Intelligent factory seedling base

A factory-like and intelligent technology, applied in climate change adaptation, horticulture, greenhouse cultivation, etc., can solve the problems of complex time and space changes of environmental elements, lack of optimized software for control systems, and high operating costs, so as to shorten the seedling breeding cycle , Improve the survival rate of seedlings, reduce the effect of personnel demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

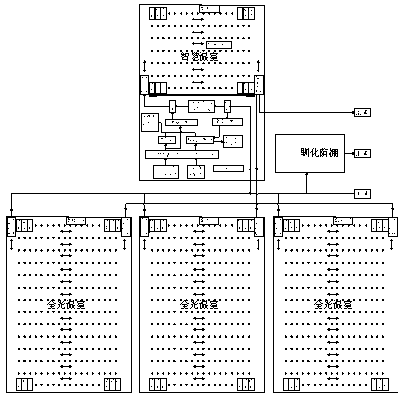

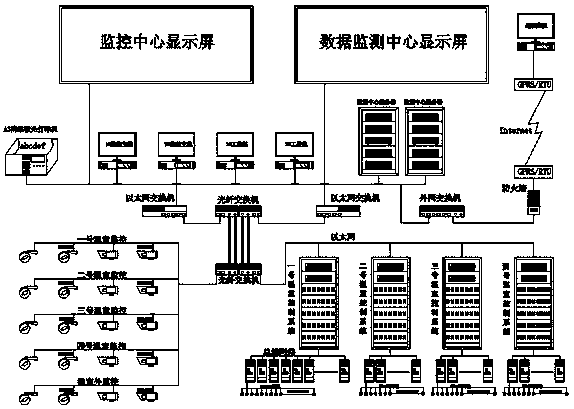

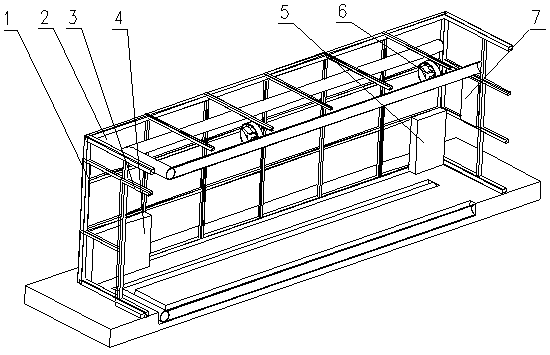

[0037]Specific embodiments of the present invention will be described in detail below in conjunction with accompanying drawings, as shown in the figure, according to the technical process of industrialized seedling cultivation, the seedling raising process that needs to be completed in the greenhouse in the industrialized seedling raising area mainly includes: preparation of nutrient soil, potting of nutrient soil , seed germination, seedling sowing, cutting seedling cultivation, seedling cutting, tissue culture seedling transplantation, greenhouse cultivation, domestication and hardening, etc., from the diverse needs of different varieties of plants for the growth environment and the industrial seedling operation In consideration of convenience, the greenhouses in the entire industrial nursery park are divided into three greenhouse areas according to different functions and uses, that is, three types of seedling breeding greenhouses, namely: smart greenhouses, full-light greenh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com