Drilling buffering adjustable support for mining

An adjustable drilling platform technology, which is applied in the direction of drilling equipment, earthwork drilling, support devices, etc., can solve the problems of unfixed support, potential safety hazards, and inconvenient adjustment of positions, etc., and achieves simple structure, convenient and reliable use , to avoid the effect of positioning offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

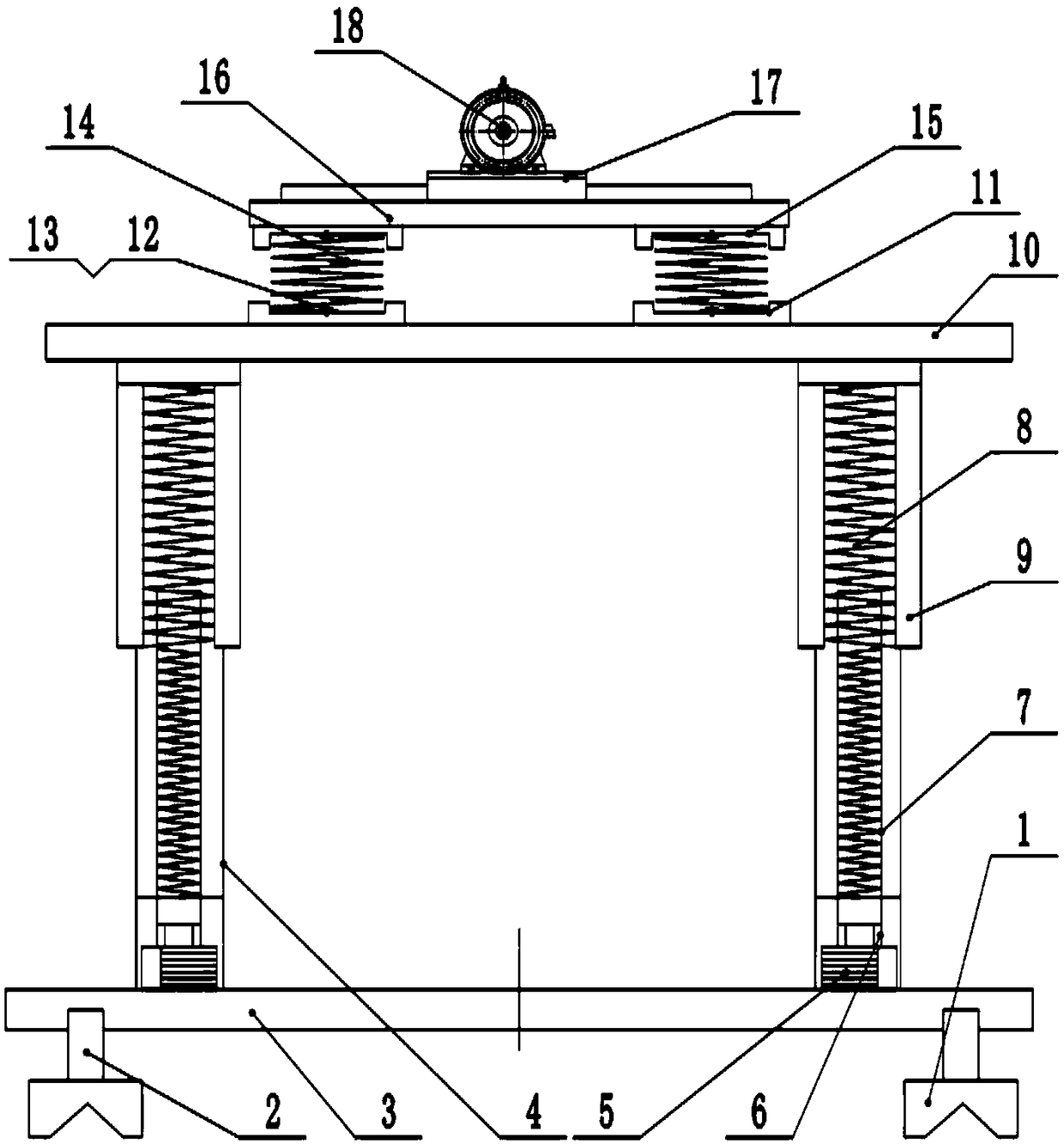

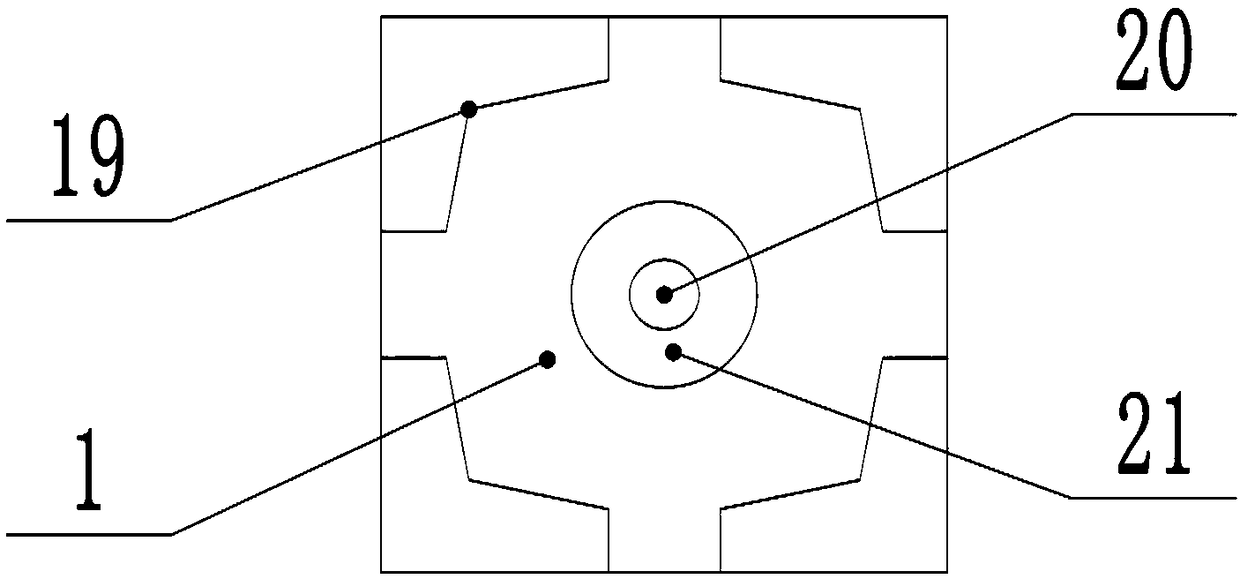

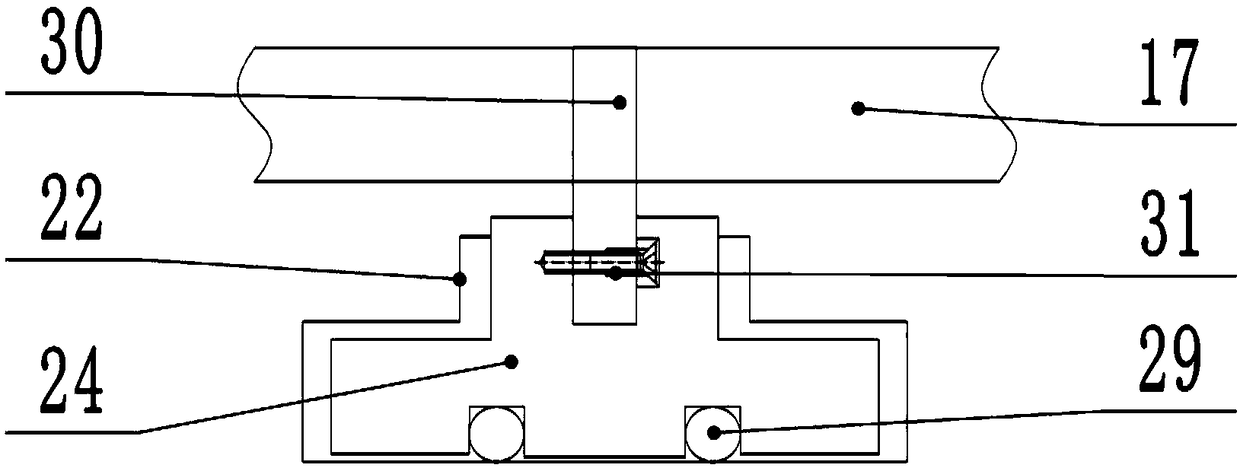

[0021] see figure 1 , a drilling buffer adjustable support for mining, including: a leg 1, a leg connecting rod 2, an upper fixed plate 10 and a drill bit 28, the leg 1 is placed in the mine and used, such as figure 2 As shown, the bottom of the support foot 1 is hollowed out in the middle, and corner brackets 19 are arranged around it, and the corner brackets 19 are structures with a large upper part and a smaller lower part to improve stability. The lower end of the corner bracket 19 is provided with a raised anti-slip block , after quenching treatment, the hardness reaches HRC=55-65, anti-slip and wear-resistant, the bottom of the support foot 1 is provided with a chassis installation hole 20, and the bolt passes through the chassis installation hole 20 to fix the support foot 1 to the lower end of the connection rod 2 of the support foot. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com