Acid modified metal-organic framework material and preparation method thereof

A technology of metal-organic framework and acid modification, applied in chemical instruments and methods, fuel cells, climate sustainability, etc., can solve the problems of limiting the application of fuel cell electrolytes, low proton conductivity, poor chemical stability, etc., to achieve Excellent proton conductivity, improved proton conductivity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

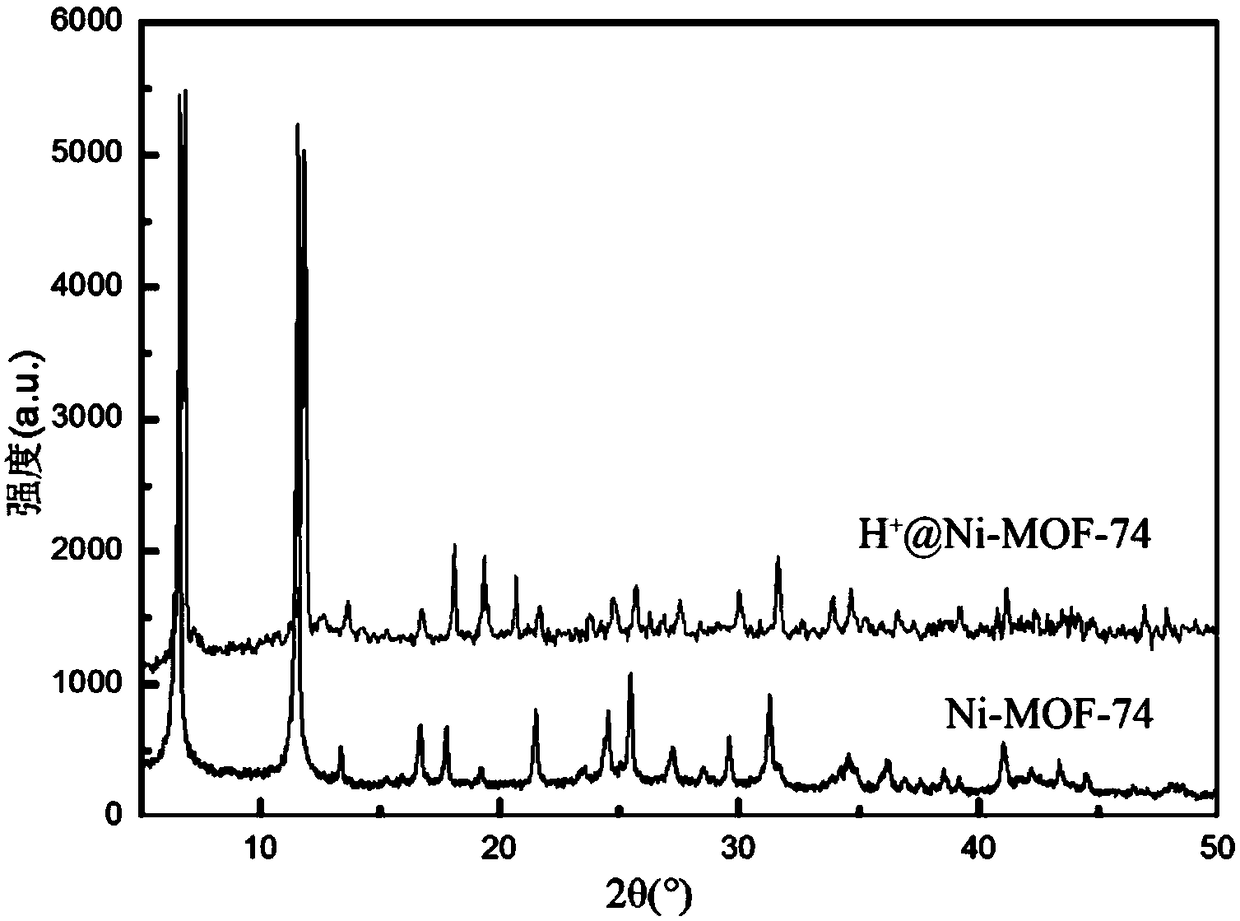

[0043]A kind of acid-modified metal-organic framework material H + The preparation method of @Ni-MOF-74, the steps are as follows:

[0044] 1) Mix 20mL N,N-dimethylformamide, 1mL absolute ethanol and 1mL deionized water, and divide them into A solution and B solution;

[0045] 2) Add 0.778g of nickel acetate to solution A, and sonicate for 15 minutes to obtain solution C;

[0046] 3) Add 0.198g of 2,5-dihydroxyterephthalic acid to solution B, and ultrasonicate for 15 minutes to obtain solution D;

[0047] 4) Under magnetic stirring, add solution C to solution D dropwise to produce a light green precipitate, stir for 15 minutes, centrifuge at 8000r / min for 15 minutes, and collect solid matter;

[0048] 5) washing the solid matter with methanol for 4 times, each time for 12 hours, and vacuum drying at 60° C. for 6 hours to obtain the metal organic framework material Ni-MOF-74;

