Design method and device of two-dimensional body holographic grating laser

A volume holographic grating and laser technology, which is applied in lasers, laser parts, phonon exciters, etc., can solve the problems of laser power increase and beam quality nonlinear decline, and achieve simple structure and keep the fundamental transverse mode unchanged Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

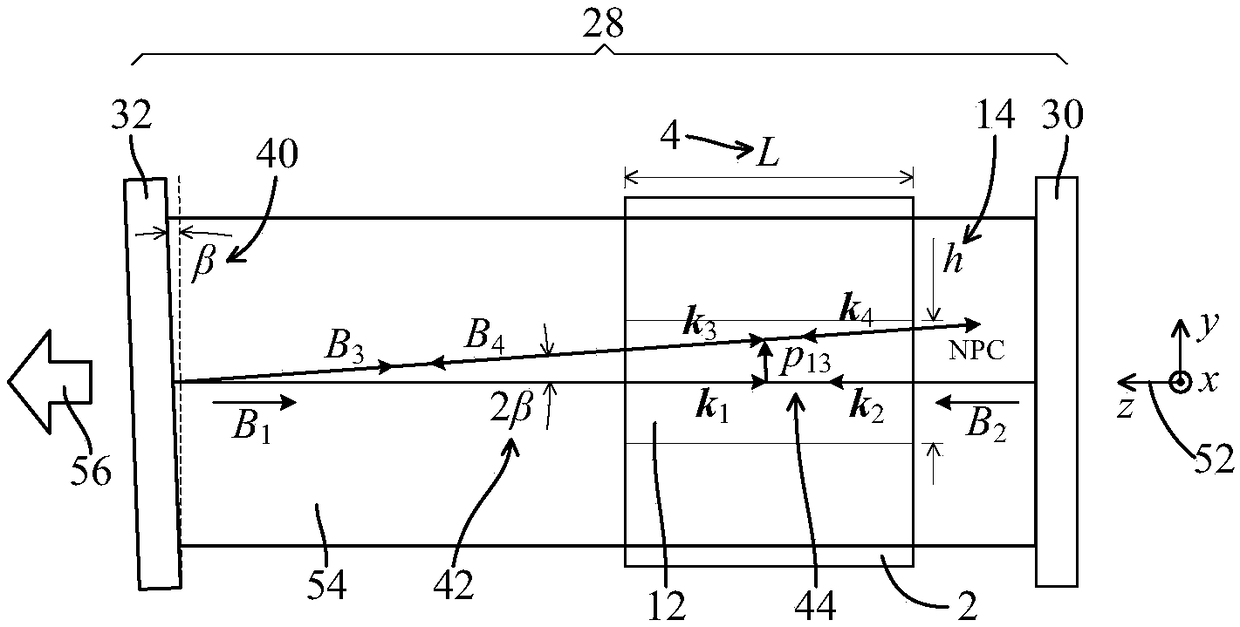

Embodiment 1A

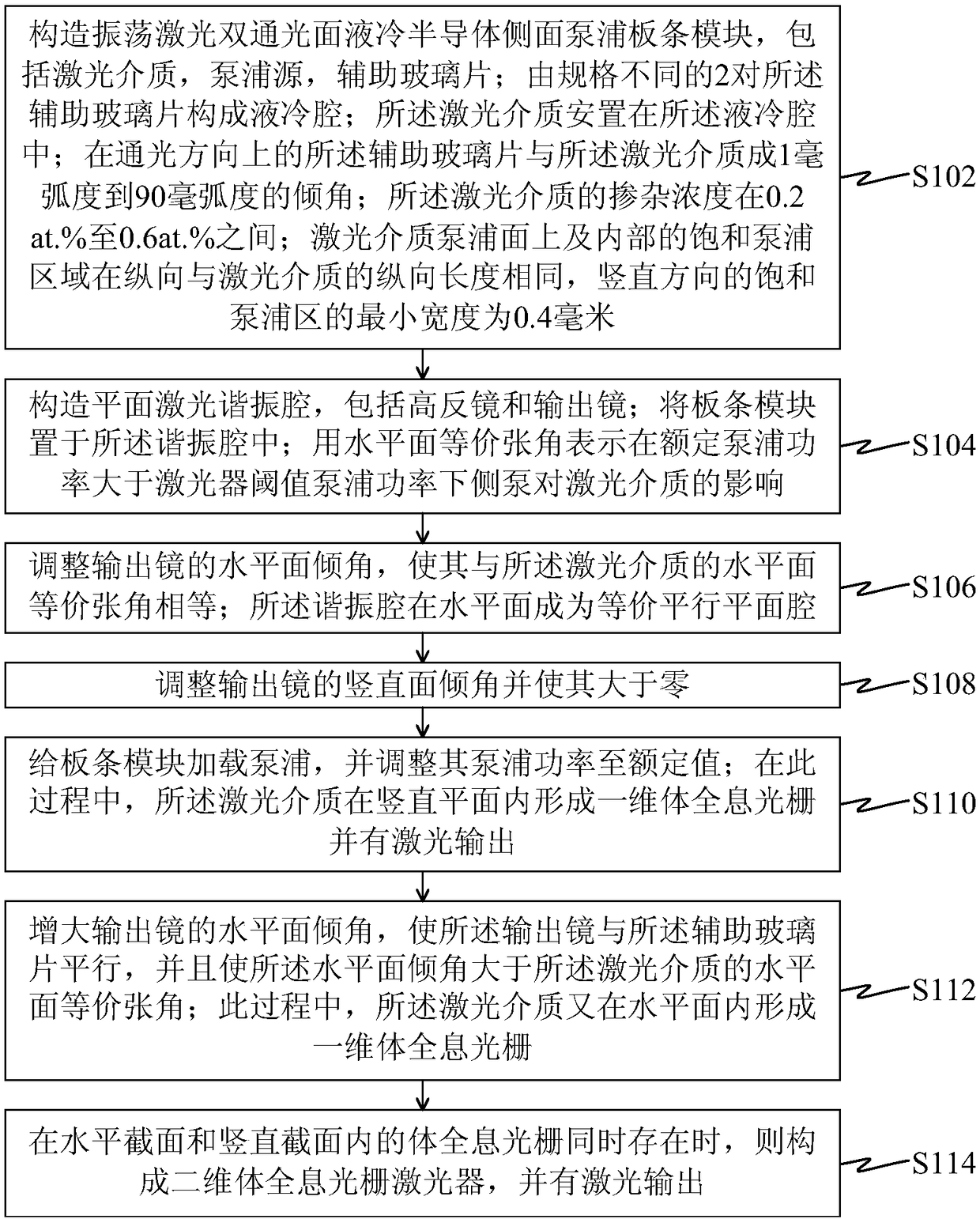

[0044] figure 2 It is a horizontal cross-sectional schematic diagram of a volume holographic grating laser. In the X-Z horizontal section, the laser includes a laser resonant cavity 28 , a laser medium 2 , and a semiconductor laser pump source 8 . The semiconductor laser pumping source 8 vertically saturates and pumps the laser medium 2 sideways, and the pumping direction 10 of the pumping source 8 in the horizontal plane is perpendicular to the optical axis 52 of the laser. The laser resonant cavity 28 is a non-parallel planar cavity, including a high reflection mirror 30 and an output mirror 32 . A cuboid-shaped slab laser medium 2 is arranged in the laser resonator 28 , and its longitudinal length 4 along the optical axis 52 is smaller than its transverse length. The doping concentration of the laser medium 2 is between 0.2 at.% and 0.6 at.%. The two oscillating laser light-transmitting surfaces of the laser medium 2 are cooled with flowing coolant. The temperature gra...

