A Fischer-Tropsch Synthesis Slurry Bed Reactor Containing Shell and Tube Heat Exchangers

A Fischer-Tropsch synthesis and reactor technology, applied in the direction of heat exchangers, indirect heat exchangers, heat exchanger types, etc., can solve the problems of low waste heat utilization efficiency, low Fischer-Tropsch synthesis efficiency, poor gas dredging effect, etc., to achieve High processing efficiency, improving work efficiency and quality, and improving anti-blocking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained in conjunction with specific implementations below.

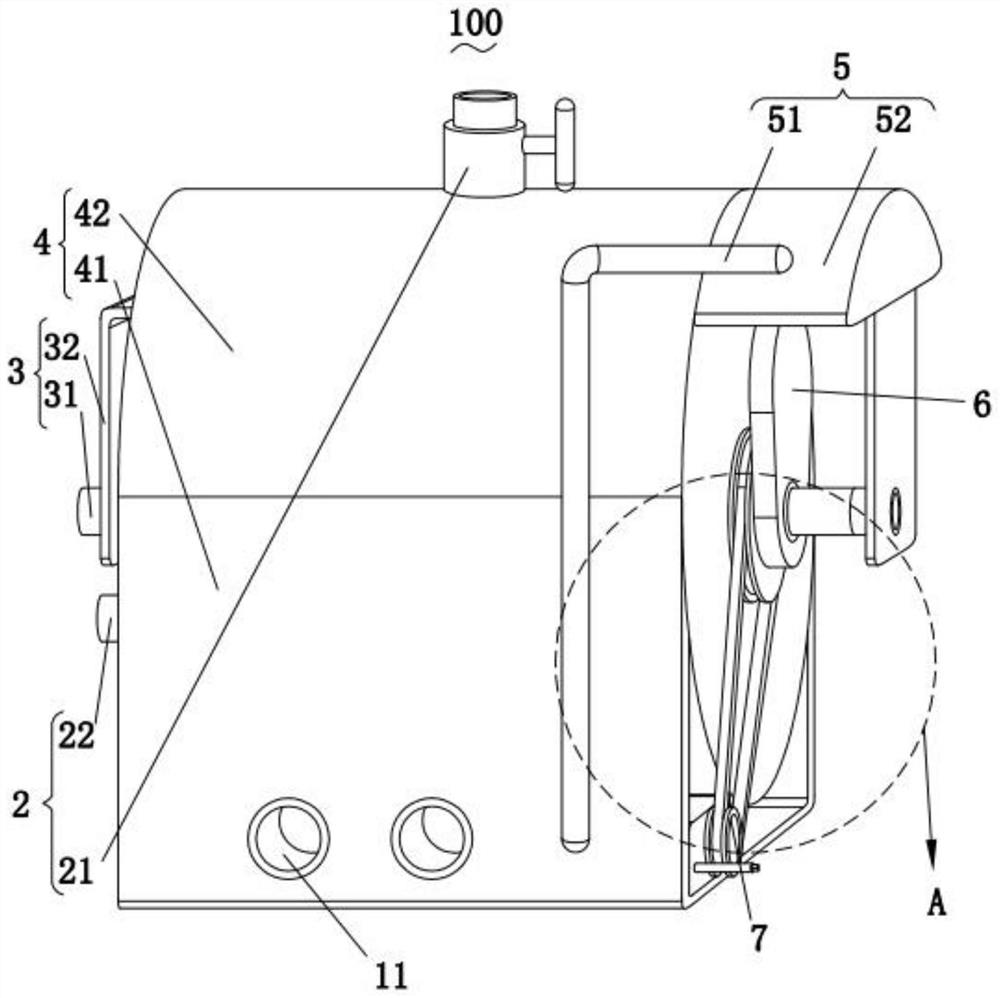

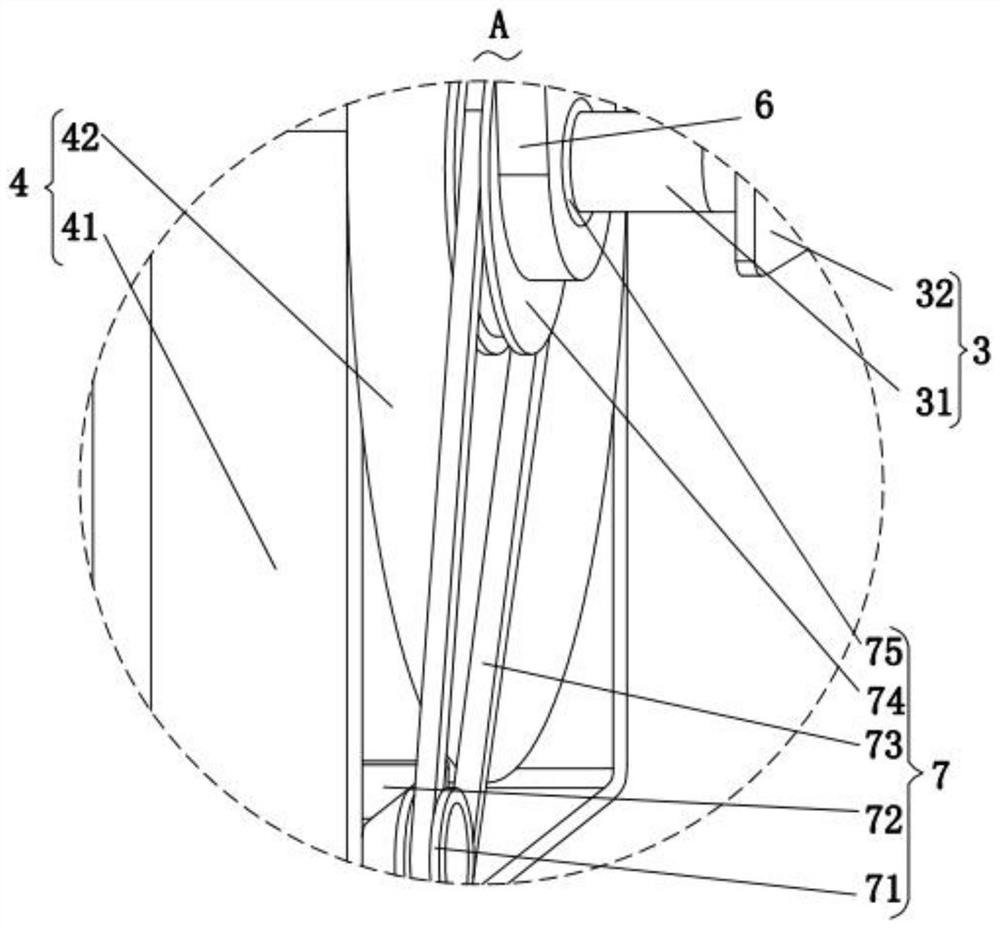

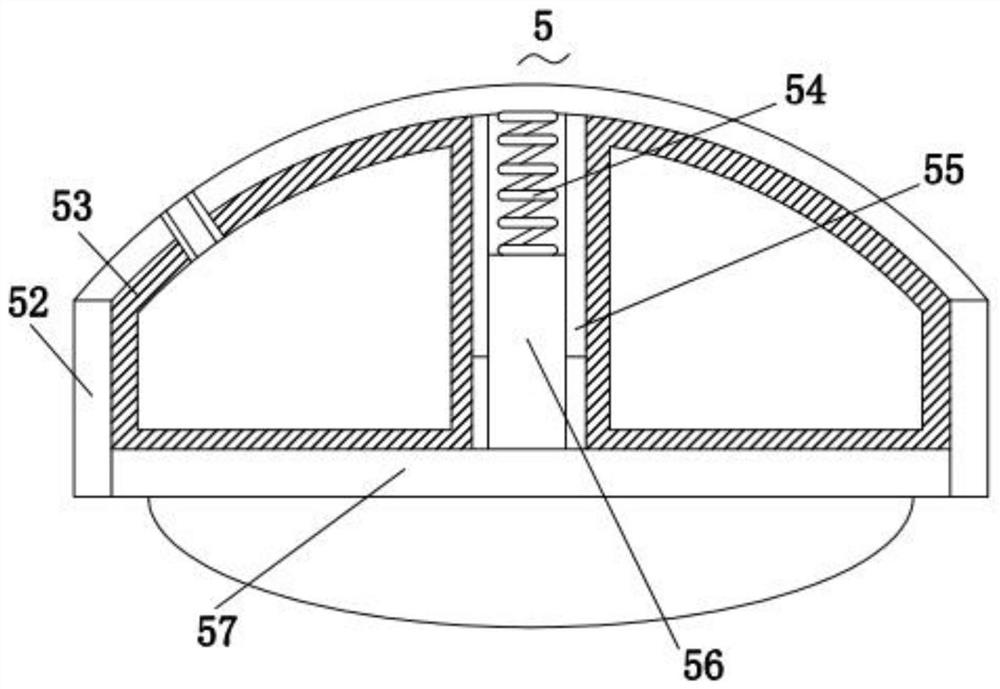

[0028]Such asfigure 1 ,Figure 4 ,Figure 5 withFigure 6As shown, the Fischer-Tropsch synthesis slurry bed reactor including the tubular heat exchanger according to the present invention includes a preheating structure 100, a gas inlet 200, a raw material inlet 300, a heat exchange medium inlet 400, and a fluid distributor 500, thermocouple insertion port 600, heat exchange tube 700, pipe 800, heat exchanger lumps 900, heat exchange medium outlet 900a and reactor liquid phase outlet 900b; the preheating structure 100 includes a storage structure 1, cooling Structure 2, diversion structure 3, storage structure 4, first drive structure 5, cam 6, second drive structure 7, waste heat utilization structure 8 and adjustment structure 9; the storage structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com