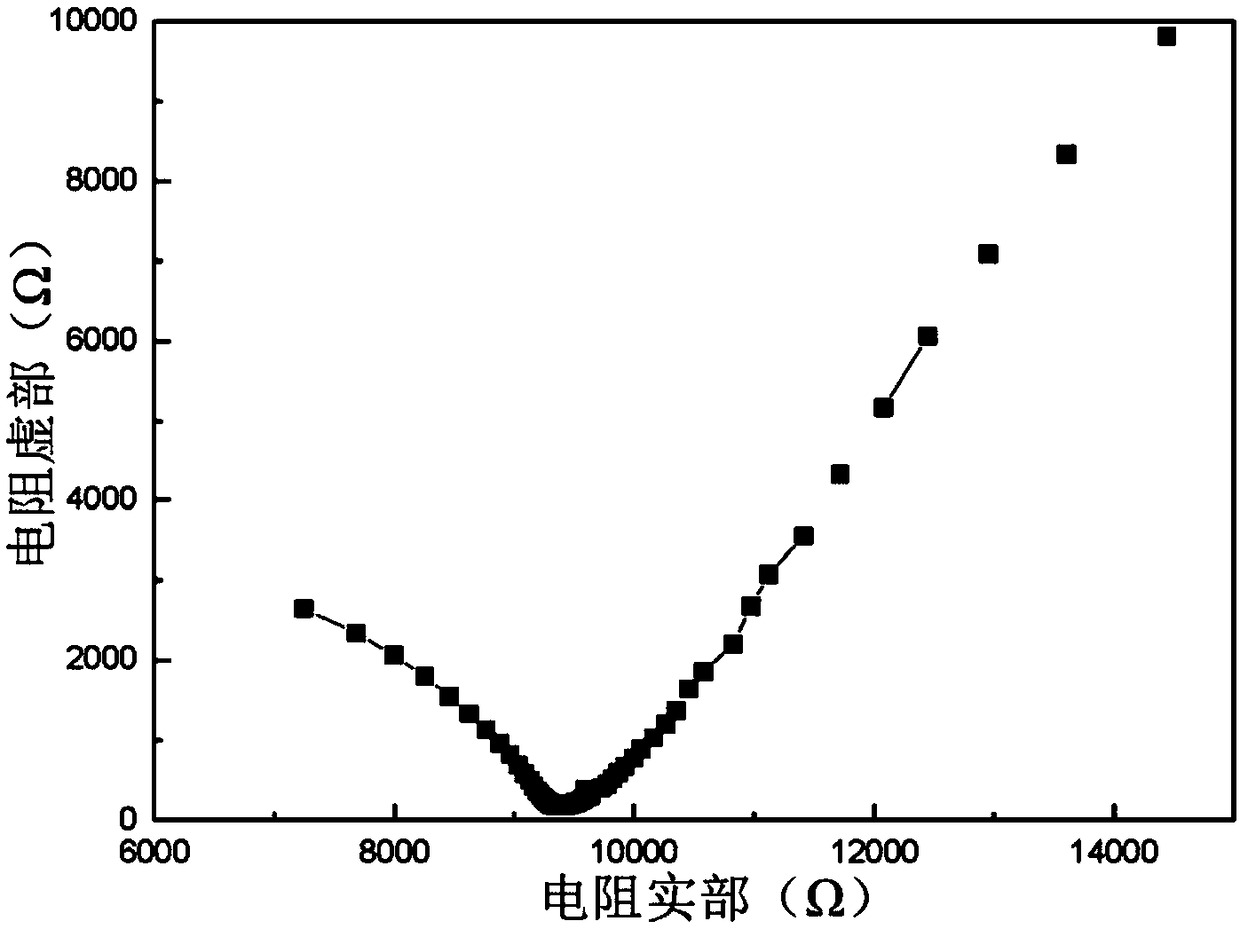

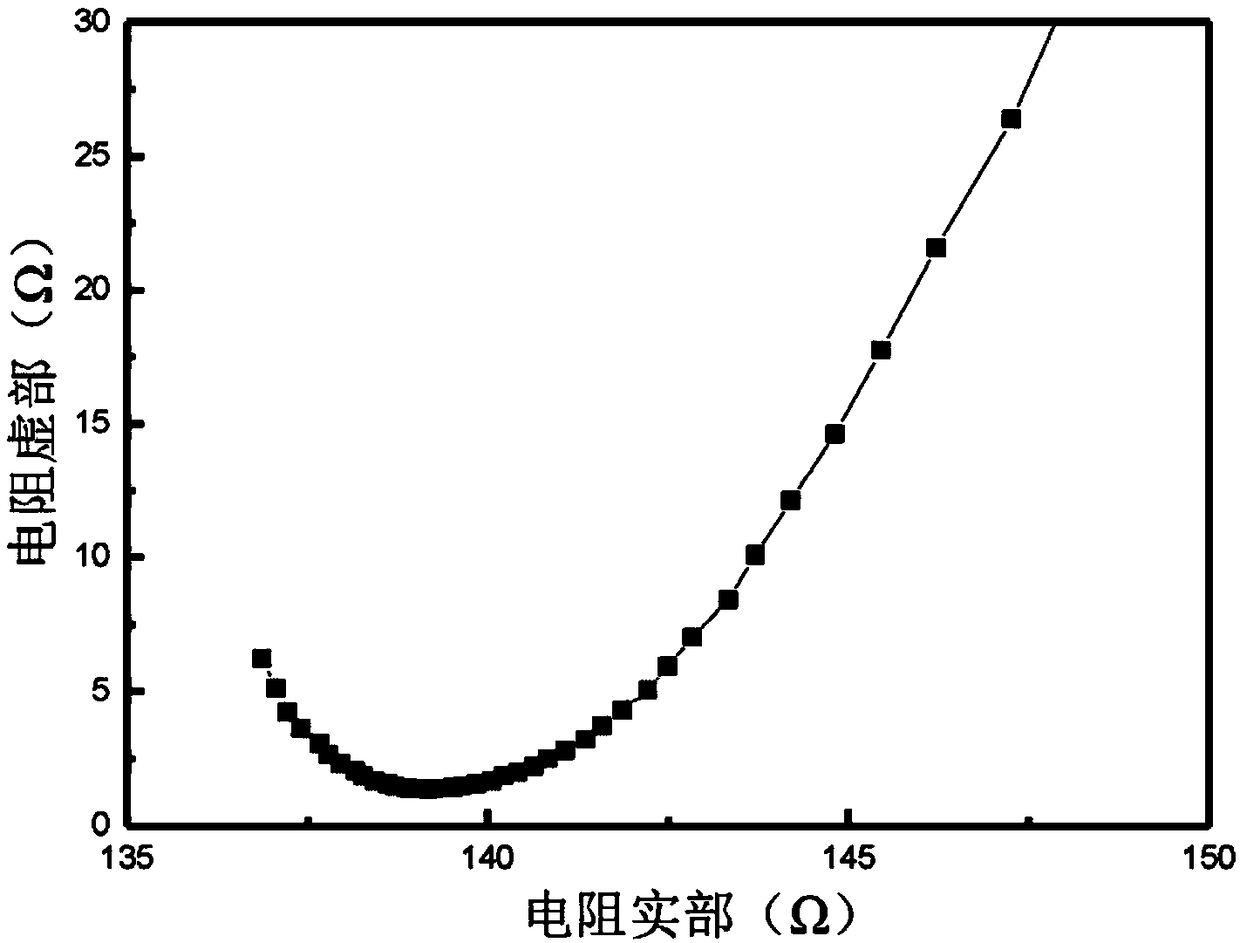

[0049] 6) Add the metal-organic framework Ni-MOF-74 obtained in step 5) into 20 mL of sulfuric aci...

Embodiment 2

[0061] A kind of acid-modified metal-organic framework material H + The preparation method of @Zn-MOF-74, the steps are as follows:

[0062] 1) Mix 20mL N,N-dimethylformamide and 1mL absolute ethanol, and divide into A solution and B solution equally;

[0063] 2) Add 0.686g of zinc acetate to solution A, and ultrasonicate for 10 minutes to obtain solution C;

[0064] 3) Add 0.198g of 2,5-dihydroxyterephthalic acid to solution B, and ultrasonicate for 10 minutes to obtain solution D;

[0065] 4) Under magnetic stirring, add solution C to solution D dropwise to produce a yellow precipitate, stir for 15 minutes, centrifuge at 7000r / min for 10 minutes, and collect solid matter;

[0066] 5) washing the solid matter with methanol for 4 times, each time for 8 hours, and vacuum drying at 50° C. for 6 hours to obtain the metal organic framework material Zn-MOF-74;

[0067] 6) Add the metal-organic framework material Zn-MOF-74 obtained in step 5) into 15 mL of phosphoric acid solutio...

Embodiment 3

[0078] A kind of acid-modified metal-organic framework material H + The preparation method of @Co-MOF-74, the steps are as follows:

[0079] 1) Mix 20mL N,N-dimethylformamide and 1mL absolute ethanol, and divide into A solution and B solution equally;

[0080] 2) Add 0.778g of cobalt acetate to solution A, and sonicate for 15 minutes to obtain solution C;

[0081] 3) Add 0.198g of 2,5-dihydroxyterephthalic acid to solution B, and ultrasonicate for 15 minutes to obtain solution D;

[0082] 4) Under magnetic stirring, add solution C to solution D dropwise to produce light yellow precipitate, stir for 10 minutes, and centrifuge at 8000r / min for 10 minutes to collect solid matter;

[0083] 5) washing the solid material with methanol for 6 times, each time for 12 hours, and drying in vacuum at 50° C. for 6 hours to obtain the metal organic framework material Co-MOF-74;

[0084] 6) Add the metal-organic framework material Co-MOF-74 obtained in step 5) into 20 mL of sulfuric acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com