Method for multistage anaerobic treatment of etimicin sulfate production wastewater

A technology for etimicin sulfate and production wastewater, which is applied in anaerobic digestion treatment, water/sewage multi-stage treatment, multi-stage water treatment, etc. Lack of problems such as reducing COD and residual antibiotics, reducing emissions and environmental risks, and reducing the use of pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

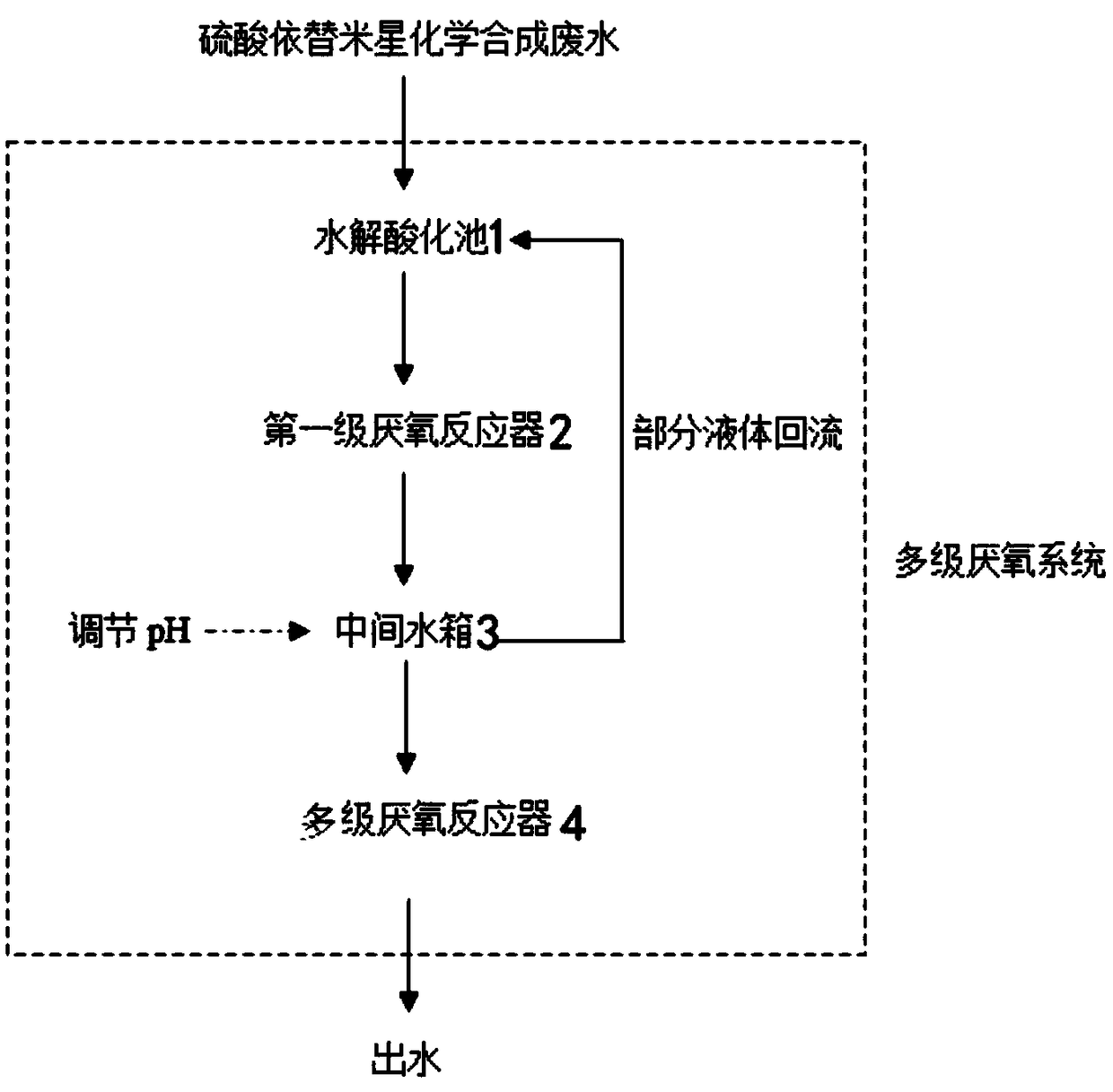

[0027] Embodiment 1: as figure 1 As shown, the treatment equipment of the present invention is made of hydrolytic acidification tank, 3 anaerobic reactors and 1 intermediate water tank, and intermediate water tank is positioned between the first-stage anaerobic reactor and the second-stage anaerobic reactor, and the second-stage Between the anaerobic reactor and the third-stage anaerobic reactor, water flows by gravity.

[0028] Pump high-concentration etimicin sulfate chemically synthesized wastewater (COD is 16230mg / L, gentamicin C1a content is 32.2mg / L) into the hydrolytic acidification tank with a volume of 0.5m 3 , the inflow flow is 0.1m 3 / h, adjust the oxidation-reduction potential in the hydrolytic acidification pool to -100~50mV, and control the pH in the hydrolytic acidification pool to 6.5±0.2.

[0029] Pump the effluent from the hydrolytic acidification tank into the first-stage anaerobic reactor with a flow rate of 0.15m 3 / h, the effective volume of the first...

Embodiment 2

[0032] Embodiment 2: as figure 1 As shown, the treatment equipment consists of a hydrolytic acidification tank, a first-stage anaerobic reactor, an intermediate water tank, and a second-stage anaerobic reactor in series.

[0033] Pump high-concentration etimicin sulfate chemically synthesized wastewater (COD is 15294mg / L, gentamicin C1a content is 30.7mg / L) into the hydrolytic acidification tank with a volume of 250m 3 , the inflow flow rate is 42m 3 / h, adjust the oxidation-reduction potential in the hydrolytic acidification pool to -80~50mV, and control the pH in the hydrolytic acidification pool to 6.5±0.2.

[0034] Pump the effluent from the hydrolytic acidification tank into the first-stage anaerobic reactor with a flow rate of 63m3 / h, and the effective volume of the first-stage anaerobic reactor is 3.75m 3 . The effluent treated by the first-stage anaerobic reactor overflows into the intermediate water tank, and NaOH is added to the intermediate water tank to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com