Printing process of polyester knitted fabric

A printing process and technology for knitted fabrics, applied in textiles and papermaking, fabric surface trimming, heating/cooling fabrics, etc., can solve the problems of easy fading of patterns and low light fastness, improve color fastness, and ensure soaping Ability, uniform effect of soaping power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

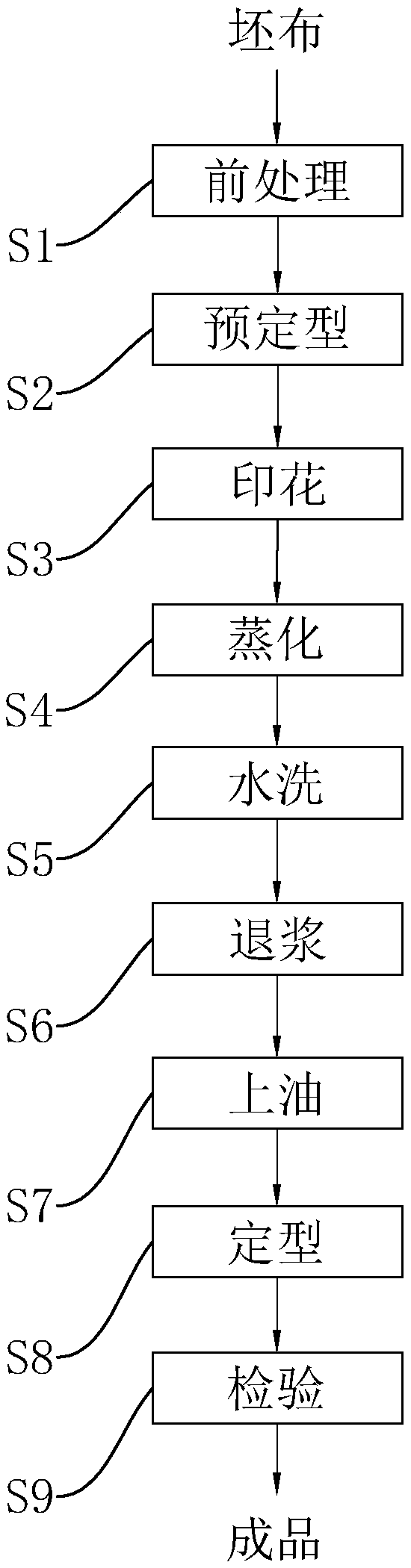

Method used

Image

Examples

Embodiment 1

[0053] The difference between Example 10 to Example 13 and Example 1 is that the parameters of the rotary screen printing machine in S3 printing are as follows:

[0054]

[0055] The difference between Example 14 to Example 18 and Example 1 is that each chemical composition of the slurry in S3 printing is calculated by mass percentage in the following table: Unit:%

[0056]

[0057] The difference between Example 19 to Example 22 and Example 1 is that the conditions in S4 steaming are as follows:

[0058]

[0059]

[0060] The difference between Example 23 to Example 26 and Example 1 is that the conditions in S8 setting are as follows:

[0061]

[0062] The difference between Example 27 to Example 31 and Example 1 is that the chemical composition of each material of the desizing agent in S6 desizing is calculated by mass percentage in the following table: Unit:%

[0063]

[0064] Color fastness is one of the important indicators of textiles. The so-called color fastness refers to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com