Method and system for secondary nucleation and reuse of calcified anaerobic granular sludge

A technology of anaerobic granular sludge and secondary nucleation, applied in chemical instruments and methods, anaerobic digestion treatment, water/sludge/sewage treatment, etc. Achieve the effect of accelerating sludge granulation, avoiding potential pollution and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

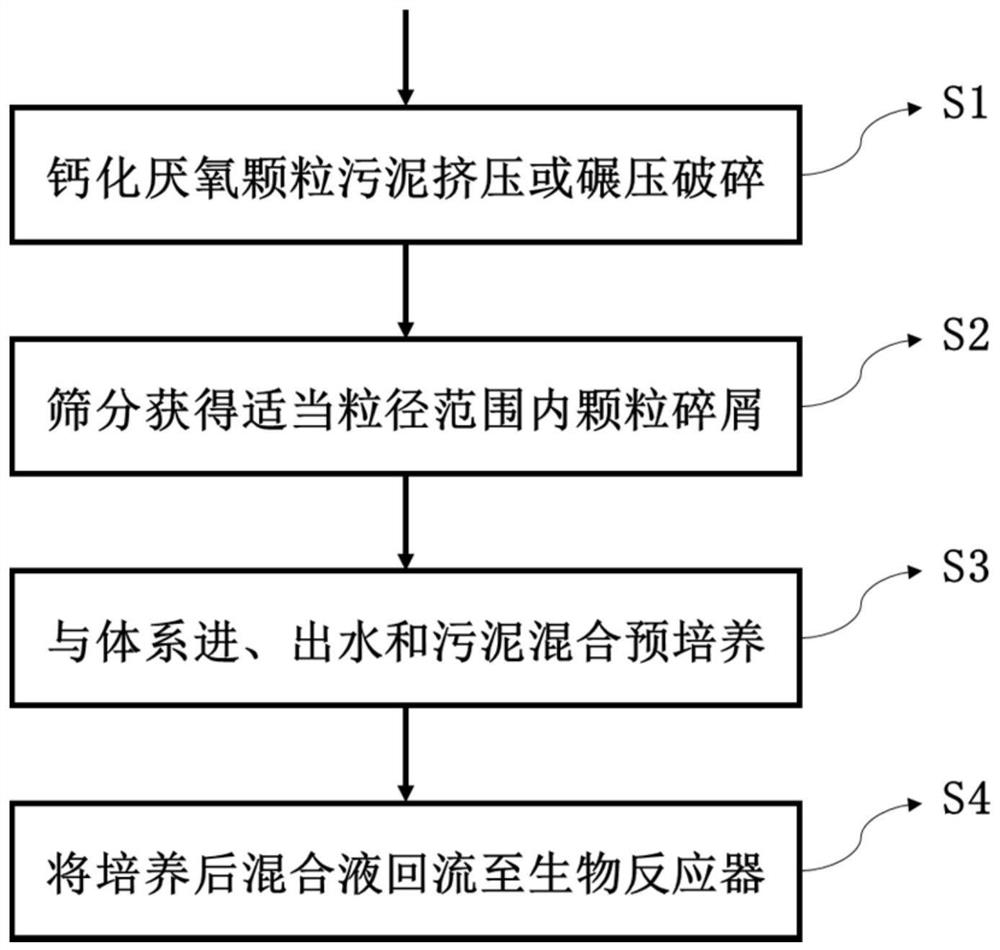

[0036] Such as figure 1 Shown is a specific flowchart of a method for secondary nucleation and reuse of calcified anaerobic granular sludge, including:

[0037] (1) Collect the calcified anaerobic granular sludge in the bioreactor, and squeeze or crush it;

[0038] (2) Screening the broken calcified anaerobic granular sludge to obtain calcified anaerobic granular sludge debris with a particle size within a certain range;

[0039] (3) The debris obtained is mixed with bioreactor inflow and outflow water and normal sludge for a certain period of time;

[0040] (4) Return the mixed cultured sludge to the bioreactor to promote secondary nucleation and accelerate sludge granulation.

