Method for manufacturing monascus fermented purplish red rice koji soybean sauce by using soybean residues and sauce residues

A technology for soybean paste and paste residue, which is applied in food science and other directions to achieve the effects of increasing amino acid nitrogen content, enriching flavor and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

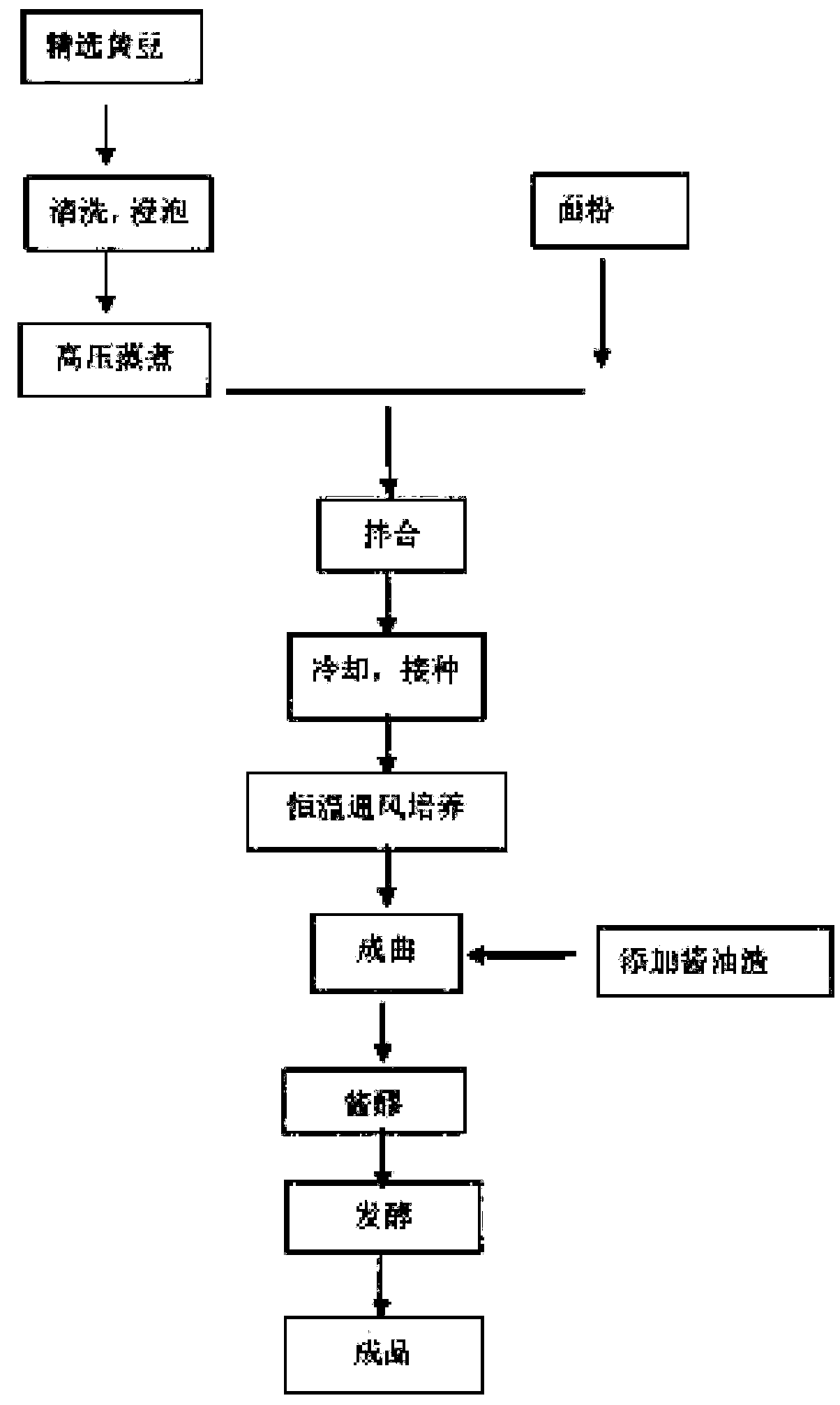

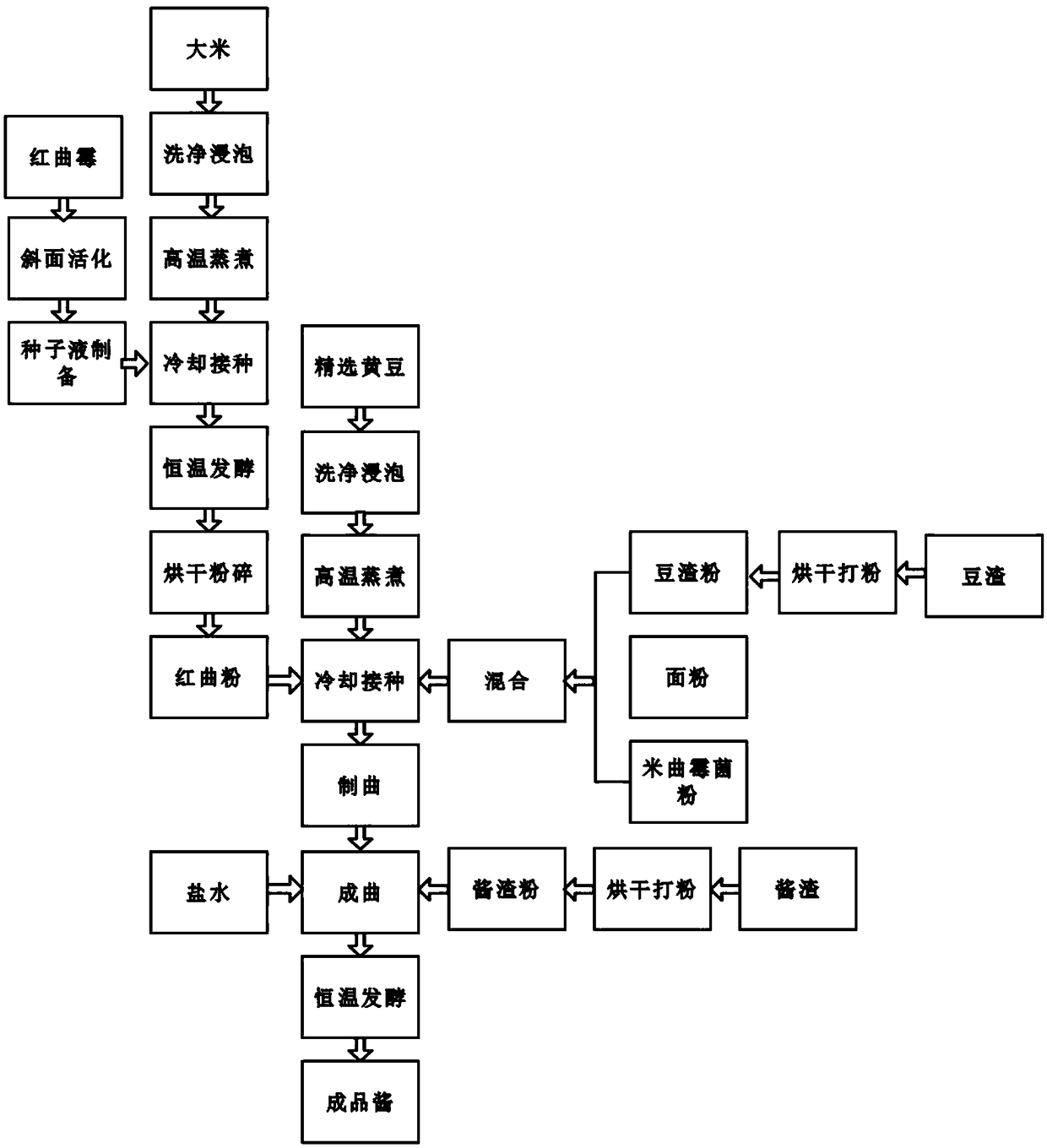

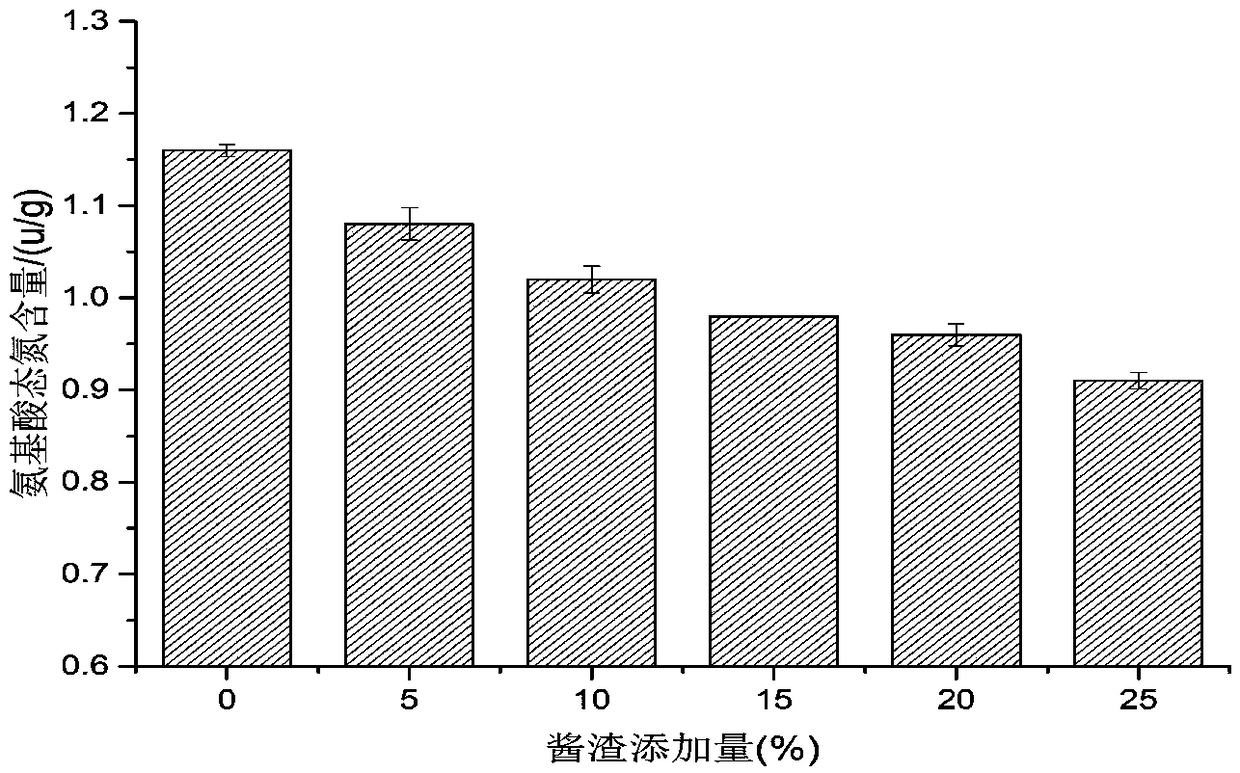

Method used

Image

Examples

Embodiment 1

[0048] A method for making red yeast soybean paste by using bean dregs and sauce dregs, the steps are as follows:

[0049] (1) Raw material pretreatment: drying the bean dregs and bean dregs, crushing and sieving to obtain bean dregs powder, and the processed bean dregs are dried and stored for later use;

[0050] (2) Production of red yeast rice powder: a. Bacterial solution preparation: Inoculate Monascus fungus stored in a refrigerator at 4°C on a test tube slope for activation (PDA agar medium, 30°C, 7d); Erlenmeyer shaker flask seed liquid: inoculate from the slope Into the liquid culture medium, shake the flask culture to make the seed liquid (PDA medium, 30 ℃, 180r / min, 48h);

