Analysis method for simultaneously detecting iodoacetic acid and aromatic iodide disinfection by-product in water

A technology of disinfection by-products and analytical methods, applied in the field of environmental analytical chemistry, can solve the problems of high detection limit and low recovery rate of iodoacetic acid, and achieves the effects of easy operation and less reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

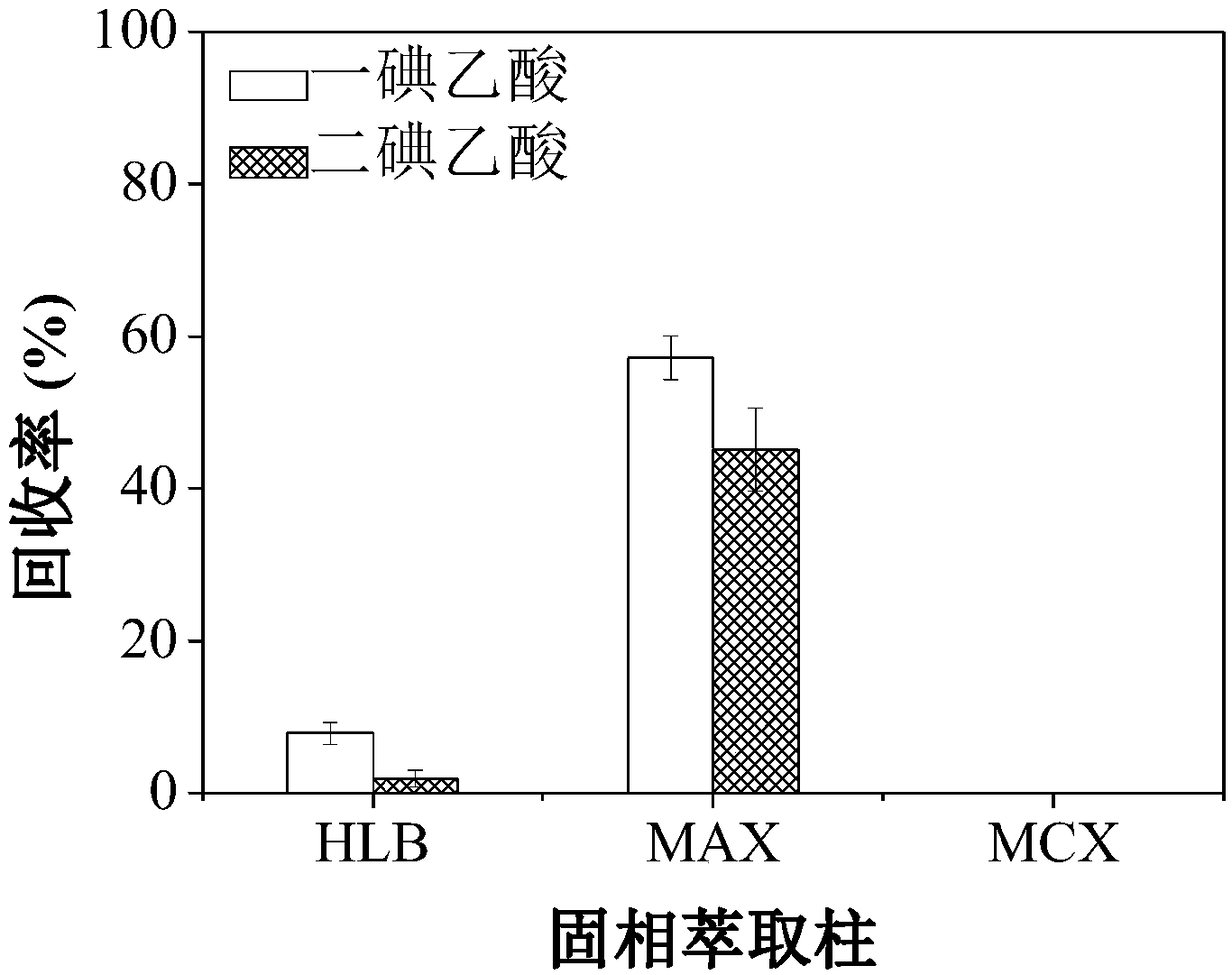

[0038] Select a solid phase extraction column, the steps are: respectively pass 1L of water sample (100ng / L) containing monoiodoacetic acid and diiodoacetic acid through three different solid phase extraction columns, namely Oasis HLB column, Oasis MAX column, and Oasis MCX column. Elute with 6 mL of methanol solution containing 2% formic acid, blow the eluent to 0.2 mL with nitrogen, and add 0.3 mL of acetonitrile. Before detection, 0.5 mL of ultrapure water was added to the sample and filtered through a 0.45 μm filter membrane; the sample was detected by HPLC-MS / MS, and then the recovery rate was calculated. The result is as figure 1 As shown, the recoveries obtained by treatment with Oasis MAX column are relatively high, the recovery rate of monoiodoacetic acid is 57%, and the recovery rate of diiodoacetic acid is 45%. The recoveries obtained with both Oasis HLB and Oasis MCX columns were less than 10%. Therefore, the most suitable solid-phase extraction column for iodoa...

