Preparation method of Ni@SiO2 core-shell structure catalyst and application of Ni@SiO2 core-shell catalyst in methane and carbon dioxide reforming reaction

A technology of structural catalyst and core-shell structure, applied in the fields of energy utilization and environment, can solve problems such as catalyst deactivation, and achieve the effects of good activity, simple and easy operation, and reduced catalyst cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

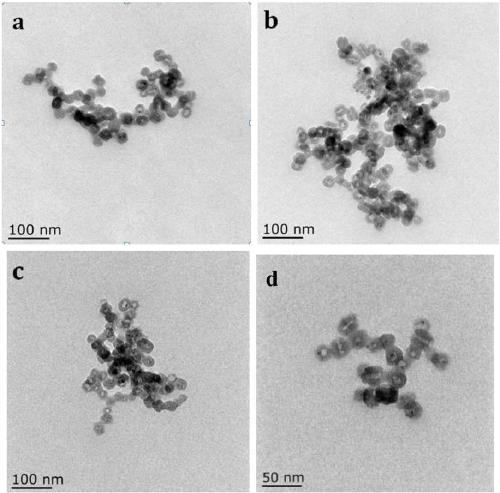

Image

Examples

Embodiment 1

[0026] a. Mix 0.005 mol of polyoxyethylene (n=20) cetyl ether with 15 ml of cyclohexane, and stir evenly in a water bath at 40° C. to form a white emulsion.

[0027] b. Add dropwise 0.5 milliliters of nickel nitrate solution with a concentration of 1 mole per liter into the white emulsion, stir evenly, and the emulsion is light green.

[0028] c. Raise the temperature of the water bath to 50 degrees, and slowly add 0.6 ml of hydrazine hydrate with a concentration of 80 percent to the solution. Seal and stir for 20 minutes. Forms a light purple emulsion.

[0029] b. Keeping the temperature constant, 2.1 ml of tetraethyl orthosilicate was slowly added dropwise to the solution, and the mixture was sealed and stirred for 40 minutes.

[0030] d. Dissolve 0.001 mole of L-lysine in 139 ml of water, take 26.2 ml of L-lysine solution and put it in a 60-degree water bath, and slowly add the solution obtained in step b to the entire solution drop by drop. Control the dropping time to ...

Embodiment 2

[0035] a. Mix 0.005 mol of polyoxyethylene (n=20) cetyl ether with 15 ml of cyclohexane, and stir evenly in a 40-degree water bath to form a white emulsion.

[0036] b. Add dropwise 0.5 mL of nickel nitrate solution with a concentration of 1 mole per liter into the white emulsion, stir evenly, and the emulsion becomes light green.

[0037] c. Raise the temperature of the water bath to 50 degrees, and slowly add 0.6 ml of hydrazine hydrate with a concentration of 80 percent to the solution. Seal and stir for 20 minutes. Forms a light purple emulsion.

[0038] d. Keeping the temperature constant, 2.1 ml of tetraethyl orthosilicate was slowly added dropwise to the solution, and the mixture was sealed and stirred for 40 minutes.

[0039] e. Dissolve 0.001 mole of L-lysine in 139 ml of water, take 26.2 ml of L-lysine solution and put it in a 60-degree water bath, and slowly add the solution obtained in step b to the entire solution drop by drop. Control the dropping time for 30 ...

Embodiment 3

[0044] a. Mix 0.005 mol of polyoxyethylene (n=20) cetyl ether with 15 ml of cyclohexane, and stir evenly in a 40-degree water bath to form a white emulsion.

[0045]b. Add dropwise 0.5 milliliters of nickel nitrate solution with a concentration of 1 mole per liter into the white emulsion, stir evenly, and the emulsion is light green.

[0046] c. Raise the temperature of the water bath to 50 degrees, and slowly add 0.6 ml of hydrazine hydrate with a concentration of 80 percent to the solution. Seal and stir for 20 minutes. Forms a light purple emulsion.

[0047] d. Keeping the temperature constant, slowly add 2.1 ml of tetraethyl orthosilicate dropwise to the solution, and stir for 40 minutes under seal.

