Ku-band dual-polarization radiometer antenna feeder

An antenna feed, dual-polarization technology, used in antennas, waveguide horns, waveguide devices, etc., can solve the problems of excessive metal material density, long manufacturing cycle, and heavy processing device weight, and achieve low 3D printing cost, Good for mass production and good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

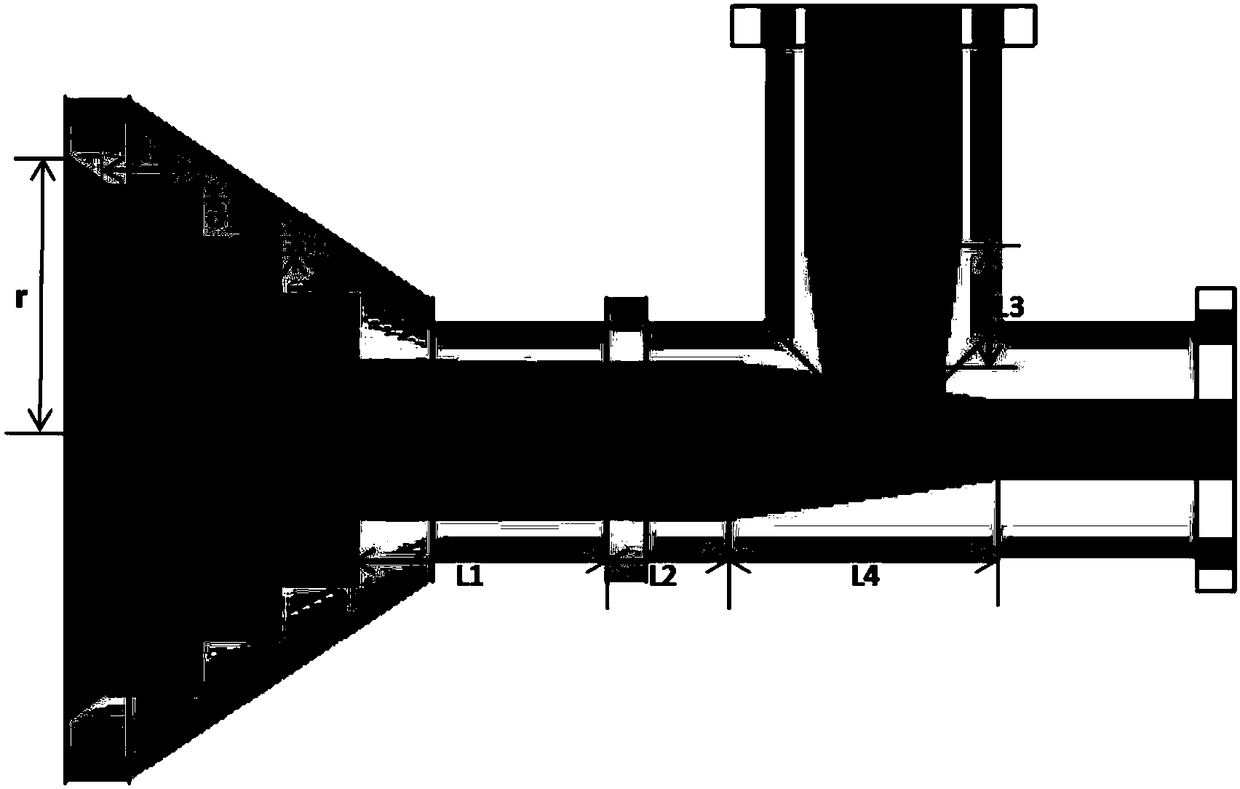

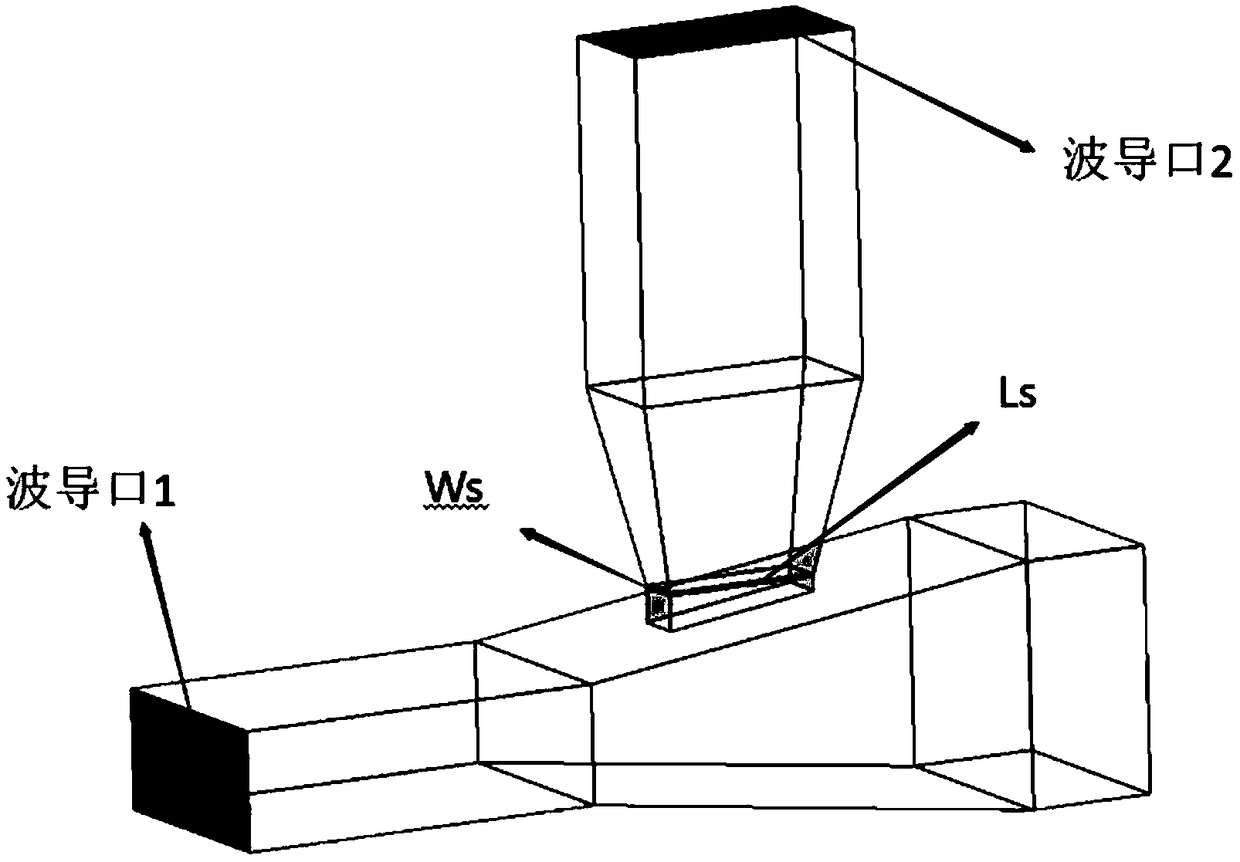

[0034] Such as figure 1 As shown, in this embodiment, the opening angle θ=35o; horn radius R=35.3mm; groove wall thickness d=4.9mm; groove wall spacing m=2mm; groove depth h=12.28mm; square-circle converter length L1=22mm ; The length of the square waveguide L2 = 10.2mm; the length of the pyramid connected with the square waveguide L4 = 37mm; the length of the other pyramid L3 = 24.6mm. Such as figure 2 As shown, in this example, the length Ls=12.5mm and the width Ws=3.9mm of the rectangular opening where the two pyramids intersect. The dimensions of the square waveguide, rectangular waveguide, and circular waveguide ports are those of the Ku-band standard waveguide.