Embodiment 2

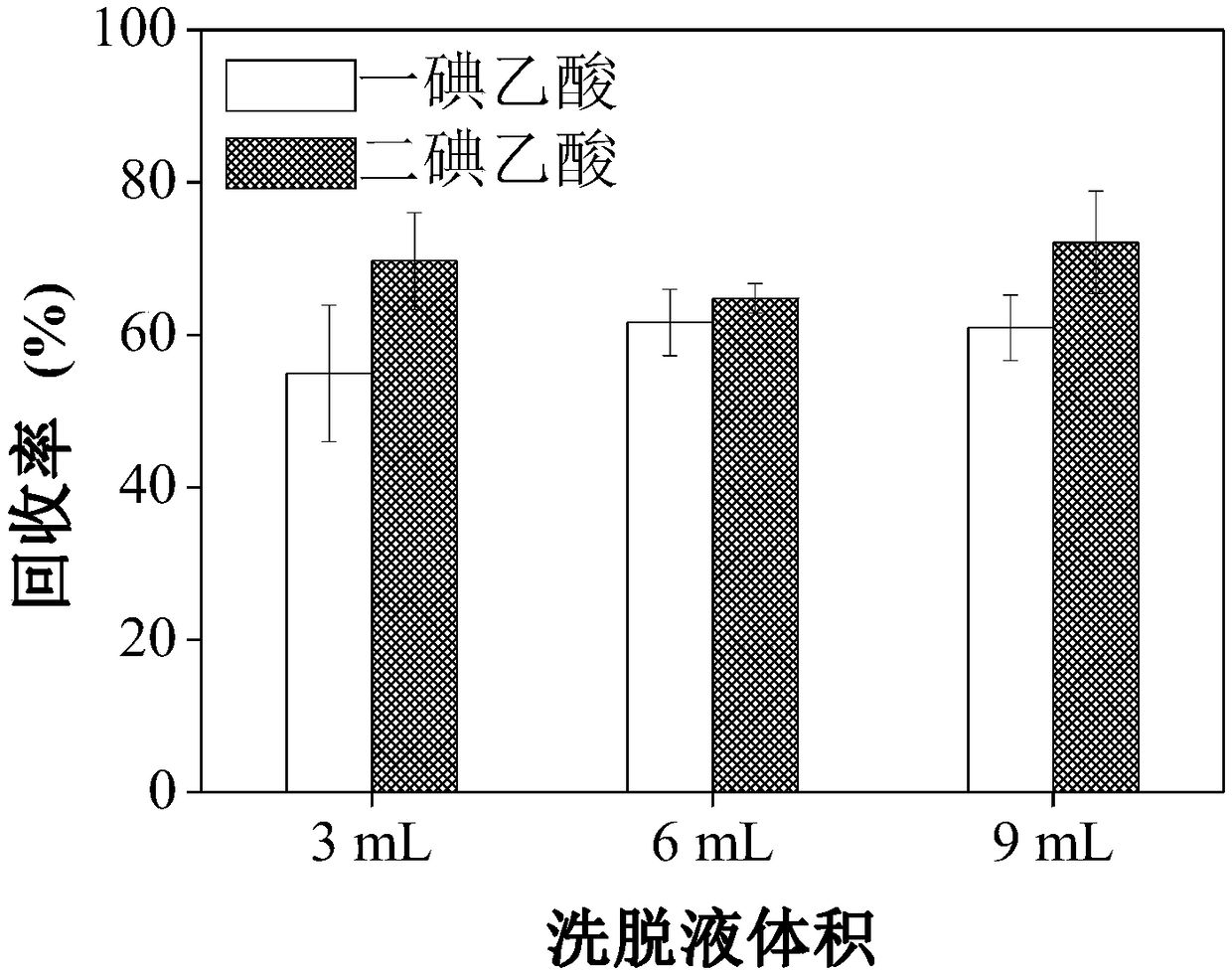

[0040]To optimize the eluent volume, the steps are as follows: pass 1L of water sample (100ng / L) containing monoiodoacetic acid and diiodoacetic acid through the OasisMAX solid phase extraction column. Use 3 mL, 6 mL, and 9 mL of methanol solution containing 2% formic acid to elute respectively, blow the eluent to 0.2 mL with nitrogen, and add 0.3 mL of acetonitrile. Before detection, 0.5 mL of ultrapure water was added to the sample and filtered through a 0.45 μm filter membrane; the sample was detected by HPLC-MS / MS, and then the recovery rate was calculated. The result is as figure 2 As shown, the results show that the eluent volume has little effect on the recovery rate, so in order to reduce reagent consumption, 3mL is selected as the optimal eluent volume.