[0048] e. Dissolve 0.001 mole of L-lysine in 139 ml of water, take 26.2 ml of L-lysine solution and put it in a 60-degree water bath, and slowly add the solution obtained in step b to the entire solution drop by drop. Control the dropping time for 30 minutes, stir evenly, ...

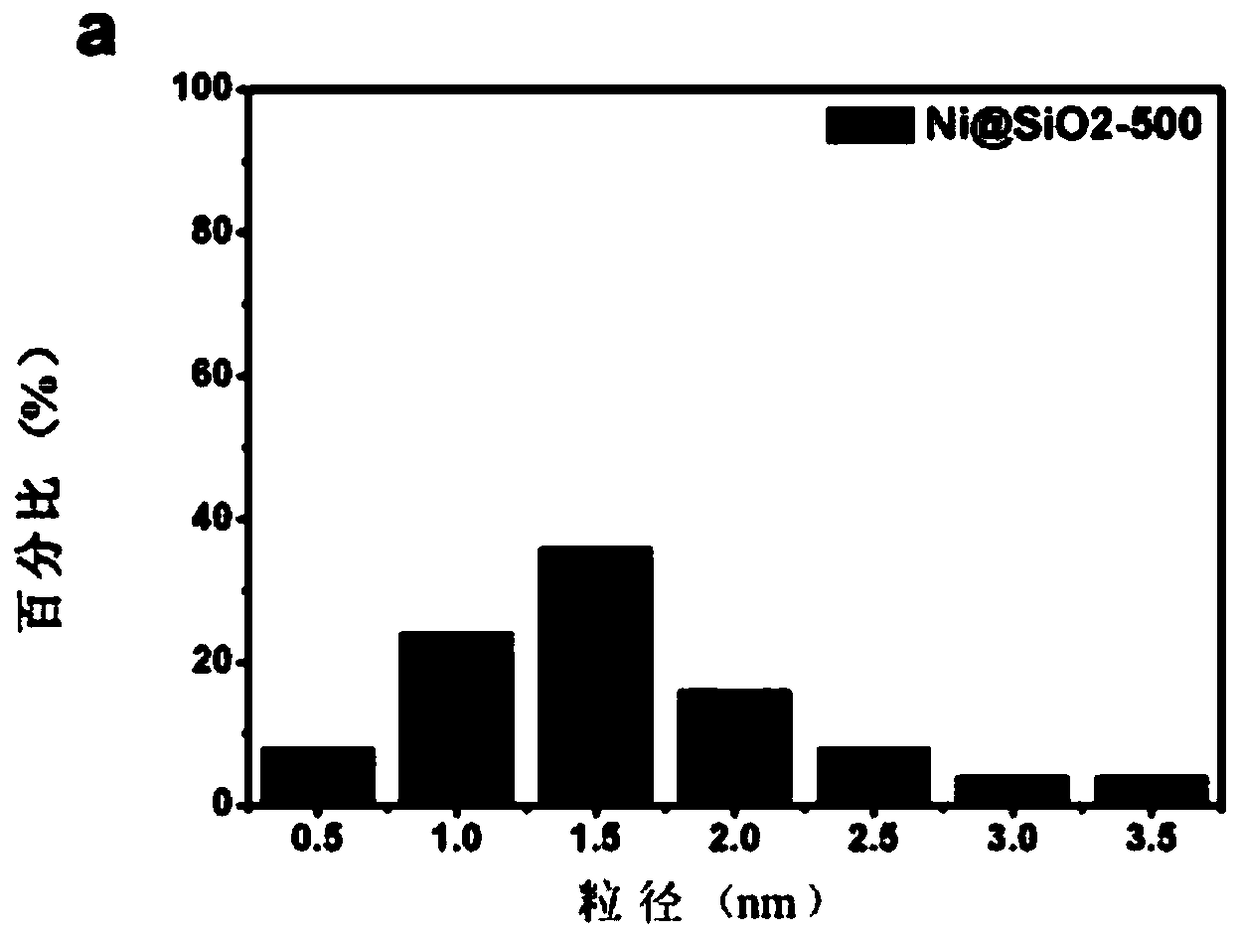

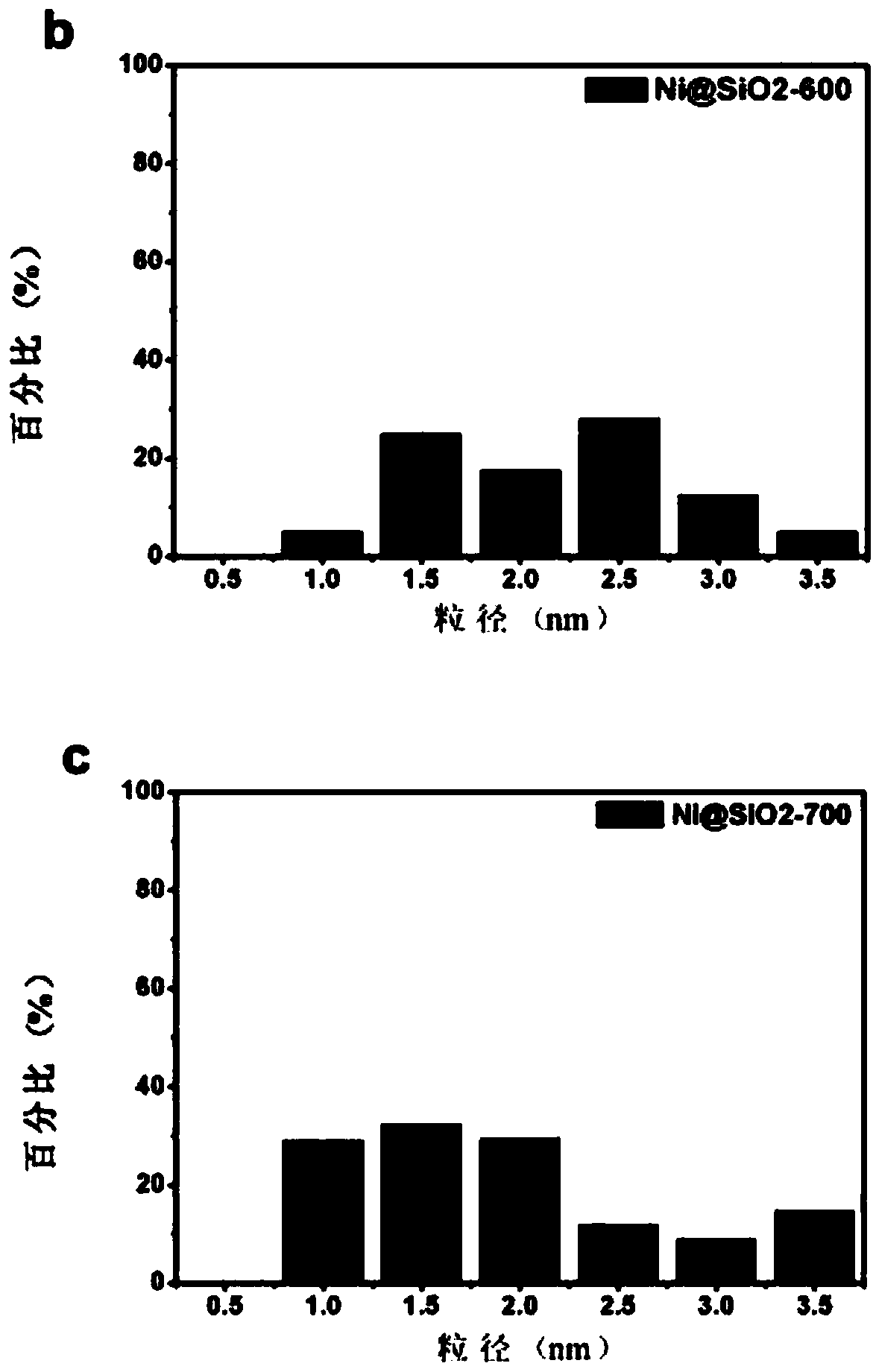

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com