Hybrid modified aluminum hypophosphite and preparation method thereof

An aluminum hypophosphite and modified technology, applied in the field of flame retardants, can solve the problems of high solubility in water, low flame retardant efficiency, poor thermal stability of aluminum hypophosphite, etc., and achieve delayed decomposition, excellent flame retardant performance, and thermal stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of hybrid modified aluminum hypophosphite, the steps are as follows:

[0036] 1) Mix melamine, aluminum hypophosphite, graphite-like carbon nitride and water evenly and stir at 90°C for 0.5 hours;

[0037] 2) keep the temperature constant, add cyanuric acid to the system of step 1) and react for 0.5 hours;

[0038] 3) keep the temperature constant, add silicone resin to the system of step 2) and react for 0.5 hours;

[0039] 4) After cooling to room temperature, filter, dry and pulverize to obtain hybrid modified aluminum hypophosphite;

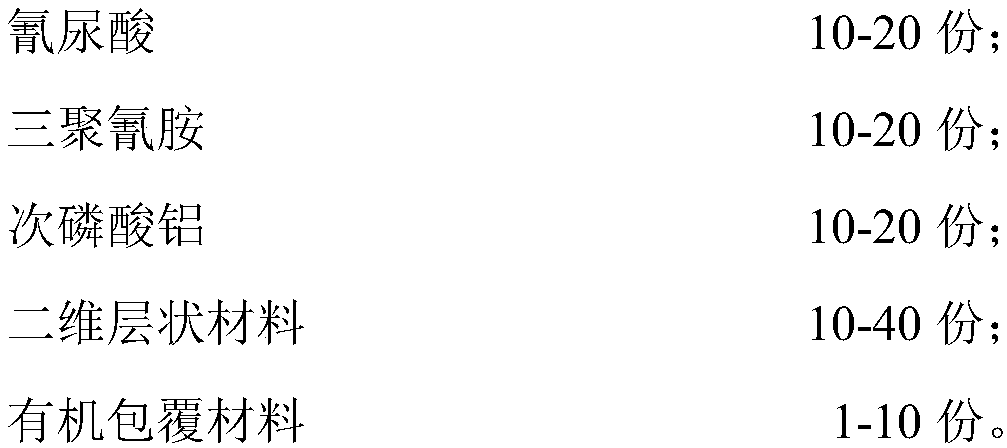

[0040] In parts by weight, the addition of each reactant is as follows:

[0041]

[0042]