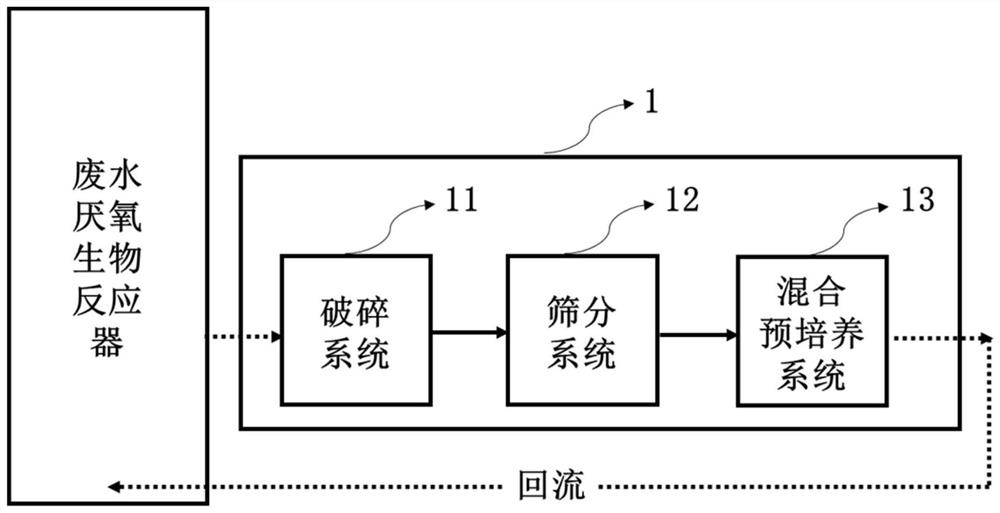

[0041] The components of a secondary nucleation and reuse system for calcified anaerobic granular sludge are as follows: figure 2 As shown, the system includes a crushing module, a screening module, a mixed cultivation module, and a sludge pumping and pumping module;

[0042] The crushing module ...

Embodiment 2

[0052] Others are the same as embodiment 1. In this example, the ratio of (influent: normal sludge: calcified granular sludge) was controlled to be 6:2:2 during mixed culture. Preferably, the stirring speed in the continuous stirred reactor (CSTR) is 20 rpm; the cultivation temperature is 30° C.; the bioreactor does not reflux, and the water inlet is replaced every 2 days. After about 40 days of operation, the following conditions are obtained: Similar to the granular sludge with higher biological activity after secondary nucleation in Example 1.

Embodiment 3

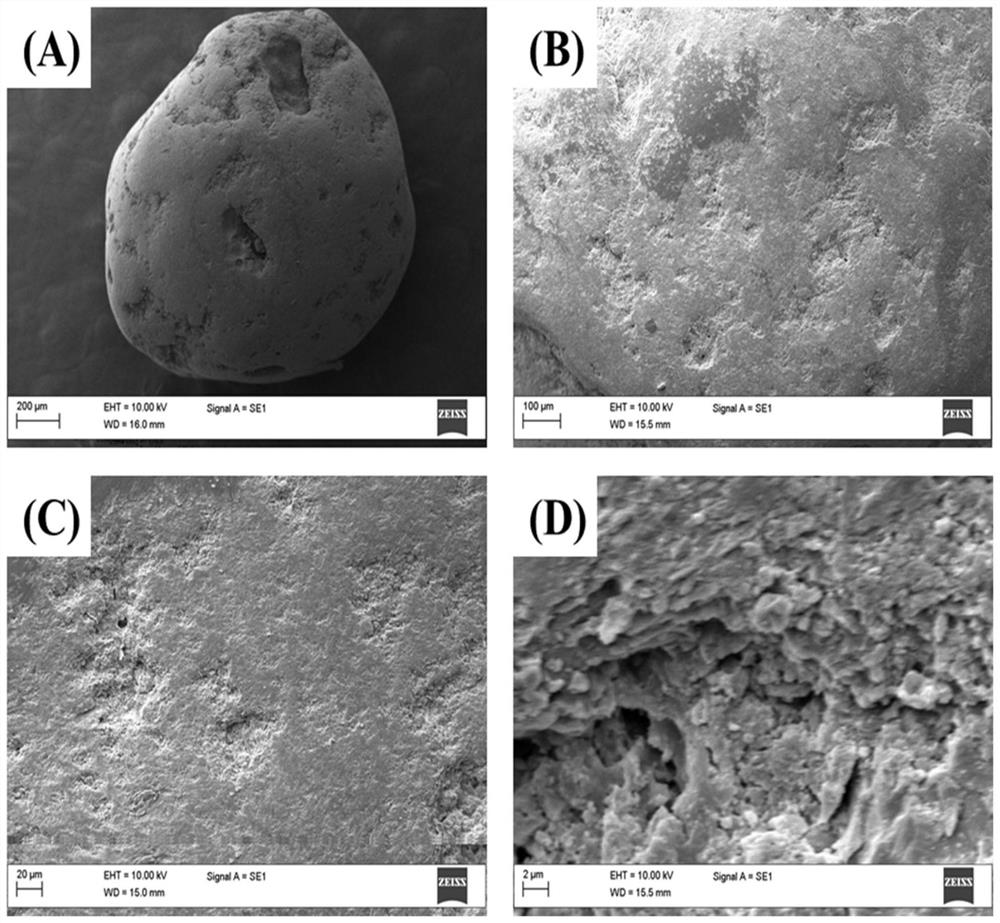

[0054] The method and system for secondary nucleation and reuse of calcified anaerobic granular sludge are the same as in Example 1. In this example, the granular sludge discharged from the bottom of the anaerobic tower of a citric acid processing enterprise was collected and crushed under the action of the rolling crushing module, and the rolling intensity was controlled so that the pressure on some calcified particles was approximately 30 N / cm2. The crushing time of the rolling crushing module is 10 minutes, and the wheel rolling speed is controlled at 5 rpm. During the crushing process, water is properly supplemented to keep the sludge particles and their debris moist.

[0055] After the particle debris passes through the screening module, the sludge particle debris with a particle size between 0.1 and 0.5mm is obtained. After collection, it is mixed with the reactor inlet and outlet water and normal sludge. Unloading valve, top have sample inlet, exhaust hole, there is cul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com