[0051] b. Inoculation: Soak the washed rice for 12 hours, drain the water, sterilize at 121°C for 20 minutes, and inoculate the seed liquid at a ratio of 4:1g:mL after cooling.

[0052] c. Fermentation: The inoculated rice was placed in a constant temperature incubator at 30°C for continuous fer...

Embodiment 2

[0060] A method for making red yeast soybean paste by using bean dregs and sauce dregs, the steps are as follows:

[0061] (1) Raw material pretreatment: drying the bean dregs and bean dregs, crushing and sieving to obtain bean dregs powder, and the processed bean dregs are dried and stored for later use;

[0062] (2) Production of red yeast rice powder: a. Bacterial solution preparation: Inoculate Monascus fungus stored in a refrigerator at 4°C on the slant of a test tube for activation (PDA agar medium, 28°C, 8d); Erlenmeyer shaker flask seed liquid: inoculate from the slant Into the liquid culture medium, shake the flask culture to make seed liquid (PDA medium, 28 ℃, 150r / min, 60h);

[0063] b. Inoculation.: Soak the washed rice for 8 hours, drain the water, sterilize at 121°C for 15 minutes, and inoculate the seed liquid at a ratio of 3:1g:mL after cooling.

[0064] c. Fermentation: The inoculated rice was placed in a constant temperature incubator at 28°C for continuous ...

Embodiment 3

[0072] A method for making red yeast soybean paste by using bean dregs and sauce dregs, the steps are as follows:

[0073] (1) Raw material pretreatment: drying the bean dregs and bean dregs, crushing and sieving to obtain bean dregs powder, and the processed bean dregs are dried and stored for later use;

[0074] (2) Production of red yeast rice powder: a. Bacterial solution preparation: Inoculate Monascus fungus stored in a refrigerator at 4°C on a test tube slope for activation (PDA agar medium, 30°C, 7d); Erlenmeyer shaker flask seed liquid: inoculate from the slope Into the liquid culture medium, shake the flask culture to make seed liquid (PDA medium, 30 ℃, 200r / min, 48h);

[0075] b. Inoculation.: Soak the washed rice for 12 hours, drain the water, sterilize at 121°C for 20 minutes, and inoculate the seed liquid at a ratio of 4:1g:mL after cooling.

[0076] c. Fermentation: The inoculated rice was placed in a constant temperature incubator at 30°C for continuous fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com