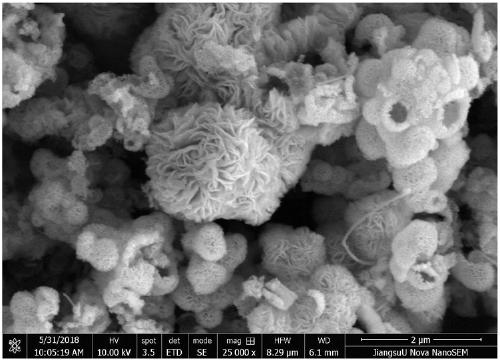

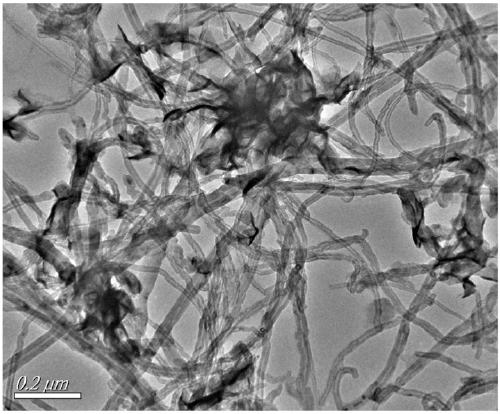

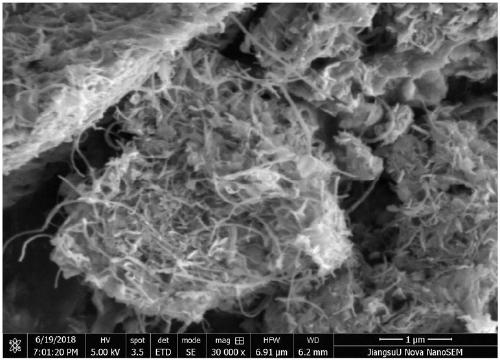

Flower-shaped molybdenum diselenide/carbon nano tube composite material as well as synthetic method and application thereof

A technology of carbon nanotubes and molybdenum diselenide, applied in chemical instruments and methods, chemical/physical processes, catalyst activation/preparation, etc., to promote the separation of electrons and holes and increase the surface contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Pour carbon nanotubes and concentrated nitric acid into the reaction kettle, wherein the ratio of carbon nanotubes and concentrated nitric acid is 20mg:100ml; the hydrothermal temperature is 100°C, and the heating time is 1 hour; collect the precipitate after the reaction, and add acetone solution , ultrasonication for 30 minutes; then wash with deionized water and alcohol for 3 times; dry; grind and set aside;

[0030] Add the carbon nanotubes processed in the above steps into the reactor, and then add Na 2 MoO 4 2H 2 O, Se powder and NaBH4 and ethanol aqueous solution, in which carbon nanotubes, Na 2 MoO 4 2H 2 O, Se powder and NaBH 4 The concentrations are 0.5g / L, 0.14mol / L, 0.49mol / L, 0.17mol / L, respectively. Wherein the aqueous ethanol solution is 40ml (alcohol: water=1:1); put into a vacuum drying oven, the holding temperature is 220°C, and the time is 24h; the precipitate is collected and treated with NaOH solution for 2 hours at 80°C, the concentration of ...

Embodiment 2

[0033] Pour carbon nanotubes and concentrated nitric acid into the reaction kettle, wherein the ratio of carbon nanotubes to concentrated nitric acid is 80mg:100ml; the hydrothermal temperature is 120°C, and the heating time is 1 hour; collect the precipitate after the reaction, and add acetone solution , ultrasonication for 60 minutes; then wash with deionized water and alcohol for 3 times; dry; grind and set aside;

[0034] Add the carbon nanotubes processed in the above steps into the reactor, and then add Na 2 MoO 4 2H 2 O, Se powder and NaBH 4 and ethanol aqueous solution, in which carbon nanotubes, Na 2 MoO 4 2H 2 O, Se powder and NaBH 4 The concentrations are 2g / L, 0.14mol / L, 0.45mol / L, 0.15mol / L, respectively. Wherein the aqueous ethanol solution is 50ml (alcohol: water = 1:1); put it into a vacuum drying oven, keep the temperature at 220°C for 24h; collect the precipitate, and treat it with NaOH solution at 80°C for 6 hours, the concentration of NaOH solution i...

Embodiment 3

[0037] Pour carbon nanotubes and concentrated nitric acid into the reaction kettle, wherein the ratio of carbon nanotubes and concentrated nitric acid is 20mg:100ml; the hydrothermal temperature is 80°C, and the heating time is 1 hour; collect the precipitate after the reaction, and add acetone solution , ultrasonication for 30 minutes; then wash with deionized water and alcohol for 3 times; dry; grind and set aside;

[0038] Add the carbon nanotubes processed in the above steps into the reactor, and then add Na 2 MoO 4 2H 2 O, Se powder and NaBH4 and ethanol aqueous solution, in which carbon nanotubes, Na 2 MoO 4 2H 2 O, Se powder and NaBH 4 The concentrations are 0.5g / L, 0.14mol / L, 0.49mol / L, 0.17mol / L, respectively. Among them, the ethanol aqueous solution is 40ml (alcohol: water = 1:1); put it into a vacuum drying oven, keep the temperature at 180°C, and the time is 24h; collect the precipitate, and treat it with NaOH solution at 80°C for 2 hours, and the concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com