A kind of cemented carbide strip/block and its bonding method suitable for cemented carbide hard surface processing

A hard alloy, one-sided technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of hard alloy strip/block cracks, uneven thickness of brazing layer, and many welding pores, etc., to achieve uniform thickness , increase the thickness, reduce the effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

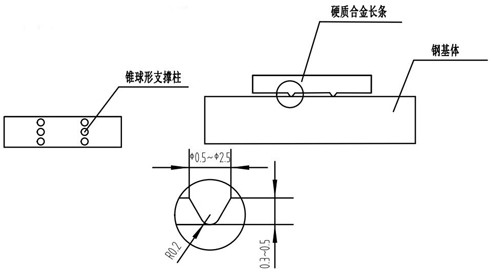

[0037] This embodiment provides a hard alloy strip / block suitable for hard alloy hard surface processed, hard alloy bar / block is a long bar shape, and the long rough hard alloy bar provided in this embodiment can be applied to screw drill. Tools, various large and medium-sized mechanics of drill rods and drilling tools, TC bearings on screw drills and various hardening occasions.

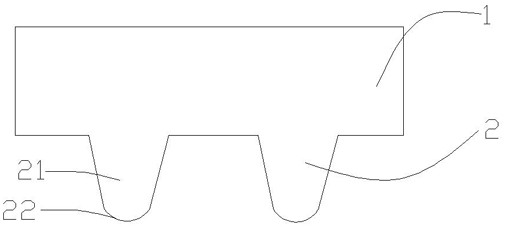

[0038] The hard alloy strip / block includes a plurality of support columns 2 integrally formed with the body 1, and the plurality of support columns 2 are disposed on the contact surface of the hard alloy strip / block and the steel matrix, the shape of the support column 2 can be Any one of a cone shape, semi-cylindrical, hemispherical, long strip, wedge or cross, in order to effectively reduce the contact area of the support post 2 and the steel matrix, facilitate the flow of brazing in the molten state, EXAMPLES The shape of the support post 2 is a cone shape, and the support post 2 includes a...

Embodiment 2

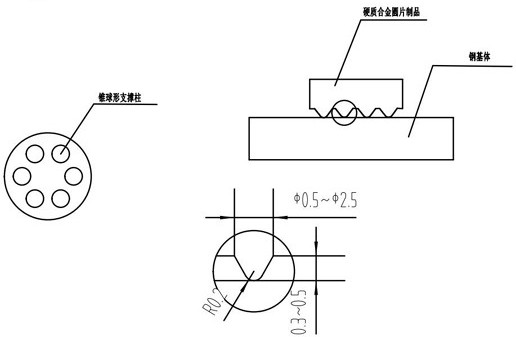

[0055] This embodiment also provides a hard alloy bar / block suitable for hard alloy hard alloy, and is different from the first embodiment, and the hard alloy bar / block of the present embodiment is a circular shape, according to this The shape of the hard alloy bar / block of the embodiment can be uniformly disposed on the same circumference according to the size of the hard alloy bar / block, and the size of the circumferential hard alloy block in the present embodiment is sized. See Table 2, according to Table 2, the size of the wafer-shaped hard alloy block of the TC bearing and the armor alloy member according to Table 2 can be uniformly set at least 6 in the same circumference of the wafer-shaped hard alloy block provided in this example. A support column, the number of support columns is preferably 6; the support column is evenly distributed over the same circumference of the wafer-shaped hard alloy block, which is advantageous to uniformly distribute the residual stress...

Embodiment 3

[0060] This embodiment also provides a hard alloy strip / block suitable for hard alloy hard surface, and is different from that of Example 1, the hard alloy strip / block of the present embodiment is a positive hexagon, according to this The shape of the hard alloy bar / block of the embodiment can be uniformly disposed on the same circumference in the same circumference according to the size of the hard alloy strip / block, and the size of the positive hexagonal hard alloy block in the present embodiment. In view of Table 3, according to Table 3, it should be used in the size of the hard alloy block of the TC bearing and the armor alloy member, and at least 6 support columns can be uniformly disposed on the same circumference of the positive hexagonal hard alloy block provided in this embodiment. The number of support columns is preferably 6; the support column is uniformly distributed over the same circumference of the positive hexagonal hard alloy block, which is advantageous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com