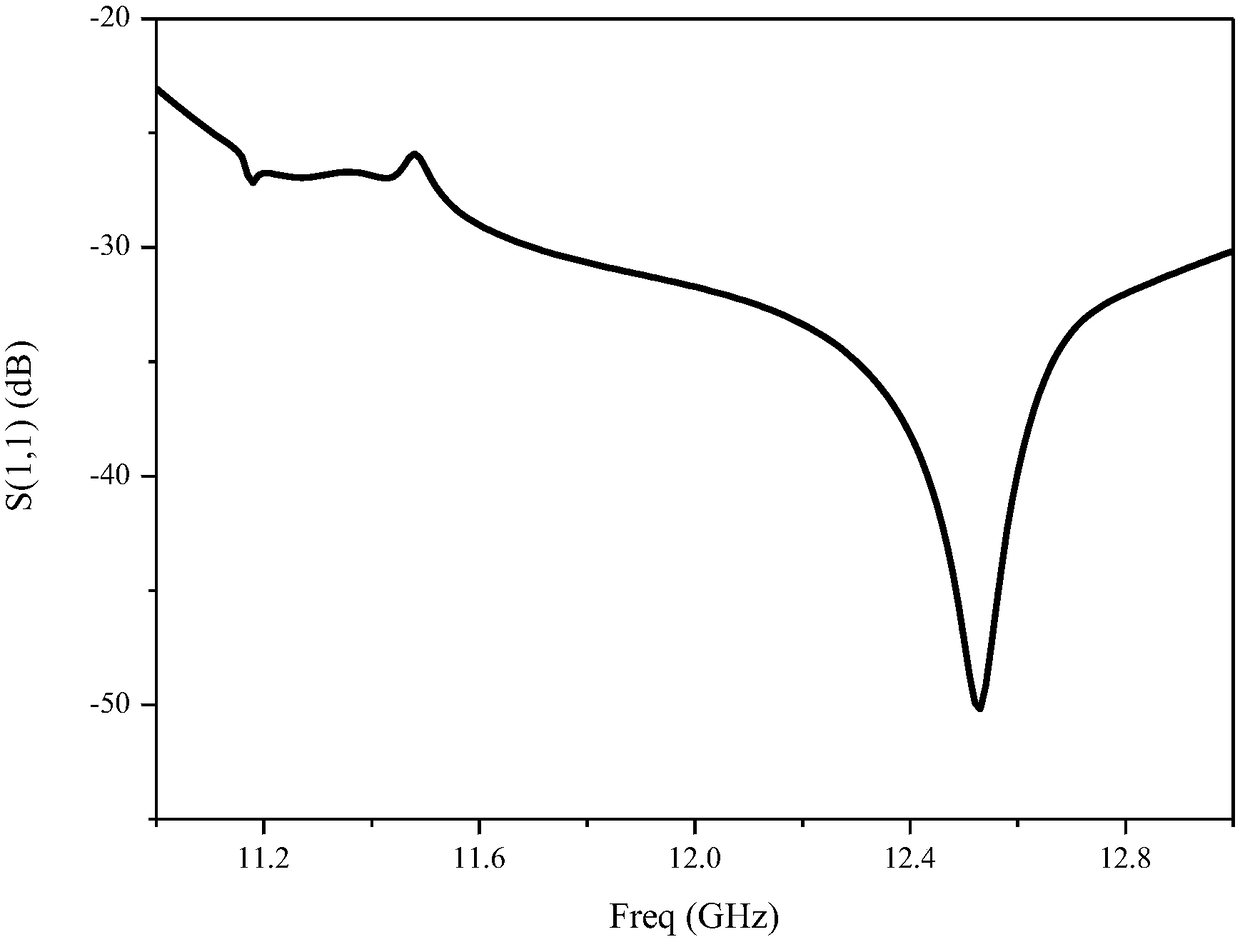

[0035] By simulating the front-end with HFSS software, the return loss of waveguide port 1 can be obtained as follows: image 3 As shown, the return loss of waveguide port 2 is as Figure 4 As shown, the return loss of the two ports in the front-end working frequency band is less than -10dB, S11 is less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com