Biochar organic fertilizer with high adsorbability and preparation method and application thereof

A technology of biochar and high adsorption, which is applied in the direction of organic fertilizers, applications, fertilization devices, etc., can solve the problems of increased cost and labor, less microporous structure of biochar, and poor adsorption performance of biochar, so as to achieve good adsorption effect and absorb The effect of strong chelating ability and fast carbonization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

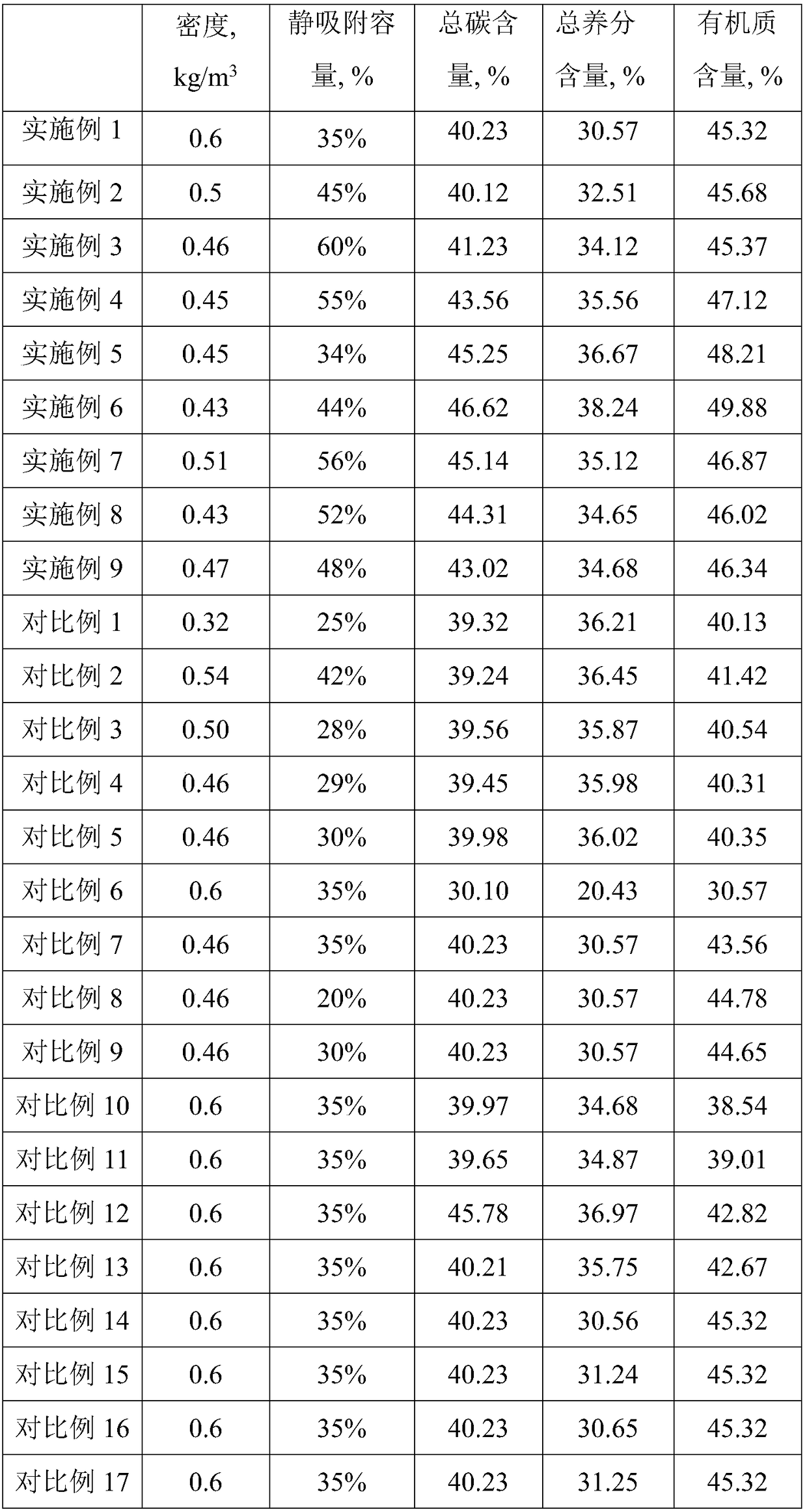

Examples

Embodiment 1

[0046] The present embodiment provides a kind of preparation method of biochar-based organic fertilizer with high adsorption performance, which specifically includes the following steps:

[0047] S1. Preparation of biochar with high adsorption performance

[0048] S11. crushing the bamboo fibers to particles with a diameter of 3 mm, and crushing the straw fibers to a length of 1 mm, for use;

[0049]S12. get the bamboo fiber 50kg that step S11 obtains and straw fiber 50kg, after fully mixing, add diesel oil 1kg, sucrose 1kg, vinyl acetate polymer latex 1kg and rosin 1kg, after mixing, pressure is 10MPa, and temperature is 25 ℃ condition Press down to form a cube fiber block, the density of the fiber block is 0.85kg / m 3 ;

[0050] Wherein, diesel oil is a mixture of heavy diesel oil and light diesel oil in a mass ratio of 0.5:1;

[0051] S13. Carry out carbonization treatment on the fiber block in step S12 under vacuum condition, the vacuum rate is 85%, carbonization treatme...

Embodiment 2

[0056] With reference to the preparation method of Example 1, the difference is: in step S12, 50 kg of bamboo fiber and 50 kg of straw fiber obtained in step S11 are taken, 1.5 kg of diesel oil, 2 kg of sucrose, 2 kg of vinyl acetate polymer latex and 2 kg of rosin are added; in step S13 , the vacuum rate is 88%; in step S2, the feces are dried to a water content of 8%, and then pulverized until the particle size is 5 mm, and then set aside.

Embodiment 3

[0058] With reference to the preparation method of Example 1, the difference is: in step S12, 50 kg of bamboo fiber and 50 kg of straw fiber obtained in step S11 are taken, 2 kg of diesel oil, 3 kg of sucrose, 3 kg of vinyl acetate polymer latex and 3 kg of rosin are added; in step S13, The vacuum rate is 95%; in step S2, the feces are dried to a water content of 7%, and then pulverized until the particle size is 8 mm, for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com