Measuring device for moisture content and mineralization degree based on plug-in impedance sensor

A technology of electrical impedance and sensors, applied in the direction of measuring devices, material impedance, instruments, etc., can solve the problems of inconvenient installation, uneven distribution of electrode distance, uneven distribution of excitation field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

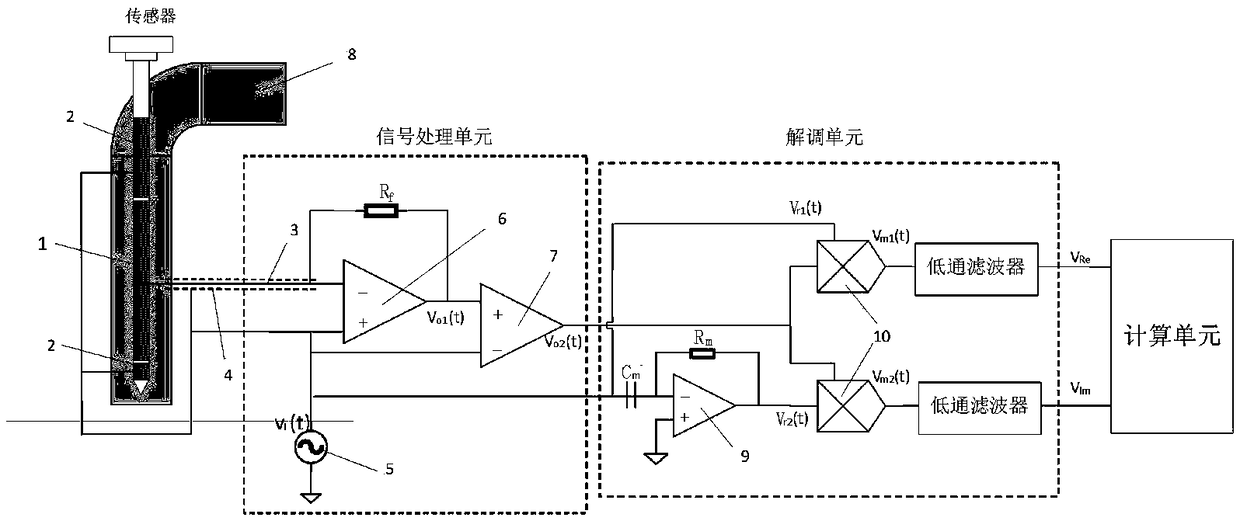

[0018] The present invention mainly comprises sensor design, signal processing unit, demodulation unit and calculation unit, and specific design is as follows:

