A kind of preparation method and application of biomass activated semi-coke catalyst

A biomass and catalyst technology, which is applied in the field of preparation of biomass activated semi-coke catalysts, can solve the problems of reducing the catalyst surface area and catalytic activity, and achieve the effects of reducing costs, improving energy utilization, and developing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

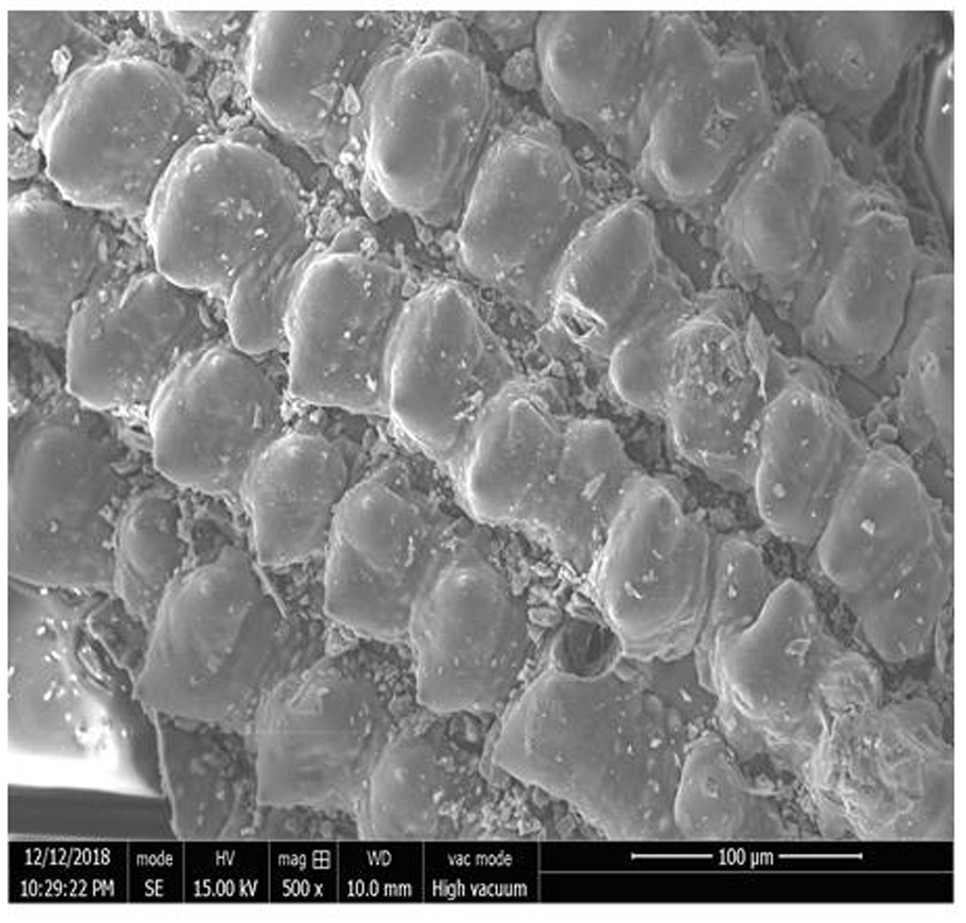

[0031] Weigh 1 g of rice husks with a moisture content of 5% and a particle size between 250 μm and 600 μm in terms of mass percentage, and place it in a fixed-bed reactor under N 2 In the process, the temperature was raised to 800°C at a heating rate of 10°C / min, held for 1h, cooled down to room temperature, and a pyrolyzed biomass semi-coke catalyst was obtained, coded as A.