Embodiment 3

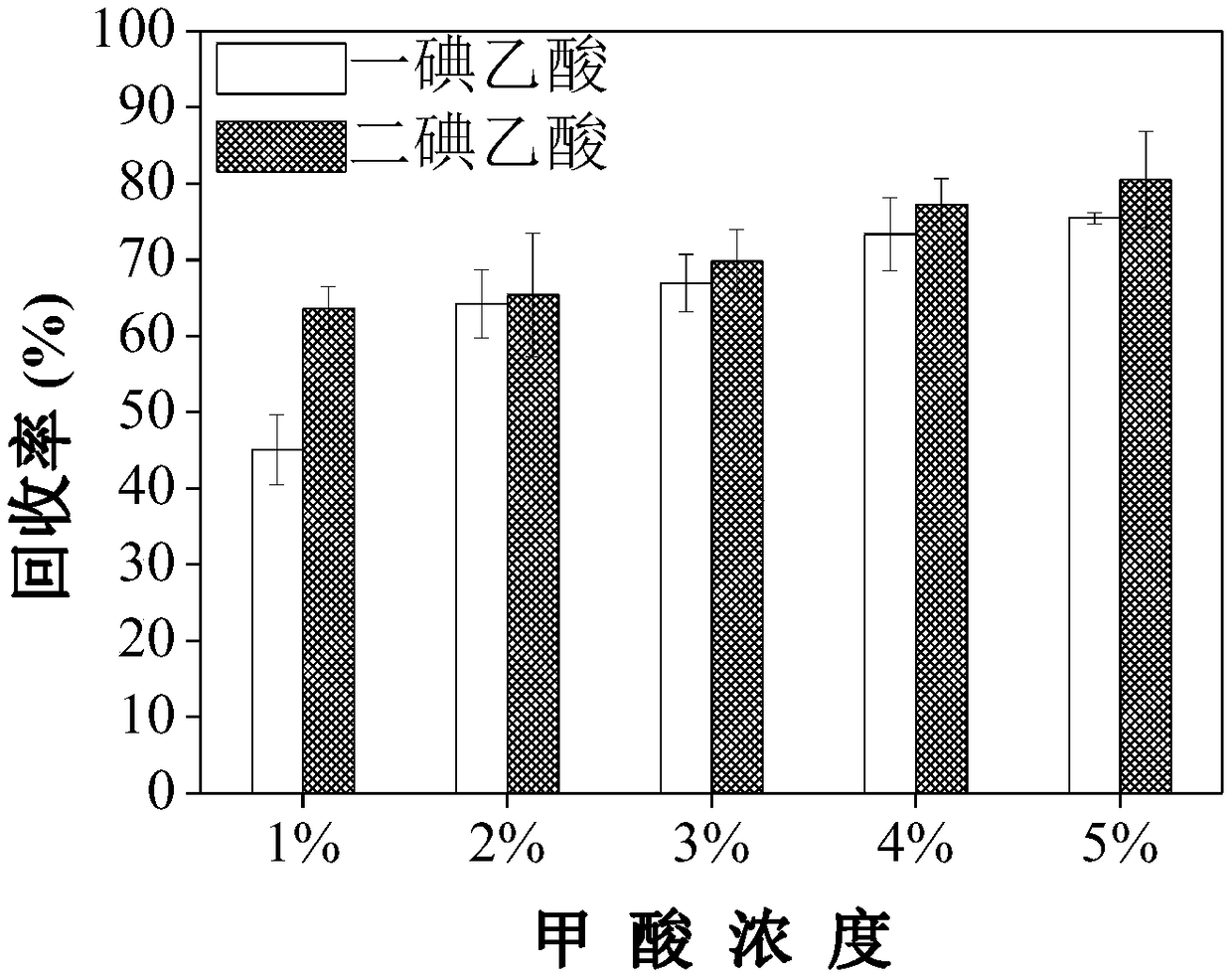

[0042] To optimize the eluent components, the steps are as follows: pass 1L of water sample (100ng / L) containing monoiodoacetic acid and diiodoacetic acid through the OasisMAX solid phase extraction column. Elute with 3 mL of eluent (1–5%) containing different concentrations of formic acid, blow the eluent to 0.2 mL with nitrogen, and add 0.3 mL of acetonitrile. Before detection, 0.5 mL of ultrapure water was added to the sample and filtered through a 0.45 μm filter membrane; the sample was detected by HPLC-MS / MS, and then the recovery rate was calculated. The result is as image 3 As shown, with the formic acid concentration increasing from 1% to 4%, the recovery rate of iodoacetic acid increases continuously; when the formic acid concentration increases from 4% to 5%, the recovery rate of iodoacetic acid has no significant change. Therefore, the optimal formic acid concentration was selected to be 4% according to the recovery rate. Thus, the optimal elution condition was o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com