Vehicle-mounted substation

A substation and vehicle-mounted technology, which is applied in the field of substations, can solve the problems of inability to pass cables smoothly and easily hang up cables in substations, and achieve the effects of excellent mechanical properties and insulation properties, light weight and strong adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

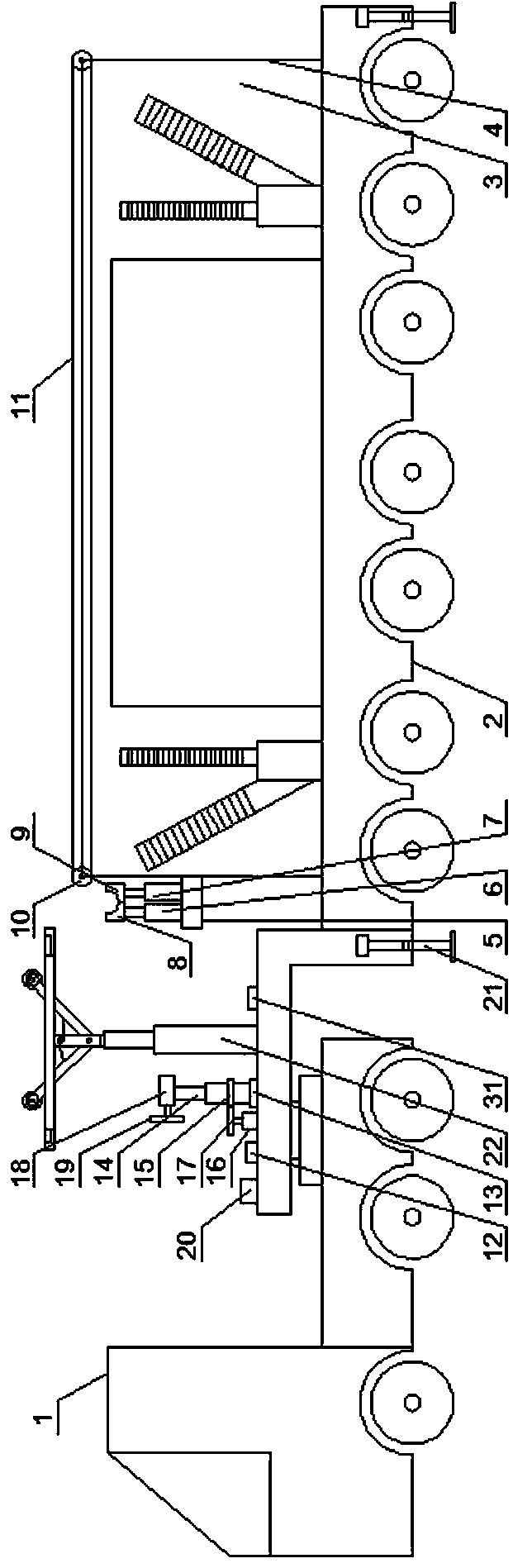

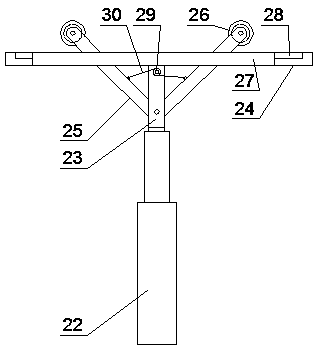

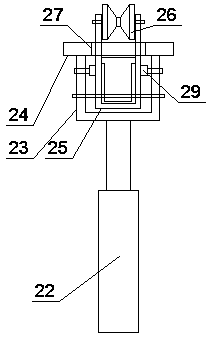

[0037] like figure 1 , figure 2 and image 3 As shown, a vehicle-mounted substation includes a tractor 1 and a trailer 2, the trailer 2 is provided with a substation body 3, the substation body 3 is covered with a protective frame 4, and the upper part of the front end of the trailer 2 is provided with a On the way, hang up the protective mechanism of the cables located above the substation body 3;

[0038] Described protective mechanism comprises the platform 5 that is arranged on the front end side of described protective frame 4, and the left automatic elevating rod 6 and the right automatic elevating rod 7 that are arranged side by side on described platform 5, are arranged on described left automatic elevating rod 6 upper ends The left top block 8 is arranged on the right top block 9 on the upper end of the right automatic lifting rod 7, and the quarter arc groove on the right side of the left top block 8 is opened on the left side of the right top block 9. The quarte...

Embodiment 2

[0050]The difference from Example 1 is that the waterproof layer contains components and their contents: 16 parts by weight of polyaniline, 2.5 parts by weight of polymethyl methacrylate, 7 parts by weight of chloroform, N,N-di 42 parts by weight of methyl formamide, 16 parts by weight of sodium silicate, 2.8 parts by weight of sodium lauryl sulfate, 8 parts by weight of nano silicon dioxide, 6 parts by weight of sodium methyl silicate, tetrachloroterephthalic acid di 3.7 parts by weight of methyl ester, 8.9 parts by weight of cinnamaldehyde, 23 parts by weight of acetone, and 48 parts by weight of deionized water.

Embodiment 3

[0052] The difference from Example 1 is that the waterproof layer contains components and their contents: 17 parts by weight of polyaniline, 3 parts by weight of polymethyl methacrylate, 7.5 parts by weight of chloroform, N,N-di 44 parts by weight of methyl formamide, 16.5 parts by weight of sodium silicate, 3 parts by weight of sodium lauryl sulfate, 9 parts by weight of nano silicon dioxide, 6.1 parts by weight of calcium stearate, dimethyl tetrachloroterephthalate 3.9 parts by weight of ester, 9 parts by weight of polyaspartic acid, 24 parts by weight of acetone, and 50 parts by weight of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com