A surface coating method for automatic compression molding of spherical powder

A spherical powder, automatic pressing technology, applied in the field of powder metallurgy, can solve problems such as uneven distribution, low efficiency, and large change in filter element size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) 80kg of Cu with a particle size of 180μm-250μm 90 sn 10 Put the gas-atomized spherical powder into a mixer with a stirring and heating device. The volume of the mixer is 150L. Set the temperature of the mixer to 80°C. After the temperature rises, turn on the mixer. The powder was heated and stirred for 0.5h.

[0023] (2) Add 320 g of powdered epoxy resin coating agent with a particle size of 50-100 μm into the mixer, keep the mixer at 80° C., and then heat and stir for 2 hours.

[0024] (3) Add 2.4 kg of ethyl acetate as a dispersant to the mixer, keep the mixer at 80°C, mix for 1 hour, then open the vent hole of the mixer, and continue mixing for 2 hours until the dispersant is completely volatilized Stop mixing.

[0025] (4) Break the agglomerated mixture, and sieve through 60 meshes to obtain a spherical powder with a coating layer.

[0026] The forming efficiency of the above method is 12 pieces / minute, and the crushing strength of the obtained filter elemen...

Embodiment 2

[0028] (1) 50kg of Cu89Sn with a particle size of 120μm-180μm 8 Zn 3 Put the gas-atomized spherical powder into a mixer with a stirring and heating device. The volume of the mixer is 150L. Set the temperature of the mixer to 60°C. After the temperature rises, turn on the mixer. The powder was heated and stirred for 0.5h.

[0029] (2) Add 150 g of powdered phenolic resin coating agent with a particle size of 100-150 μm into the mixer, keep the temperature of the mixer at 60° C., and then heat and stir for 2 hours.

[0030] (3) Add 2kg of ethanol as a dispersant to the mixer, keep the mixer at 60°C, mix for 1 hour, then open the vent hole of the mixer, continue mixing for 2 hours, stop mixing after the dispersant is completely volatilized .

[0031] (4) Crush the agglomerated mixture, and sieve through 80 meshes to obtain a mixed spherical powder.

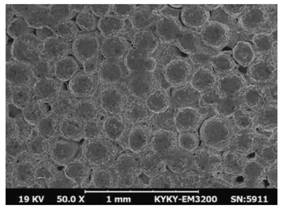

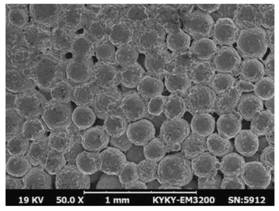

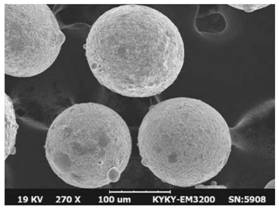

[0032] From figure 1 and figure 2 It can be seen from the figure that the surface of the uncoated powder is smooth and there...

Embodiment 3

[0036] (1) Put 50 kg of 316L stainless steel spherical powder with a particle size of 120 μm-180 μm into a mixer with a stirring and heating device, wherein the volume of the mixer is 150 L, and the temperature of the mixer is set to 100 ° C, After the temperature rises, turn on the mixer and heat and stir the powder for 0.5h.

[0037] (2) Add 500 g of powdered polyurethane coating agent with a particle size of 100-200 μm into the mixer, keep the temperature of the mixer at 100° C., and then heat and stir for 2.5 hours.

[0038] (3) Add 2.5kg of acetone as a dispersant to the mixer, keep the mixer at 100°C, mix for 2 hours, then open the vent hole of the mixer, continue mixing for 2 hours, stop mixing after the dispersant is completely volatilized material.

[0039] (4) Break the agglomerated mixture, and sieve through 60 meshes to obtain a spherical powder with a coating layer.

[0040] The forming efficiency of the above method is 8 pieces / minute, and the crushing strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com