Nickel tin salt coloring, hole-sealing and recovering hole sealer and method of reclaimed water utilization and online configuration

A colorant, nickel-tin technology, applied in the field of aluminum processing, can solve the problem of lack of mature and reliable technology, and achieve the effect of realizing resource recycling and reducing industrial hazardous waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

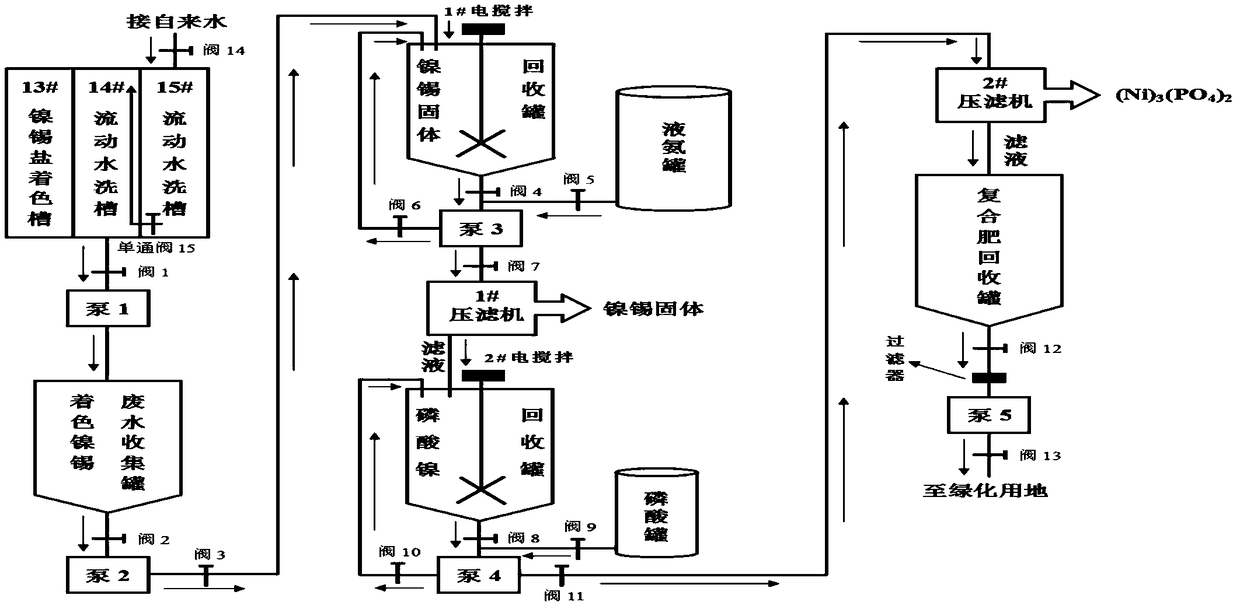

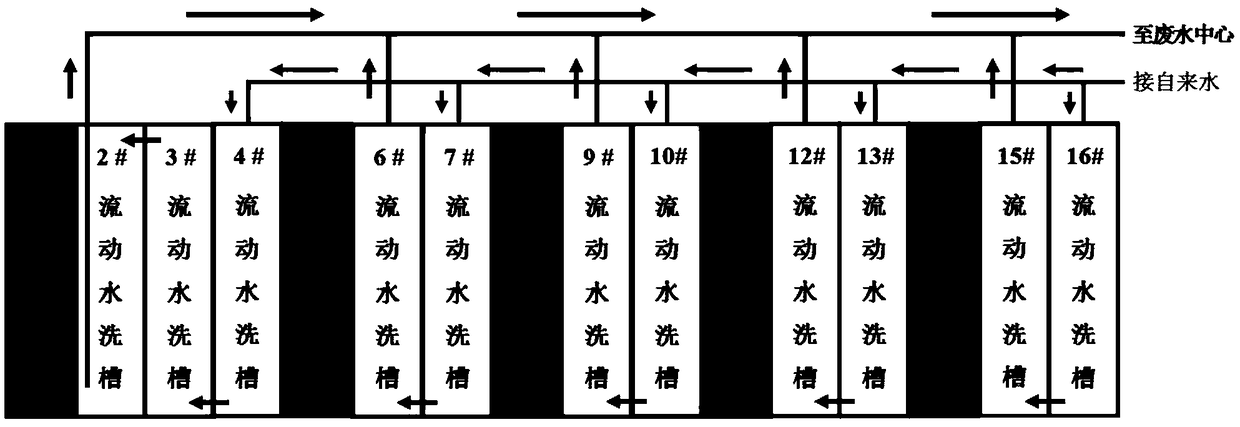

[0156] Nickel-tin salt coloring recovery colorant and reclaimed water utilization methods, including: reverse series water-saving operation, nickel-tin wastewater retention operation, nickel-tin wastewater treatment operation, nickel phosphate recovery operation and N-P compound fertilizer recovery operation;