[0019] 1. Sensor design

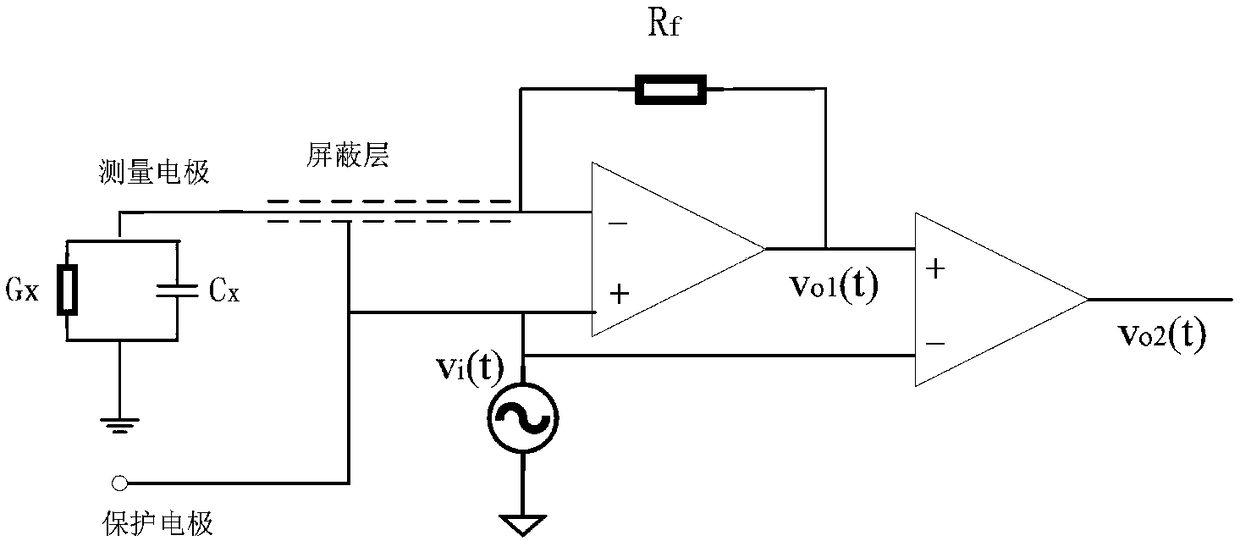

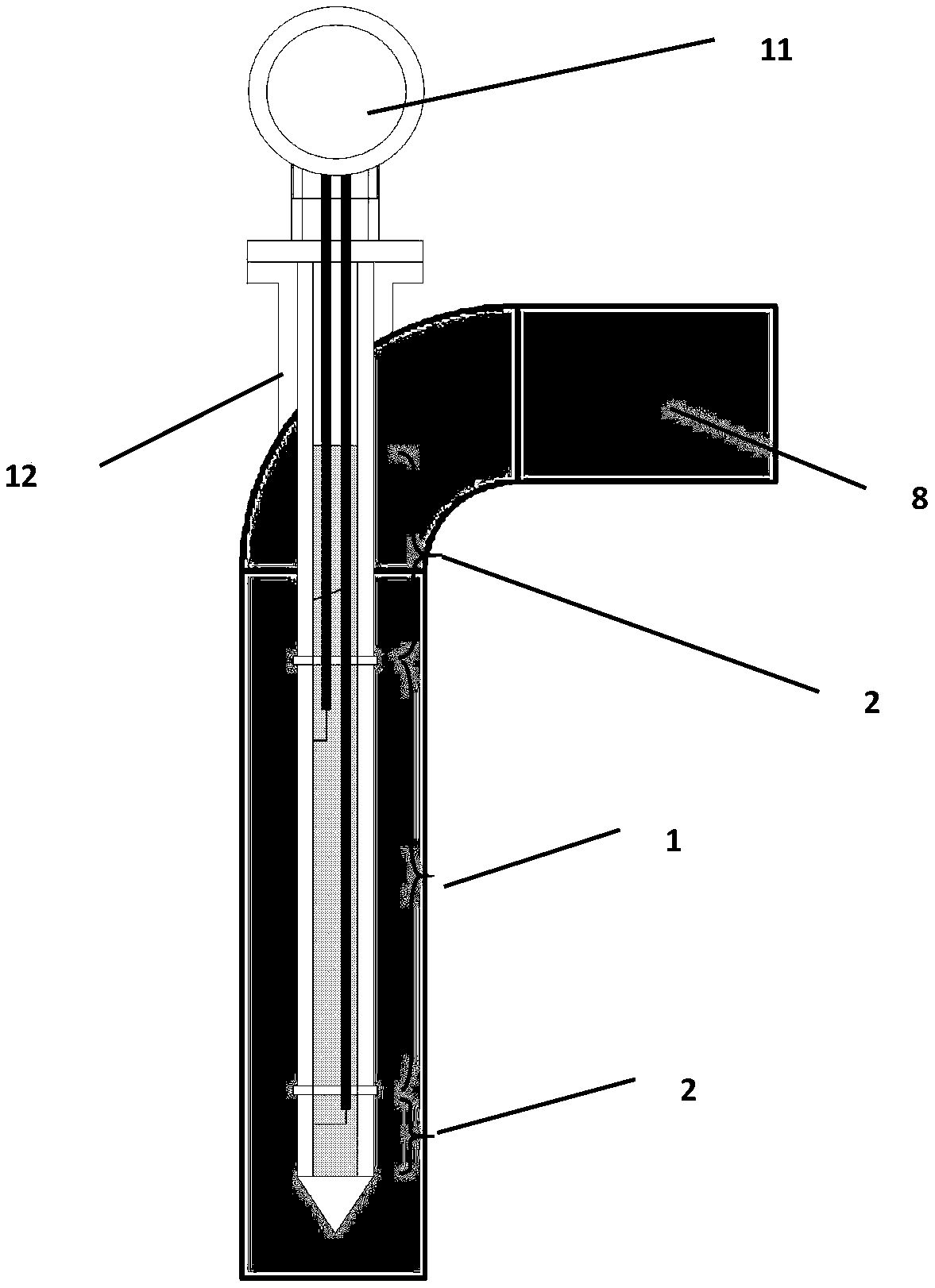

[0020] Such as figure 1 As shown, the plug-in electrical impedance sensor consists of an excitation measurement electrode in the middle and two protection electrodes above and below. Among them, the excitation and measurement share the same electrode of the sensor, and the metal pipe connected to the ground is used as the reference ground. When installing, the sensor is inserted from top to bottom along the direction of the vertical pipeline, so that the electrode is located at the axis of the vertical pipeline. The excitation measurement electrode and the protection electrode of the sensor are lead to the signal processing unit respectively, and the lead wire is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com