Automobile fastener structure

A fastener and automobile technology, applied in the field of auto parts, can solve the problems of obvious friction between metals, high process cost, and abnormal noise, so as to avoid the risk of hydrogen embrittlement, improve the overall quality, water absorption and shrinkage low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

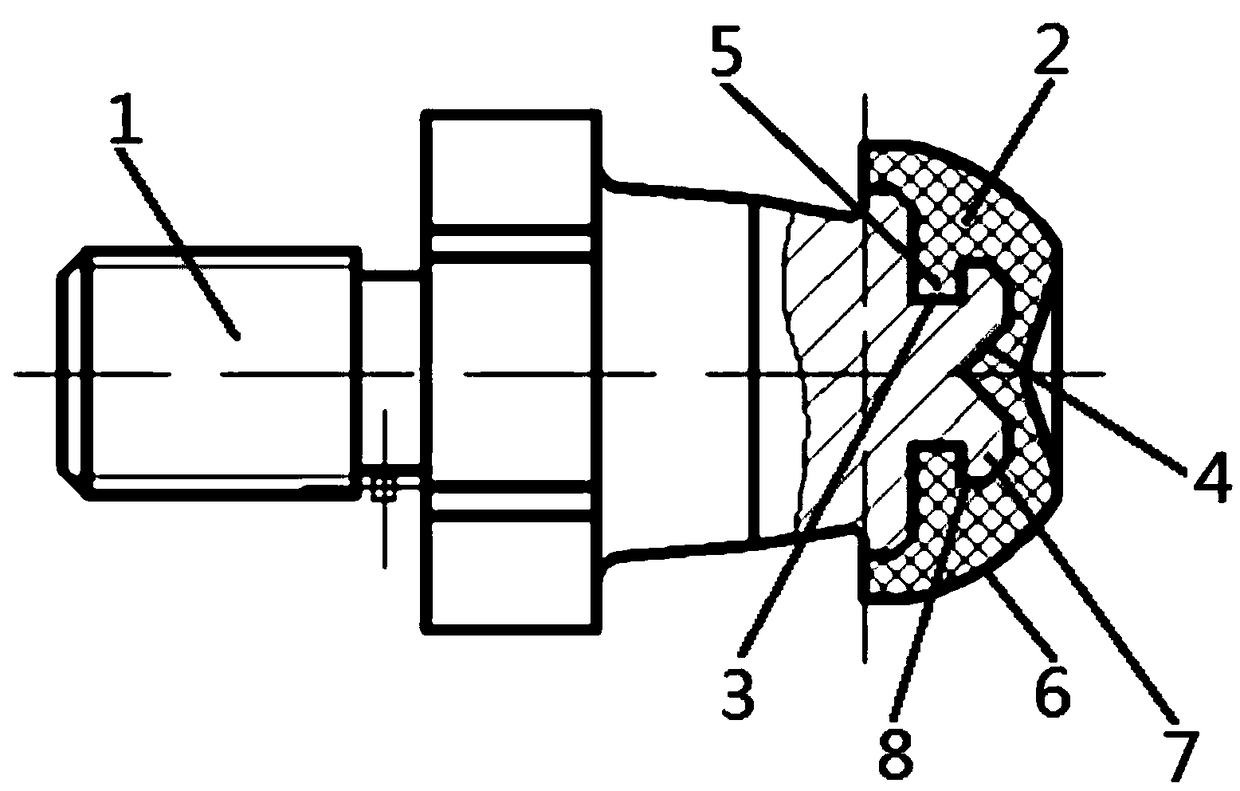

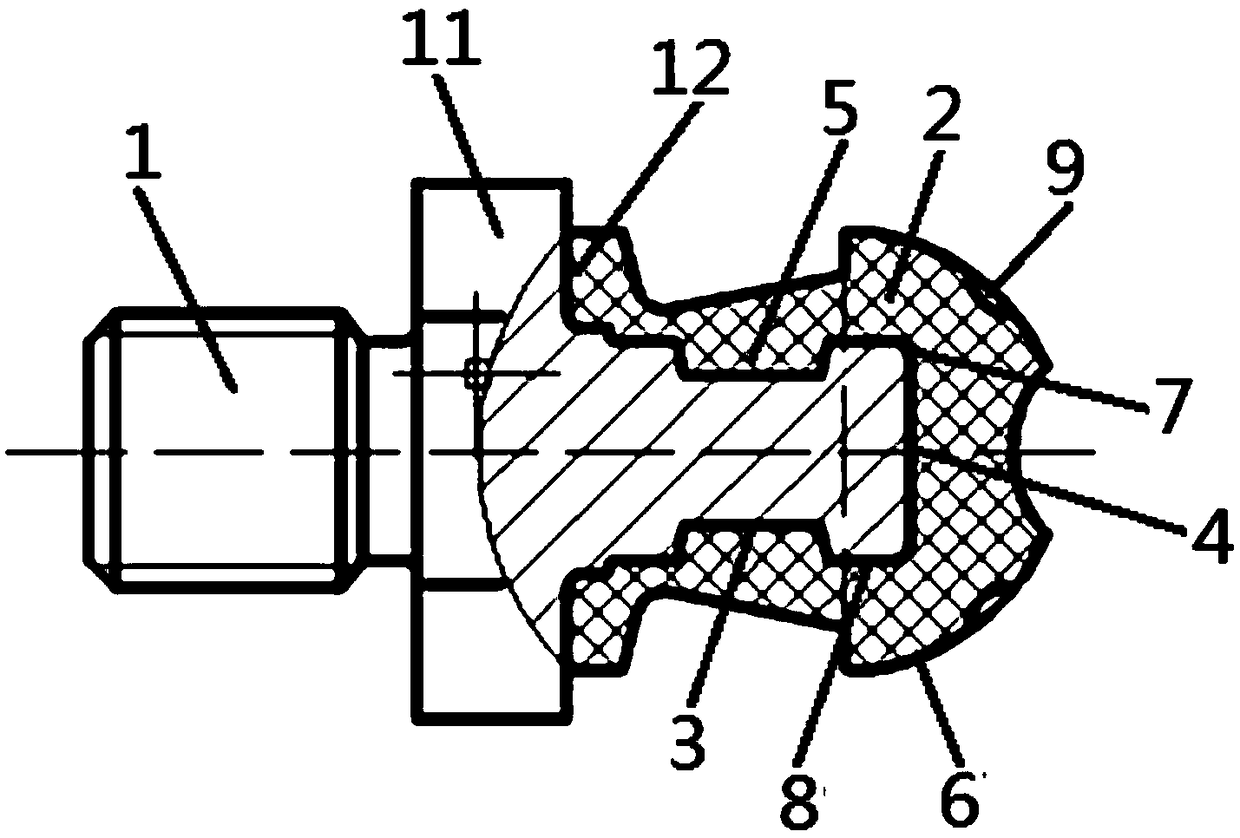

[0019] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

[0020] as attached figure 1 , attached figure 2 As shown, the present invention is a fastener structure for automobiles. The fastener structure for automobiles includes a fastener body 1 and a wear-resistant part 2. One end surface of the fastener body 1 is provided with a recessed Card slot 3, one end of the wear-resistant part 2 is provided with a suit cavity 4, one end of the wear-resistant part 2 is a protruding arc-shaped wear-resistant surface 6, the inner wall of the suit cavity 4 is provided with a protruding boss 5, and the wear-resistant part 2 passes through The sleeve chamber 4 is sleeved on one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com