Brewing method for increasing ethyl lactate content and decreasing fusel oil content in rice-flavor liquor

A technology of rice-flavored and white wine, applied in the direction of microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc., can solve the problems of not increasing ethyl lactate, not suitable for mass production of base wine, etc., and achieve wine production No reduction in efficiency, low cost, and the effect of reducing the content of fusel oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

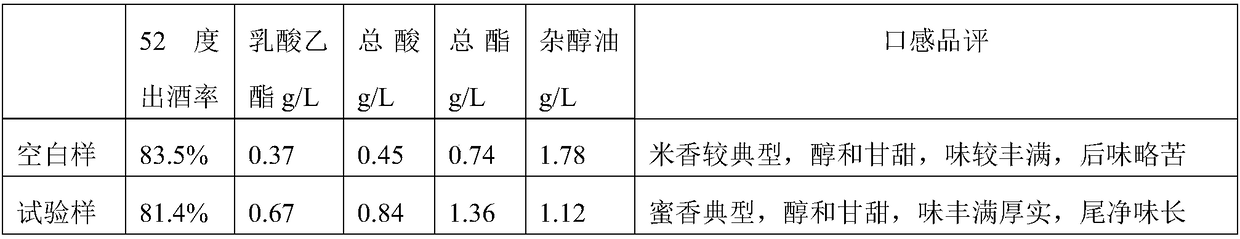

Embodiment 1

[0032] A brewing method of rice-flavored liquor, comprising the following steps:

[0033] (1) After washing the rice, add 1.5 times the volume of fermented water, soak it anaerobically at 20°C for 5 days, separate the rice from the soaking water to obtain rice milk water rich in lactic acid bacteria;

[0034] (2) After the rice is boiled and cooled to 30°C by blowing air, add 1.2% mixed koji made by mixing Rhizopus oryzae bran koji and small koji in a ratio of 1:2, stir evenly and put it in the saccharification tank for saccharification;

[0035] (3) After 16 hours of saccharification, air is introduced from the bottom of the saccharification tank, and the ventilation volume is 0.1m 3 / m 3 .min, ventilation time is 12 hours;

[0036] (4) Add 105% double volume of fermented water, 10% rice milk water, 0.05% Azomet acid protease and 0.2% Suhong GAⅡ acid-resistant glucoamylase to the saccharified fermented grains, mix evenly and pump into a large tank for fermentation Fermenta...

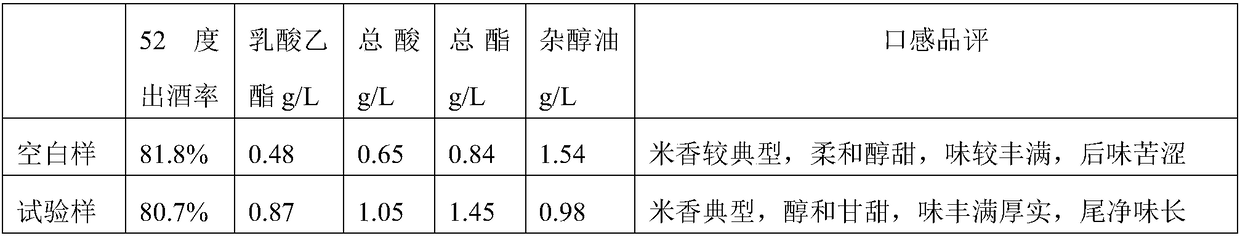

Embodiment 2

[0042] A brewing method of rice-flavored liquor, comprising the following steps:

[0043] (1) After washing the rice, add 1.8 times the volume of fermented water, soak it anaerobically at 25°C for 5 days, separate the rice from the soaking water to obtain rice milk water rich in lactic acid bacteria;

[0044] (2) After the rice is boiled and cooled to 30°C by blowing air, add 1.2% of the mixed koji made by mixing Rhizopus bran koji and small koji at a ratio of 1:3, stir evenly and put it in the saccharification tank for saccharification;

[0045] (3) After 16 hours of saccharification, air is introduced from the bottom of the saccharification tank, and the ventilation volume is 0.2m 3 / m 3 .min, ventilation time is 16 hours;

[0046] (4) Add 105% double volume of fermented water, 10% rice milk water, 0.05% Azomet acid protease and 0.2% Suhong GAⅡ acid-resistant glucoamylase to the saccharified fermented grains, mix evenly and pump into a large tank for fermentation Fermenta...

Embodiment 3

[0052] A brewing method of rice-flavored liquor, comprising the following steps:

[0053] (1) After washing the rice, add 1.8 times the volume of fermented water, soak it anaerobically at 25°C for 5 days, separate the rice from the soaking water to obtain rice milk water rich in lactic acid bacteria;

[0054] (2) After the rice is boiled, it is cooled to 30°C by blowing air, and 1.2% of the mixed koji obtained by mixing Rhizopus bran koji and Xiaokoji at a ratio of 1:3 is added, stirred evenly, and placed in a saccharification tank for saccharification;

[0055] (3) After 18 hours of saccharification, air is introduced from the bottom of the saccharification tank, and the ventilation volume is 0.3m 3 / m 3 .min, ventilation time is 18 hours;

[0056] (4) Add 105% double-volume fermented water, 10% rice milk water, 0.05% Azomet acid protease and 0.3% Suhong GAⅡ acid-resistant glucoamylase to the saccharified fermented grains, mix evenly and pump into a large tank for fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com