPO (2,2,6,6-tetramethylpiperidine-1-oxyl radical) is a water-soluble piperidine-like nitroxide radical. The TEMPO / NaBr / NaClO system is a new type of selective oxidation system, TEMPO and NaBr are used as catalysts, and NaClO is used as an oxidant. The TEMPO / NaBr / NaClO system can effectively introduce aldehyde groups and carboxyl groups to the cellulose surface in a liquid phase environment with a pH of 10-11, and oxidize the C6 hydroxyl ...

Embodiment 1

[0061] (1) Preparation of transparent substrate nanocellulose: soak the hardwood pulp board in deionized water and then stir the obtained slurry through TEMPO / NaBr / NaClO system for oxidation treatment, and then homogenize to obtain nanocellulose .

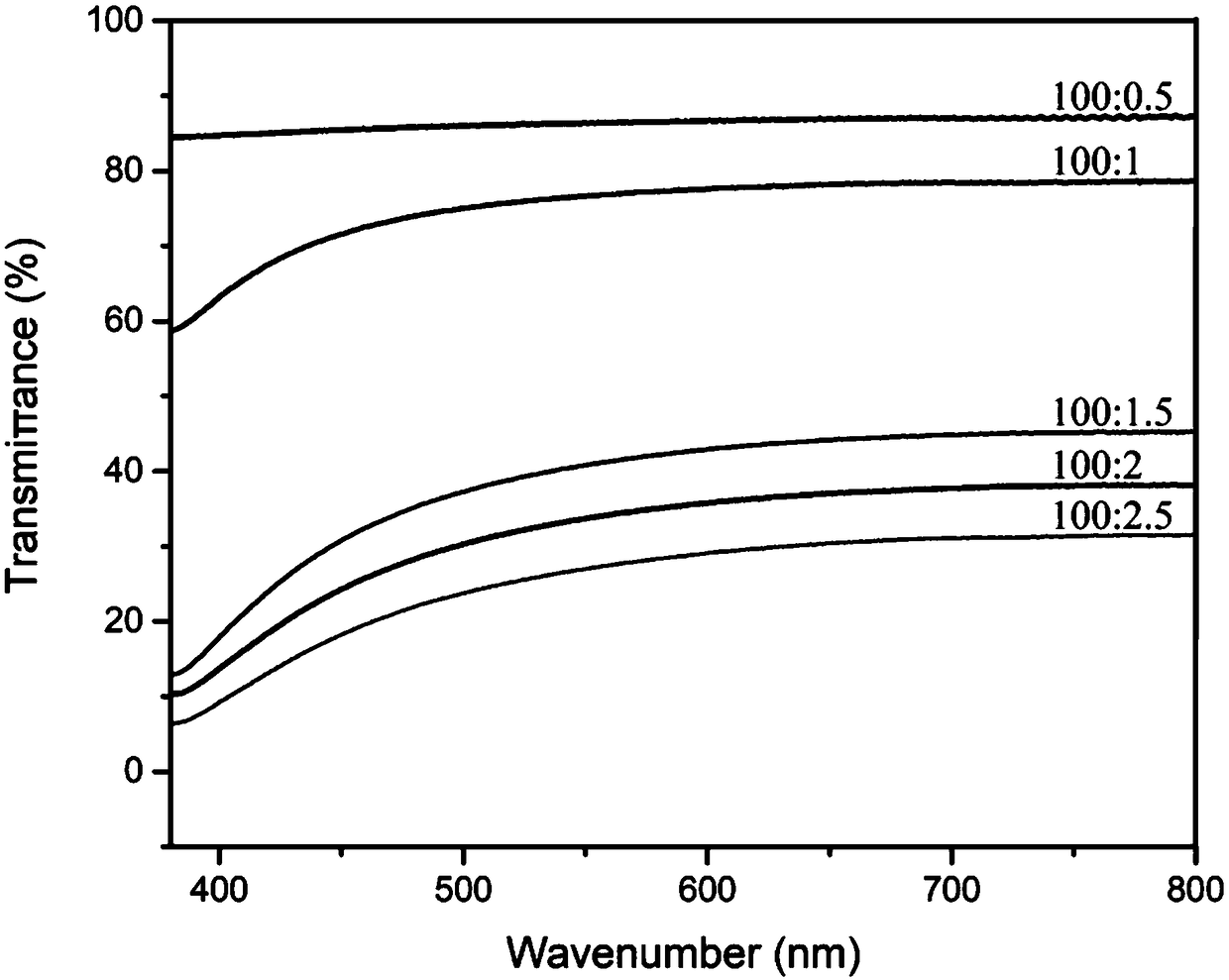

[0062] (2) Preparation of a conductive mixture: the nanocellulose prepared in step (1) was mixed with the nanosilver wire at a mass ratio of 100:0.5, and ultrasonically oscillated for 30 minutes to mix them uniformly to obtain a conductive mixture.

[0063] (3) Preparation of nano-conductive film: take the conductive mixture prepared in step (2), and vacuum filter to obtain the nano-conductive film.

[0064] (4) Preparation of nano-conductive paper: Take the nano-conductive film prepared in step (3) and immerse it in the choline chloride / urea aqueous solution. After soaking for 12 hours, take it out and clamp it with a glass plate and place it in an oven at 80°C for 3 hours to obtain the nano-conductive film. Conductive paper; whe...

Embodiment 2

[0066] (1) Preparation of transparent substrate nanocellulose: soak the hardwood pulp board in deionized water and then stir the obtained slurry through TEMPO / NaBr / NaClO system for oxidation treatment, and then homogenize to obtain nanocellulose .

[0067] (2) Preparation of a conductive mixture: the nanocellulose prepared in step (1) was mixed with the nanosilver wire at a mass ratio of 100:1, and ultrasonically oscillated for 30 minutes to mix them evenly to obtain a conductive mixture.

[0068] (3) Preparation of nano-conductive film: take the conductive mixture prepared in step (2), and vacuum filter to obtain the nano-conductive film.

[0069] (4) Preparation of nano-conductive paper: take the nano-conductive film prepared in step (3) and immerse it in the choline chloride / urea aqueous solution, after soaking for 12 hours, take it out and clamp it with a glass plate and place it in an oven at 90°C to dry for 2.5 hours to obtain Nano conductive paper; wherein, in the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com