Embodiment 2

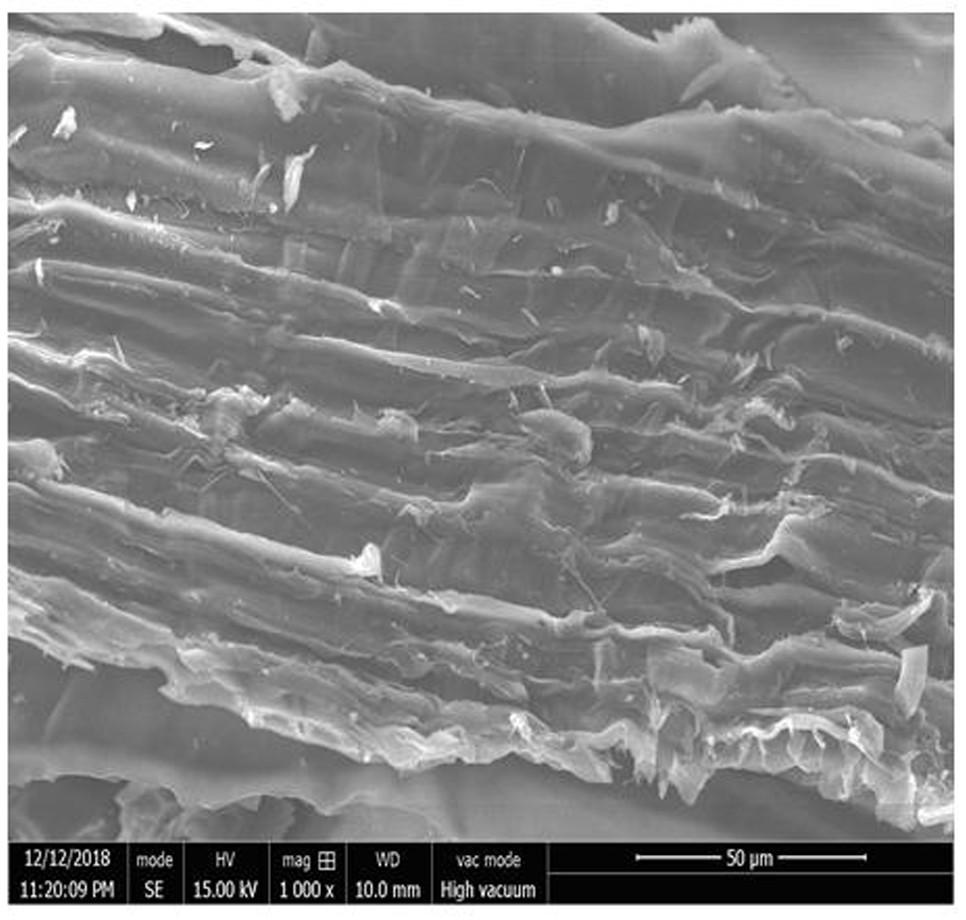

[0033] Weigh 1 g of wood chips with a moisture content of 5% and a particle size between 250 μm and 600 μm in terms of mass percentage, and place it in a fixed-bed reactor under N 2 In the process, the temperature was raised to 800°C at a heating rate of 10°C / min, held for 1h, and cooled down to room temperature to obtain a pyrolyzed biomass semi-coke catalyst, coded as B.

Embodiment 3

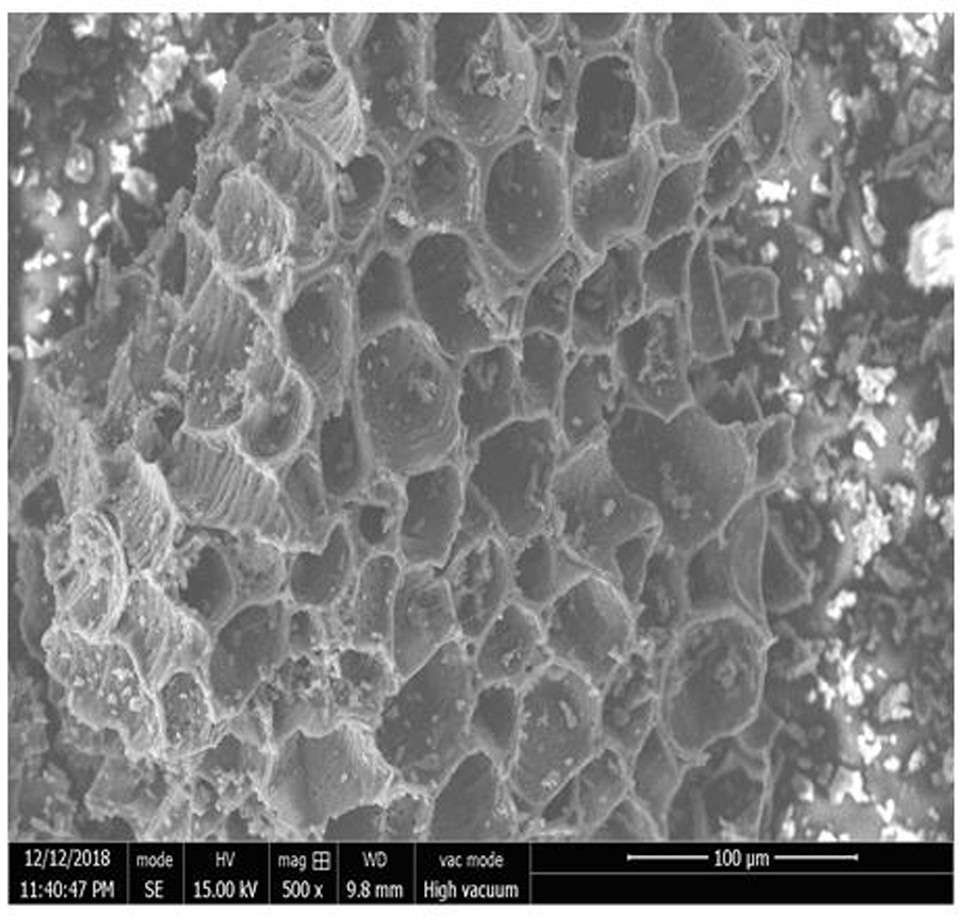

[0035]Weigh 1 g of corn cobs with a moisture content of 5% and a particle size between 250 μm and 600 μm in terms of mass percentage, place it in a fixed-bed reactor, and heat up at a rate of 10°C / min in helium Raise the temperature to 800° C., keep it for 1 hour, cool down to room temperature, and obtain a pyrolyzed biomass semi-coke catalyst, coded as C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com