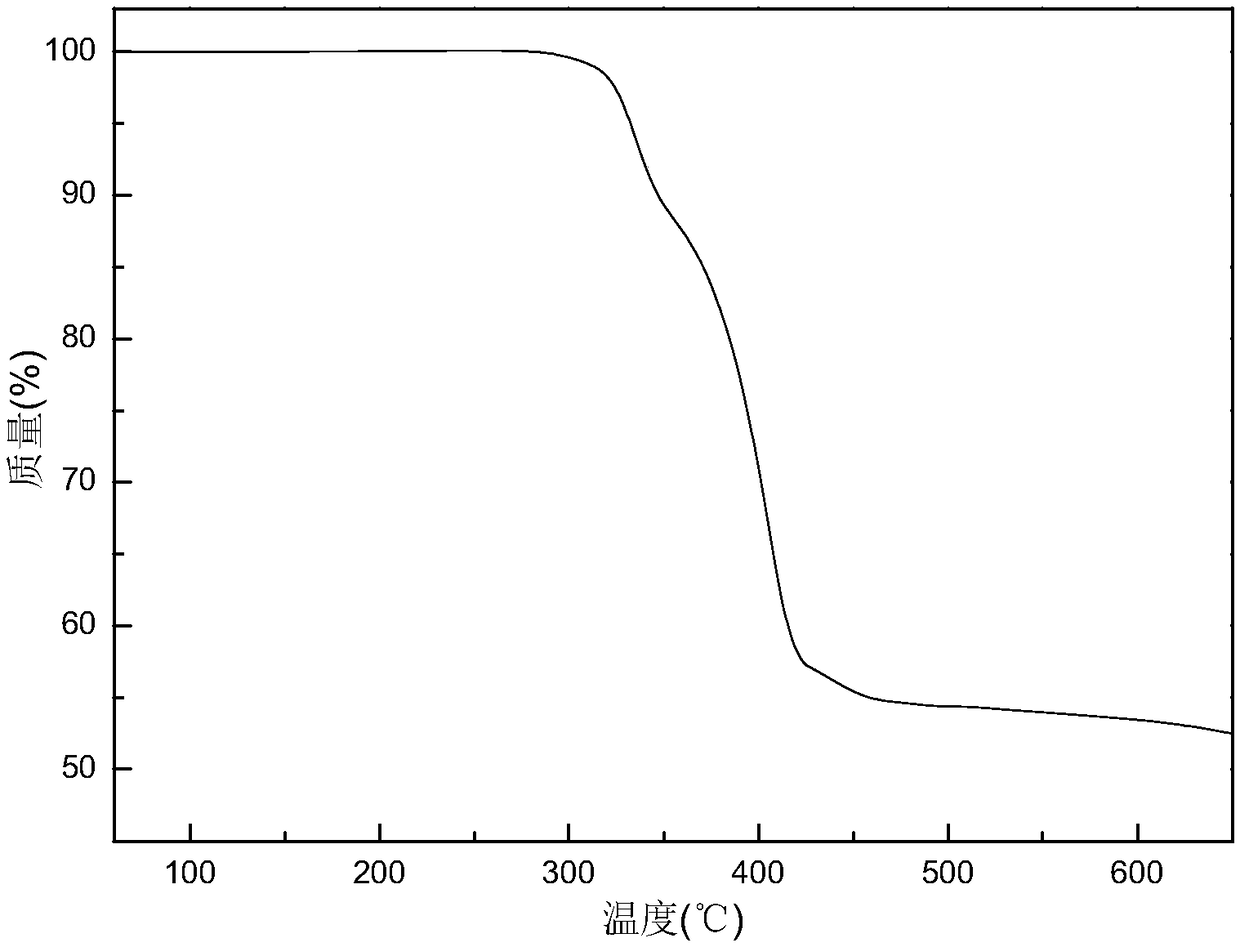

[0043] The final hybrid modified aluminum hypophosphite is composed of aluminum hypophosphite and the coating layer on its surface. The coating layer has a three-layer structure, which are melamine cyanurate layer and graphite-like nitride layer on both sides. Carbon layer and silicone resin layer; its temperature...

Embodiment 2

[0050] The preparation method of hybrid modified aluminum hypophosphite, the steps are as follows:

[0051] 1) Mix cyanuric acid, aluminum hypophosphite, graphene and methanol evenly and stir for 4 hours at a temperature of 60° C.;

[0052] 2) keep the temperature constant, add melamine to the system of step 1) and react for 2 hours;

[0053] 3) keep the temperature constant, add silicone resin to the system of step 2) and react for 4 hours;

[0054] 4) After cooling to room temperature, filter, dry and pulverize to obtain hybrid modified aluminum hypophosphite;

[0055] In parts by weight, the addition of each reactant is as follows:

[0056]

