Preparation method of field-sensitive nonlinear conductive film, prepared film and application

A conductive film and nonlinear technology, which is applied in the field of field-sensitive nonlinear conductive film preparation, can solve problems such as damage and lower working voltage, and achieve the effects of low experimental environment requirements, easy operation, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a field-sensitive nonlinear conductive film, comprising the steps of:

[0042] (1) First, take 0.2g of PVP and add 25ml of EG, stir magnetically for 4-5 hours until completely dissolved to obtain mixed solution A.

[0043](2) Then take 0.25g AgNO 3 Add solution A, magnetically stir for about 1 h until completely dissolved to obtain a homogeneous solution B.

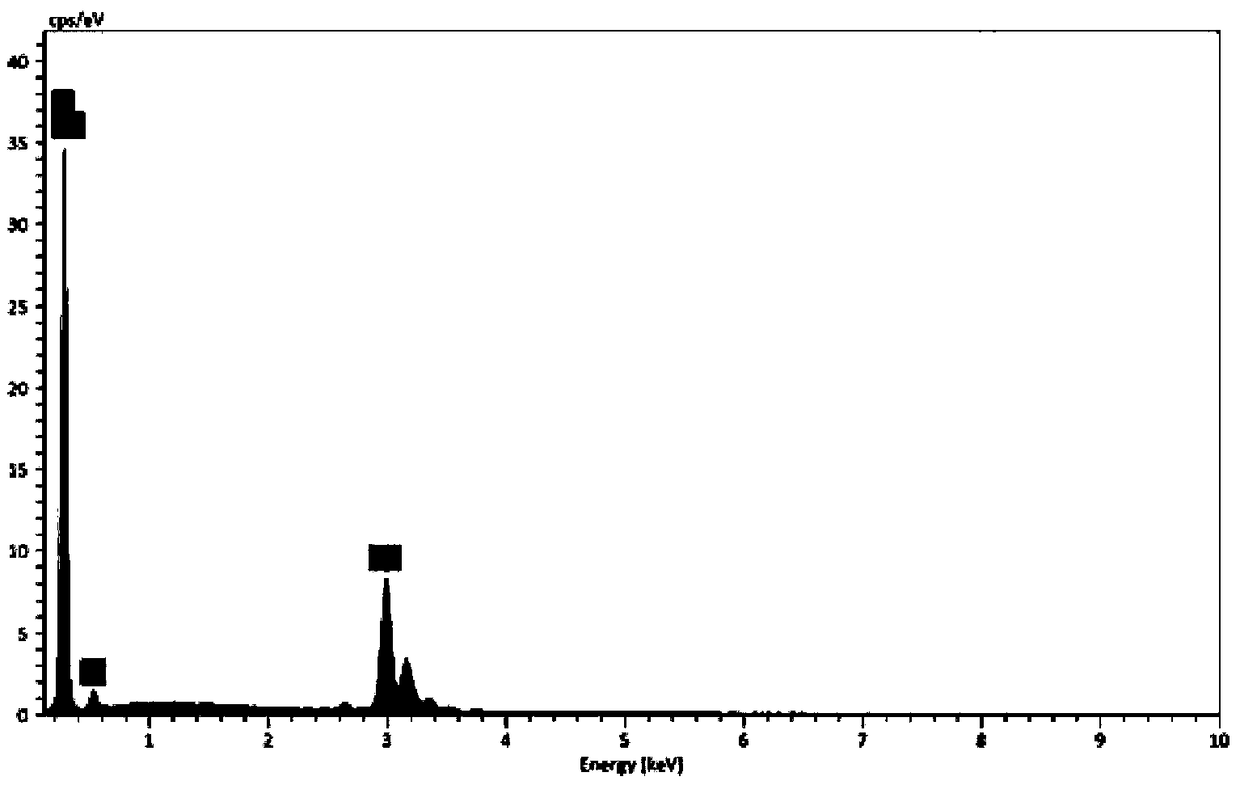

[0044] (3) Preparation of FeCl with a concentration of 600 μmol / L 3 / EG solution, and take 3.5ml FeCl 3 Add the / EG solution to solution B, and continue magnetic stirring for about 5 minutes until the solution is uniform to obtain solution C.

