Manufacturing method of self-sensing micro-clamps with grippers of fiber optic fabry-perot interferometer

A technology of interferometer and micro-clamp, which is applied in the direction of instruments, optical waveguide and light guide, micro-structure technology, etc., can solve the problem that the gripper cannot realize the self-sensing of gripping parts and gripping force at the same time, so as to avoid electromagnetic interference, High precision and good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

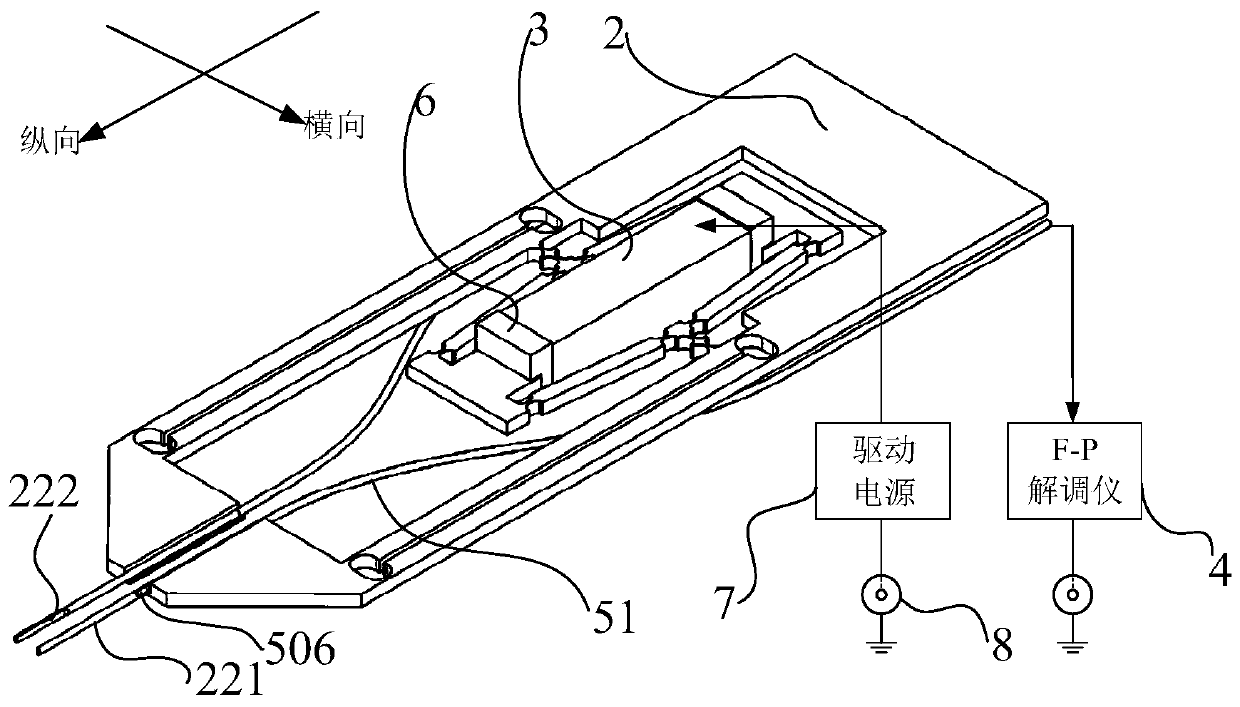

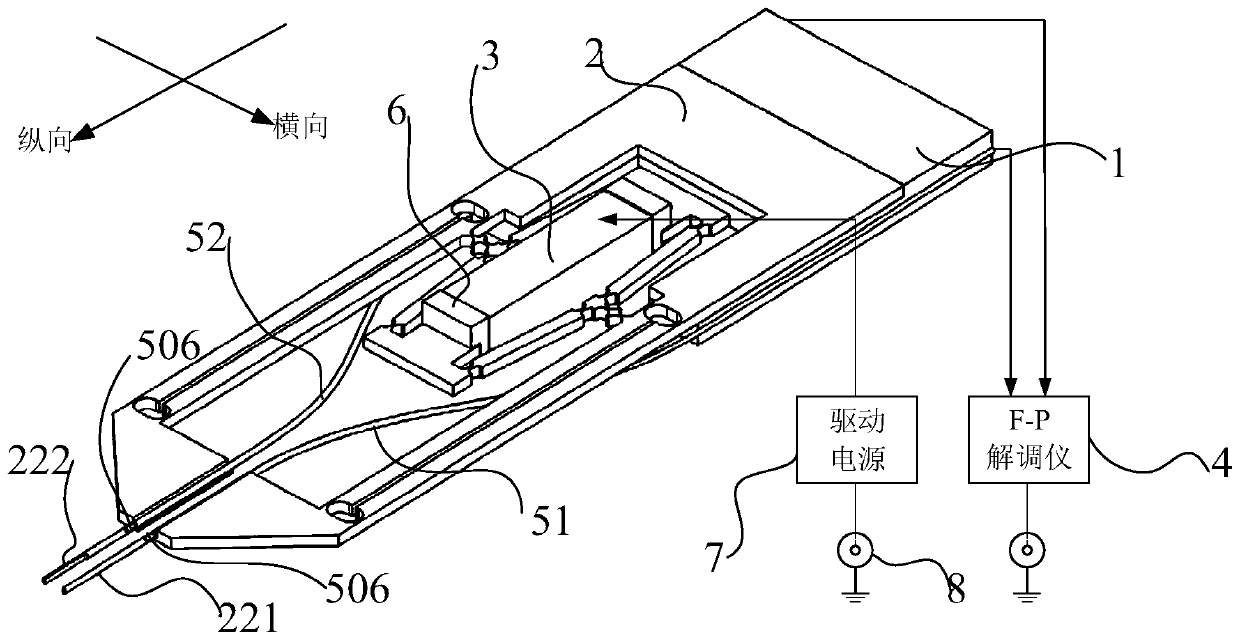

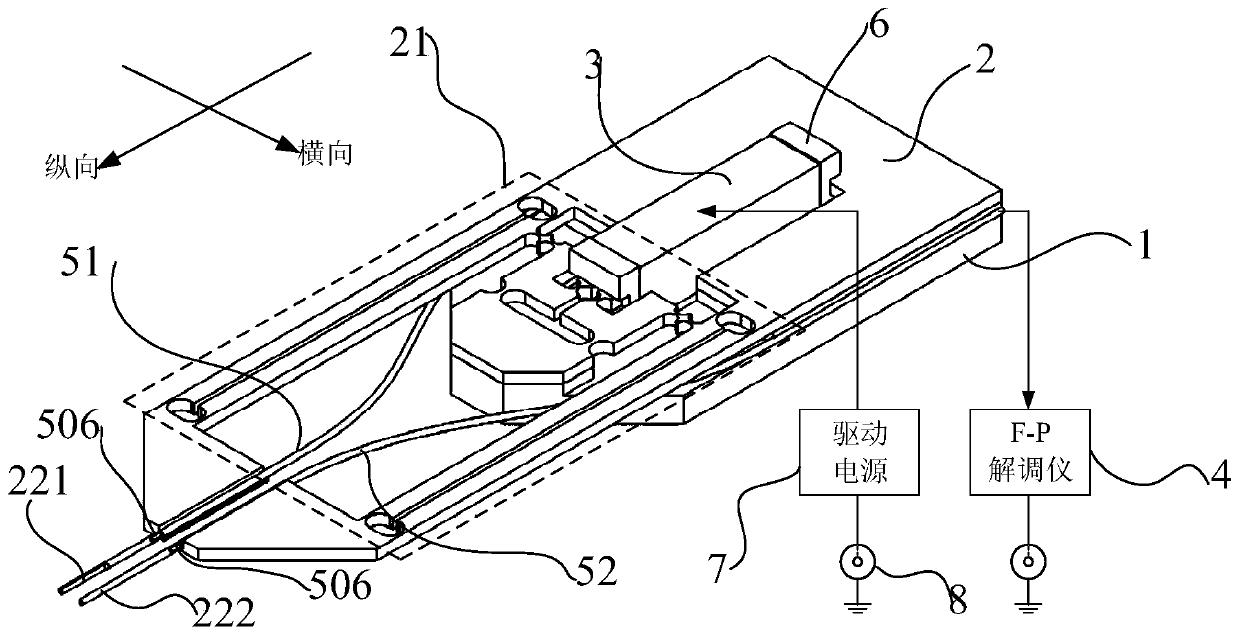

[0046] refer to Figure 1 to Figure 12 , the present invention provides a micro-clamp, comprising: a monolithic flexible mechanism 2, an actuator 3 installed in a cavity opened on the monolithic flexible mechanism 2, one or two optical fiber Fabry-Perot interferometers, The F-P demodulator 4 (Fabry-Perot demodulator) connected to the optical fiber Fabry-Perot interferometer, and the controller connected to the actuator 3 and the F-P demodulator 4, the The monolithic flexible mechanism 2 includes: a displacement amplifying mechanism 21, the input stage 211 of the displacement amplifying mechanism 21 abuts against the actuator 3, and the two output stages 212 of the displacement amplifying mechanism 21 are respectively connected with a jaw One said fiber optic Fabry-Perot interferometer corresponds to one said gripper, said fiber optic Fabry-Perot interferometer includes a clamping portion forming said gripper and is used to form said gripper to clamp a component to be gripped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com