[0157] (1) Reverse series water-saving operation includes: open valve 14, tap water enters from 15# flowing water washing tank, reversely connects to 14# flowing water washing tank through single-way valve 15, and flows from the bottom of 14# flowing water washing tank Outflow, through valve 1 and pump 1, is pumped into the colored nickel-tin wastewater collection tank;

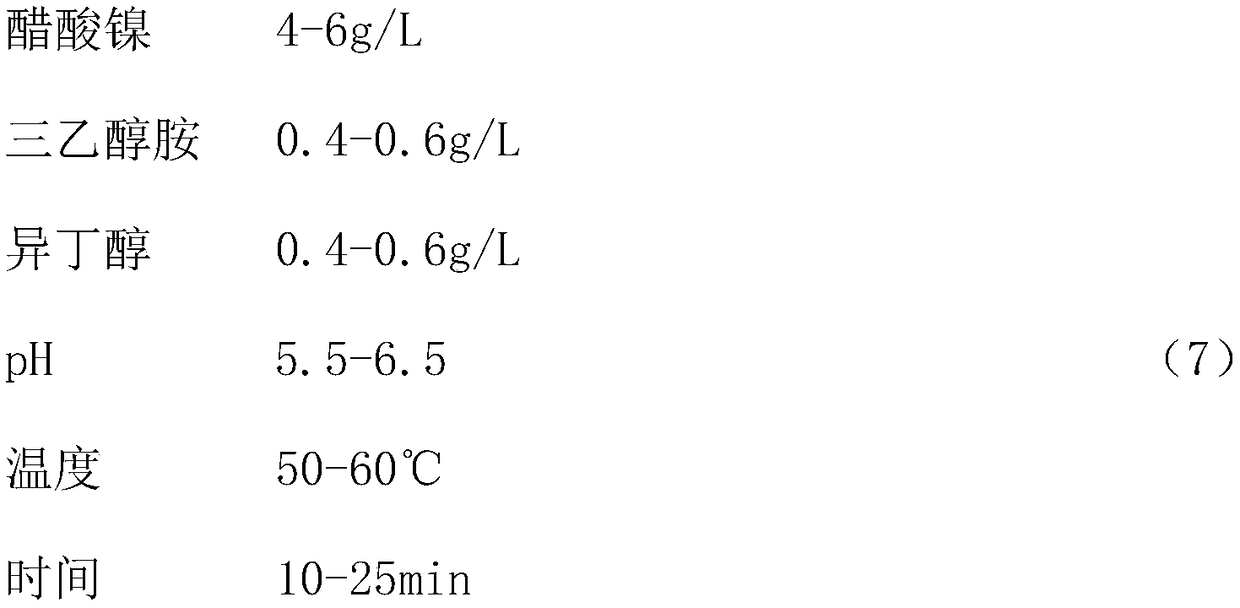

[0158] (2) The interception operation of the nickel-tin wastewater includes: using the coloring solution to color the aluminum material in a 13# nickel-tin salt coloring tank for 30s-15min, and hang and drip it for 30s; enter the colored aluminum material into a 14# flowing water washing tank Wash for ...

Embodiment 2

[0193] Embodiment 2 (the nickel-tin salt coloring liquid working ability detection that reclaims production)

[0194] according to figure 2 , continuous production of colored aluminum, 13# nickel-tin salt coloring tank is continuously added the coloring solution recovered and produced by the present invention according to the control index of formula (1); take the coloring solution pH = 1.0, temperature 25 ° C, stannous sulfate 5-10g / L (Other ingredients are calculated by (12) formula); Getting oxide film thickness is 15 microns, and coloring time is 10 minutes, and the result is as shown in table 3 below:

[0195]

[0196] Table 3 The coloring effect of different concentrations of stannous sulfate on aluminum

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com