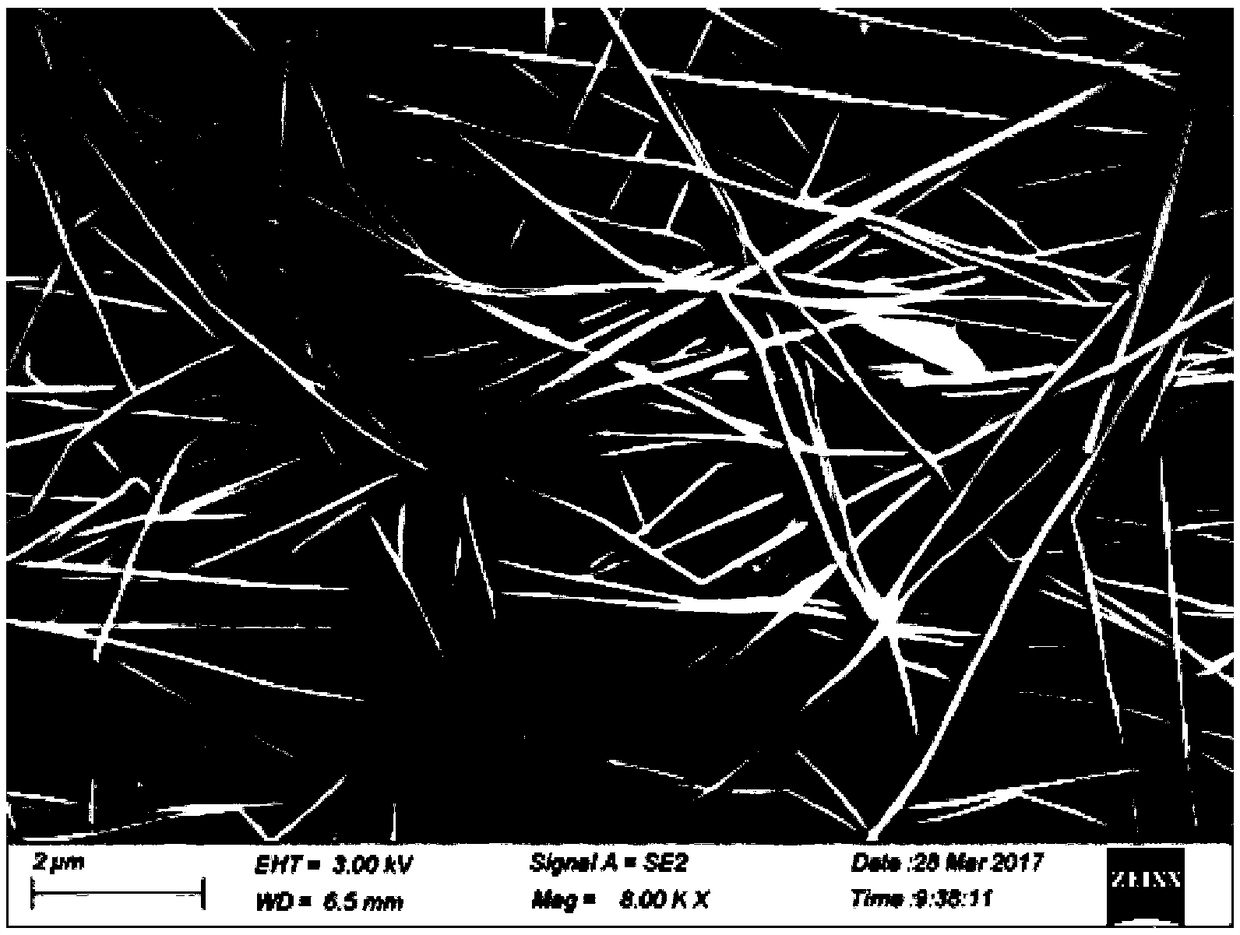

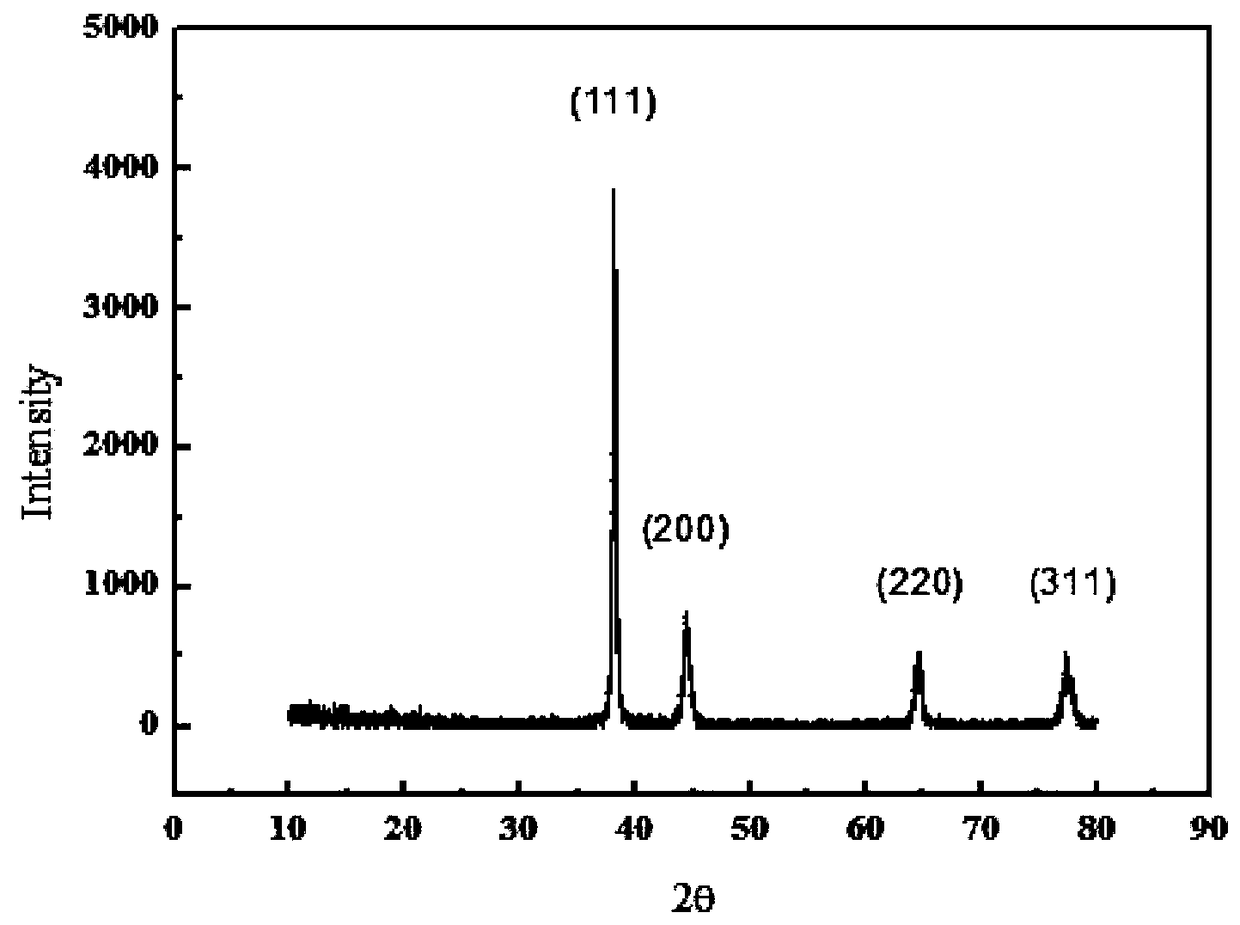

[0045] (4) Pour solution C into a 250ml round-bottomed flask, place it in a silicone oil bath at 130°C and heat for 5 hours. During the reaction, the light yellow solution gradually turns into light brown until milky white suspension D is formed. After the milky white suspension D is naturally cooled to room temperature, take it out and pour it int...

Embodiment 2

[0049] A method for preparing a field-sensitive nonlinear conductive film, comprising the steps of:

[0050] Front (1)-(5) are synchronous with embodiment 1.

[0051] (6) First weigh 5g of PVA (the degree of polymerization is 1700, and the degree of alcoholysis is 99%) and 90ml of deionized water are placed in a round-bottomed flask, and magnetically stirred for half an hour at room temperature to volatilize impurities and fully swell the PVA to Avoid endothelial growth during lysis. Then increase the temperature, heat the deionized water to 90°C, and continue to stir for about 1.5h until the PVA is completely dissolved. At this time, add 8 parts of AgNWs prepared in step (5) (among them, 1 part of AgNWs prepared in step (5) Refers to the AgNWs generated by the above steps (1)-(5) per 0.2g of PVP is referred to as 1 part), and the temperature is adjusted to 65 ° C for 10 hours to obtain a composite material fluid with a certain viscosity, the fluid Pour into a flat, clean Pe...

Embodiment 3

[0053] A method for preparing a field-sensitive nonlinear conductive film, comprising the steps of:

[0054] Front (1)-(5) are synchronous with embodiment 1.

[0055] (6) First weigh 5g of PVA (the degree of polymerization is 1700, and the degree of alcoholysis is 99%) and 90ml of deionized water are placed in a round-bottomed flask, and magnetically stirred for half an hour at room temperature to volatilize impurities and fully swell the PVA to Avoid endothelial growth during lysis. Then increase the temperature, heat the deionized water to 90°C, and continue to stir for about 1.5h until the PVA is completely dissolved. At this time, add 12 parts of AgNWs prepared in step (5) (among them, 1 part of AgNWs prepared in step (5) Refers to the AgNWs generated by the above steps (1)-(5) per 0.2g of PVP is referred to as 1 part), and the temperature is adjusted to 65 ° C and continued to stir for 15 hours to obtain a composite material fluid with a certain viscosity, the fluid Pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com