Low-loss electrolytic capacitor paper and preparation method thereof

An electrolytic capacitor paper, low loss technology, applied in pulp beating method, special paper, paper and other directions, can solve problems such as low cost and low ESR value, achieve significant market prospects and practical significance, reduce leakage current, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

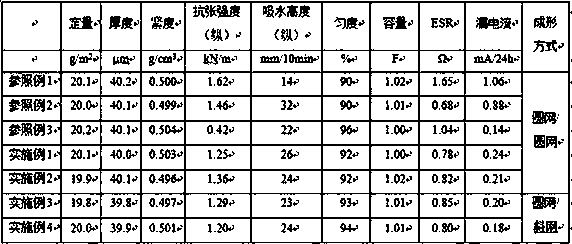

Examples

example 2

[0032] After the asparagus pulp is decomposed, it is washed with sulfuric acid solution, the pH of the washing solution is 2, the washing time is 60min, the washing concentration of the slurry is 6%, and after washing, it is rinsed with deionized water until the pH of the rinsing solution is 6~ 8. After rinsing is completed, the slurry is mixed and beaten, the beating concentration is 4%, and the beating degree is 80 ° SR, after beating, it is configured into a mixed slurry with a mass concentration of 2%, and the mixed slurry is wet-formed through a rotary screen / rotary screen, with a forming concentration of 0.08%, and then squeezed, dried, calendered, rolled, and separated Cutting to obtain low-loss electrolytic capacitor paper, paper detection quantitative, thickness, tightness, longitudinal tensile strength, water absorption height, uniformity and other indicators, made into capacitor detection capacity, internal resistance, leakage current and other indicators.

[0033]...

Embodiment 1

[0036] Mix pineapple leaf pulp, asparagus pulp, and Achnatherum splendens pulp evenly. The dry mass percentages of the three kinds of pulp are 20%, 70%, and 10% respectively. After the pulp is decomposed, it is washed with sulfuric acid solution. The pH of the washing solution is 2. The washing time is 60 minutes, the slurry washing concentration is 6%, and the deionized water is used for rinsing after washing until the pH of the rinsing solution is 6-8. After rinsing is completed, the slurry is mixed and beaten, the beating concentration is 4%, and the beating degree is 80 ° SR, after beating, it is configured into a mixed slurry with a mass concentration of 2%, and the mixed slurry is wet-formed through a rotary screen / rotary screen, with a forming concentration of 0.08%, and then squeezed, dried, calendered, rolled, and separated Cutting to obtain low-loss electrolytic capacitor paper, paper detection quantitative, thickness, tightness, longitudinal tensile strength, water ...

Embodiment 2

[0038] Mix the pineapple leaf pulp, asparagus pulp, and Achnatherum splendens pulp evenly. The dry mass percentages of the three kinds of pulp are 30%, 60%, and 10% respectively. After the pulp is decomposed, it is washed with sulfuric acid solution. The washing time is 60 minutes, the slurry washing concentration is 6%, and the deionized water is used for rinsing after washing until the pH of the rinsing solution is 6-8. After the rinsing is completed, the slurry is mixed and beaten, the beating concentration is 4%, and the beating degree is 85 ° SR, after beating, it is configured into a mixed slurry with a mass concentration of 2%, and the mixed slurry is wet-formed through a rotary screen / rotary screen, with a forming concentration of 0.08%, and then squeezed, dried, calendered, rolled, and separated Cutting to obtain low-loss electrolytic capacitor paper, paper detection quantitative, thickness, tightness, longitudinal tensile strength, water absorption height, uniformity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com