Embodiment 1B

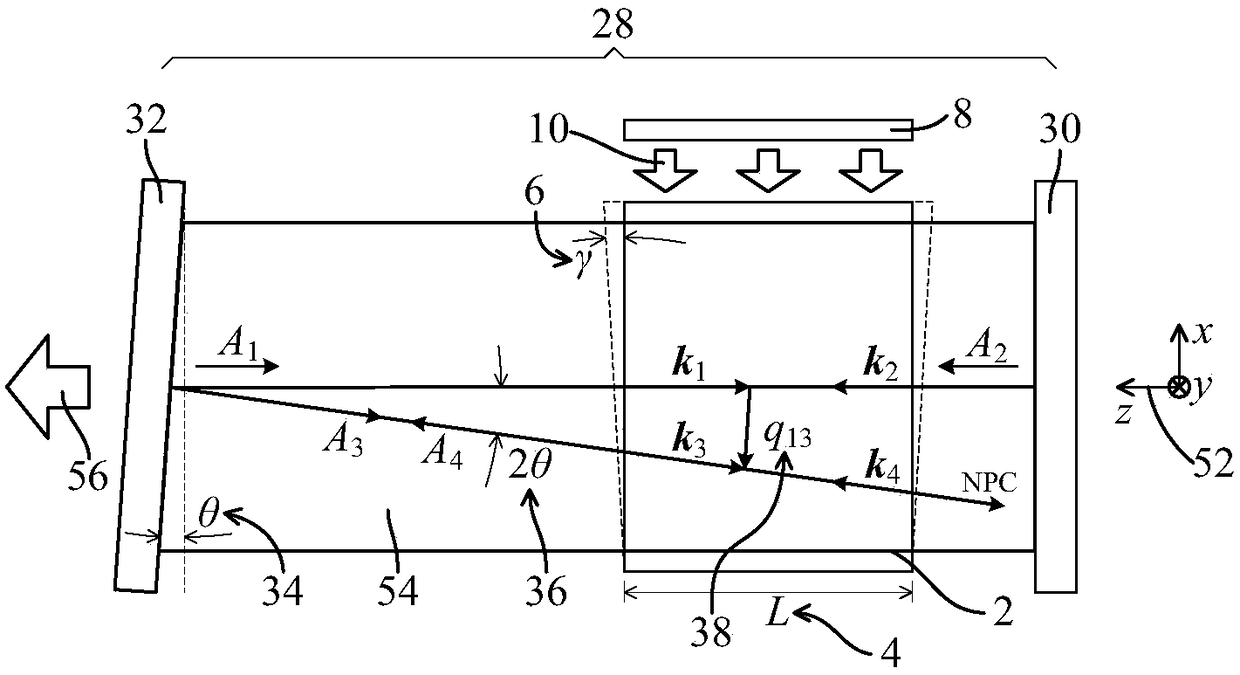

[0047] image 3 A schematic diagram of a vertical cross-section of a volume holographic grating laser. In the Y-Z vertical section, the laser and the structure in the horizontal section figure 2 basically the same.

[0048] The laser includes a laser resonator 28 , a laser medium 2 , and a semiconductor laser pump source 8 . The pumping direction 10 of the pumping source 8 in the vertical section is perpendicular to the inward plane of the paper, that is, the vertical optical axis 52 . The saturated pumping region 12 on the pumping surface and inside of the laser medium 2 is the same as the longitudinal length 4 of the laser medium 2 in the longitudinal direction, and the minimum width 14 of the saturated pumping region 12 in the vertical direction is 0.4 mm. The laser resonant cavity 28 uses two plane mirrors, including a high reflection mirror 30 and an output mirror 32, and the initial state is a parallel plane cavity. A cuboid-shaped slab laser medium 2 is arranged in...

Embodiment 1C

[0051] Such as figure 2 and image 3 As shown, when the volume holographic grating exists in the horizontal section and the vertical section at the same time, a two-dimensional volume holographic grating solid-state laser is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com