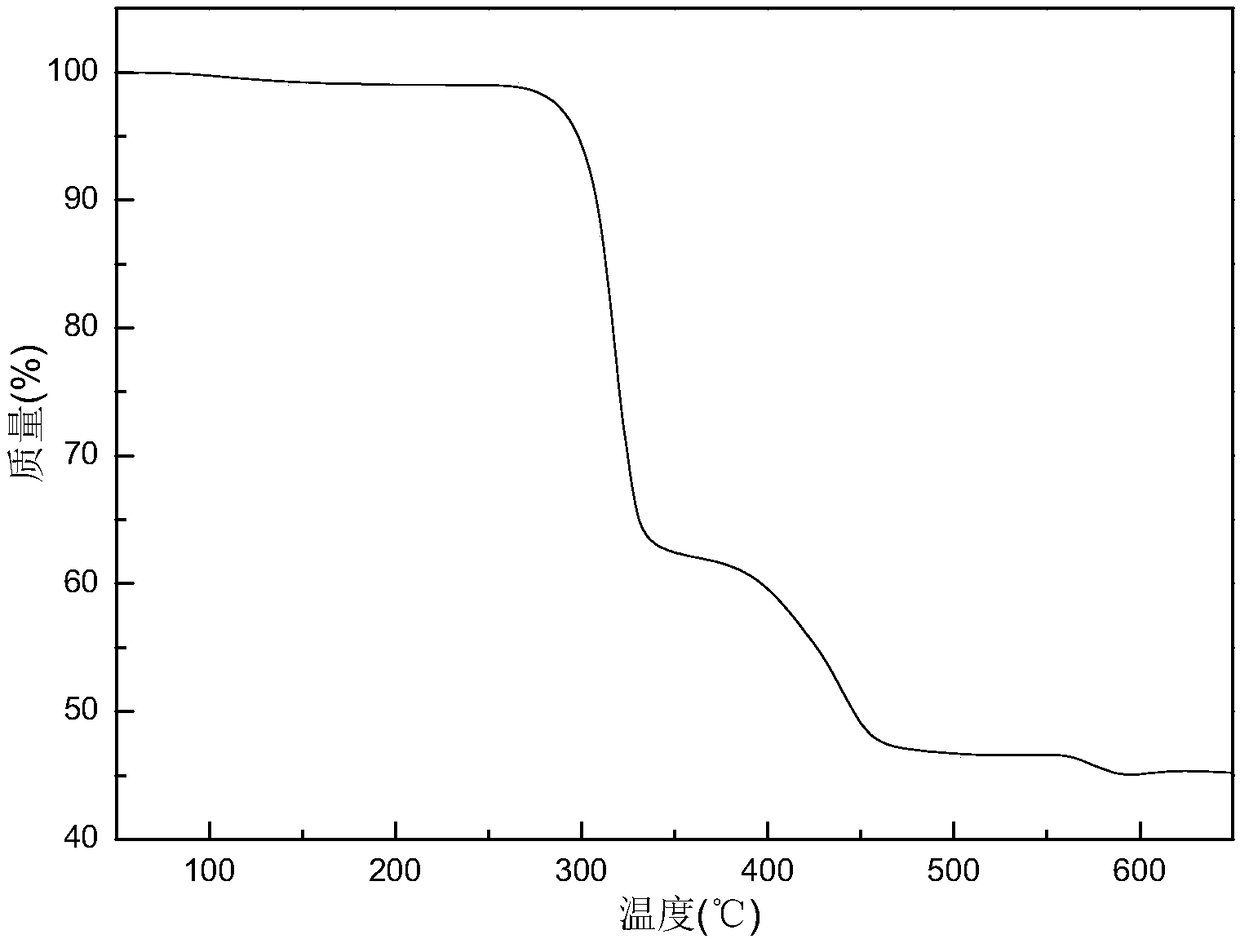

[0057] The final hybrid modified aluminum hypophosphite is composed of aluminum hypophosphite and the coating layer on its surface. The coating layer has a three-layer structure, which is a melamine cyanurate layer and a graphene layer on both sides of it. Silicone resin layer; its temperature is 305°C when the thermal weight los...

Embodiment 3

[0059] The preparation method of hybrid modified aluminum hypophosphite, the steps are as follows:

[0060] 1) Mix melamine, aluminum hypophosphite, montmorillonite and ethanol evenly and stir for 2 hours at a temperature of 50° C.;

[0061] 2) keep the temperature constant, add cyanuric acid to the system of step 1) and react for 4 hours;

[0062] 3) keep the temperature constant, add silicon coupling agent KH550 to the system of step 2) and react for 0.5 hours;

[0063] 4) After cooling to room temperature, filter, dry and pulverize to obtain hybrid modified aluminum hypophosphite;

[0064] In parts by weight, the addition of each reactant is as follows:

[0065]

[0066] The final hybrid modified aluminum hypophosphite is composed of aluminum hypophosphite and the coating layer on its surface. The coating layer has a three-layer structure, namely a melamine cyanurate layer and a montmorillonite layer on both sides of it. and silicon coupling agent KH550 layer; its tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com