Surface coating method for automatic press forming of spherical powder

A spherical powder and automatic pressing technology, which is applied in the field of powder metallurgy, can solve the problems of poor density, need for manual weighing, and large changes in filter element size, so as to achieve good product size consistency, realize mass production, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Put 80kg of Cu with a particle size of 180μm-250μm 90 Sn 10 The aerosolized spherical powder is put into a blender with a stirring and heating device. The volume of the blender is 150L. The temperature of the blender is set to 80°C. After the temperature rises, the blender is turned on. The powder was heated and stirred for 0.5h.

[0023] (2) Add 320g of a powdered epoxy resin coating agent with a particle size of 50-100μm to the mixer, keep the mixer at 80°C, and then heat and stir for 2h.

[0024] (3) Add 2.4kg ethyl acetate as a dispersant to the blender, keep the blender at 80℃ and mix for 1 hour, then open the vent of the blender and continue mixing for 2 hours, after the dispersant is completely volatilized Stop mixing.

[0025] (4) The agglomerated mixture is crushed and sieved through 60 meshes to obtain spherical powder with a coating layer.

[0026] The forming efficiency of the above method is 12 pieces / minute, and the crushing strength of the obtained filter el...

Embodiment 2

[0028] (1) Put 50kg of Cu89Sn with a particle size of 120μm-180μm 8 Zn 3 The aerosolized spherical powder is put into a blender with a stirring and heating device. The volume of the blender is 150L. Set the temperature of the blender to 60℃. After the temperature rises, turn on the blender. The powder was heated and stirred for 0.5h.

[0029] (2) Add 150g of powdered phenolic resin coating agent with a particle size of 100-150μm to the mixer, keep the mixer at 60°C, and then heat and stir for 2h.

[0030] (3) Add 2kg of ethanol as dispersant to the blender, keep the blender at 60℃, mix for 1h, then open the vent of the blender, continue mixing for 2h, stop the blending after the dispersant is completely volatilized .

[0031] (4) The agglomerated mixture is crushed and sieved through 80 mesh to obtain mixed spherical powder.

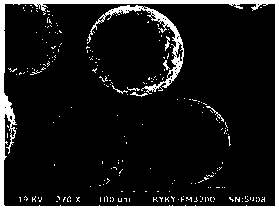

[0032] From figure 1 with figure 2 It can be seen that the surface of the uncoated powder is smooth without obvious attachments. The surface of the coated po...

Embodiment 3

[0036] (1) Put 50kg of 316L stainless steel spherical powder with a particle size of 120μm-180μm into a blender with a stirring and heating device. The volume of the blender is 150L, and the temperature of the blender is set to 100°C. After the temperature rises, the blender is turned on and the powder is heated and stirred for 0.5h.

[0037] (2) Add 500g of powdered polyurethane coating agent with particle size of 100-200μm to the mixer, keep the mixer at 100°C, and then heat and stir for 2.5h.

[0038] (3) Add 2.5kg of acetone as a dispersant to the blender, keep the blender at 100℃, mix for 2h, then open the vent of the blender, continue mixing for 2h, and stop mixing after the dispersant is completely volatilized material.

[0039] (4) The agglomerated mixture is crushed and sieved through 60 meshes to obtain spherical powder with a coating layer.

[0040] The forming efficiency of the above method is 8 pieces / minute, and the crushing strength of the obtained filter element is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com